CNC Rapid

Steel/Stainless steel/Brass/Aluminium CNC Service

Upload your CAD files, get a CNC machining services price estimate promptly, get your custom CNC parts into production.

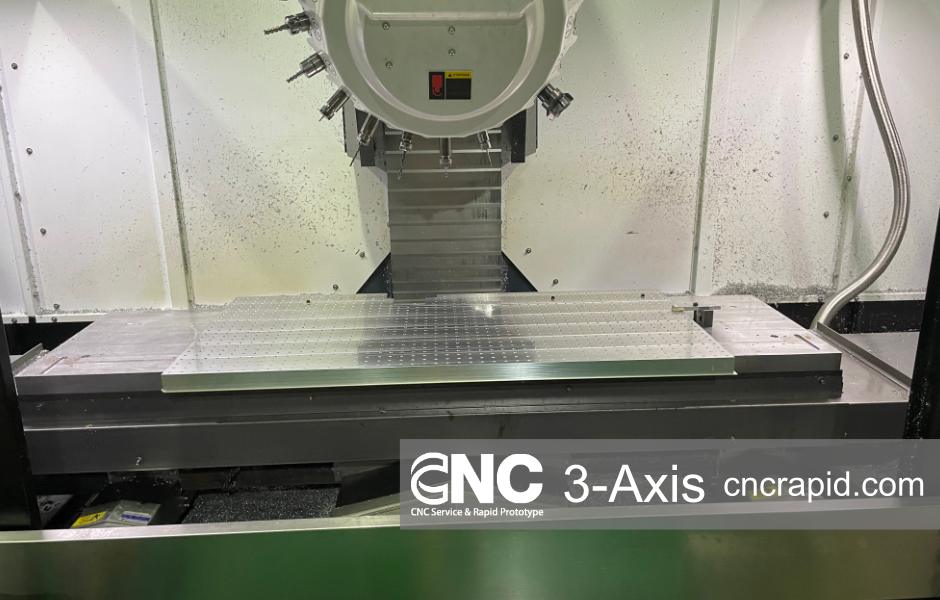

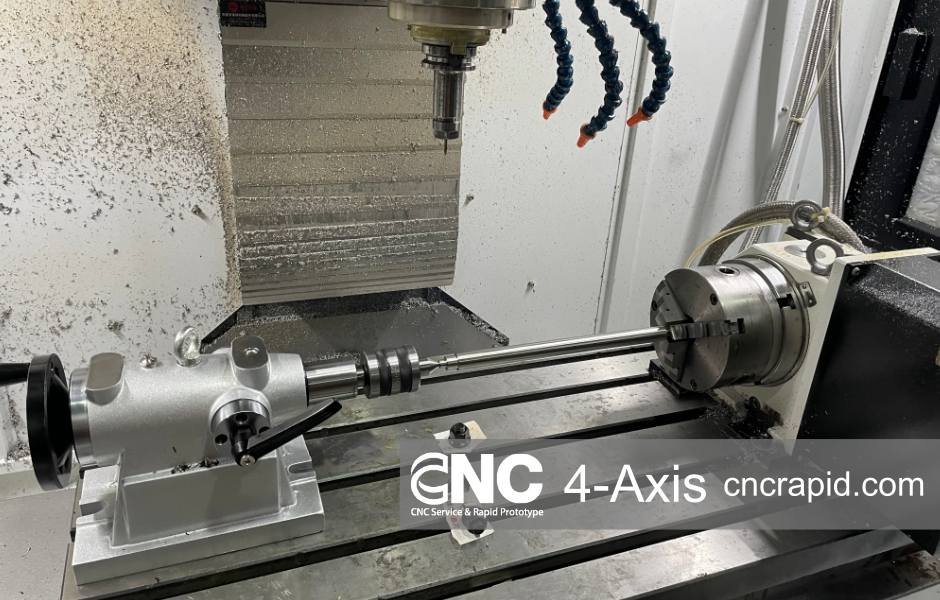

CNC Machining China: From prototyping to full production runs. Our 3 axis, 4 axis, and 3+2 axis CNC milling centers will allow you to produce highly accurate and quality parts to meet even your most stringent requirements.

Maximum part size for 3-axis, 4-axis and 3+2-axis CNC milling is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

Available materials for CNC machining at DFM Rapid

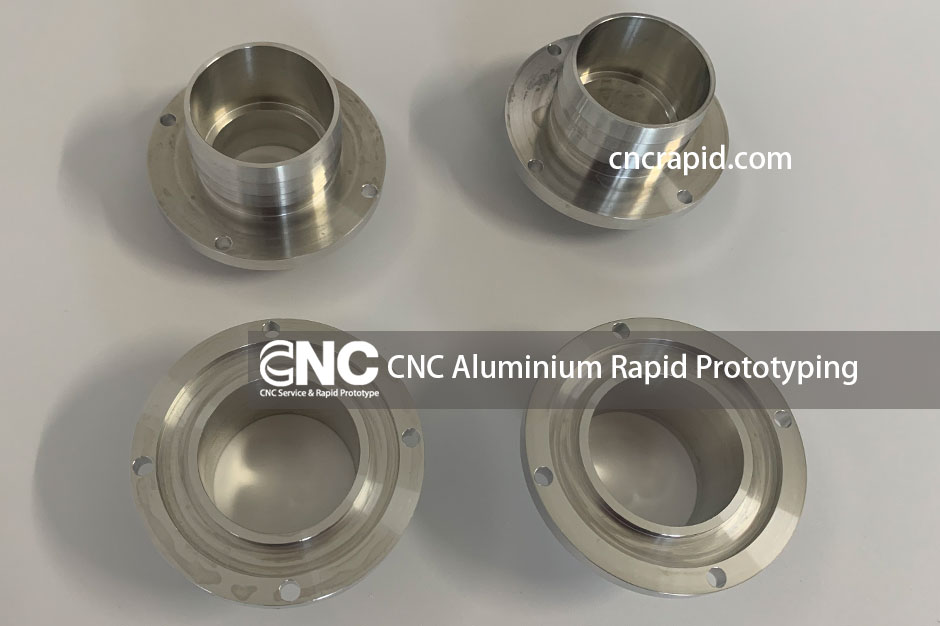

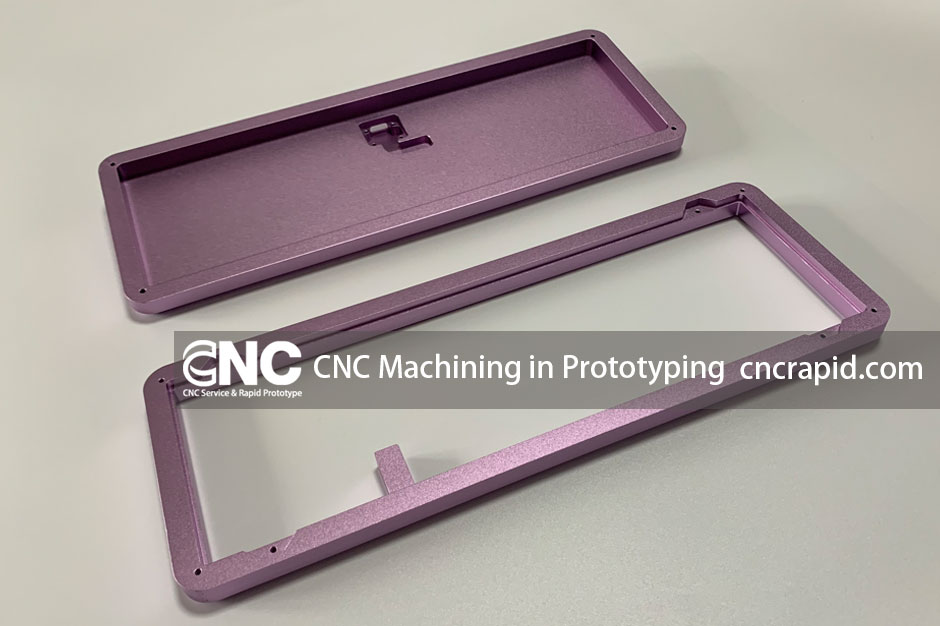

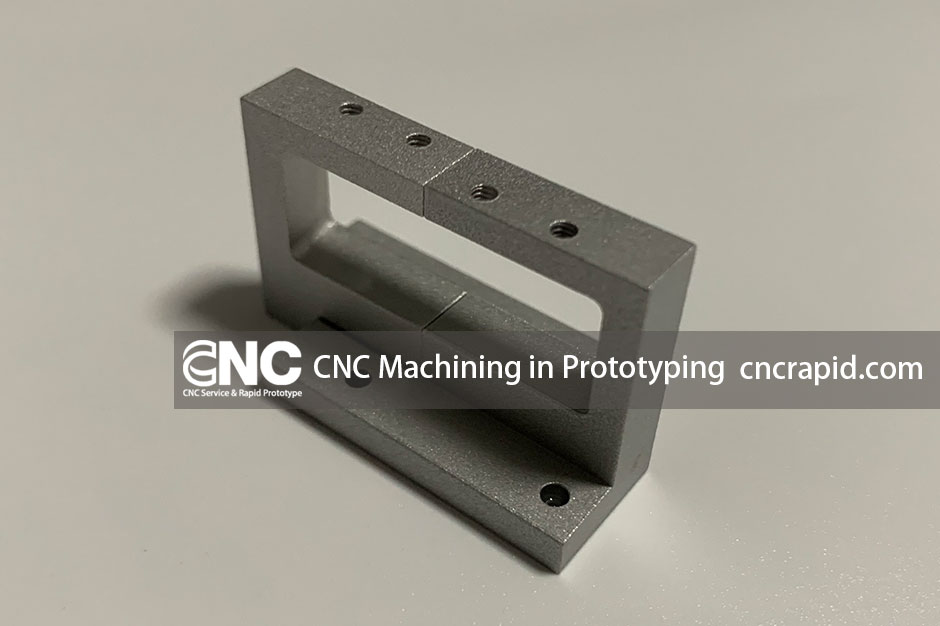

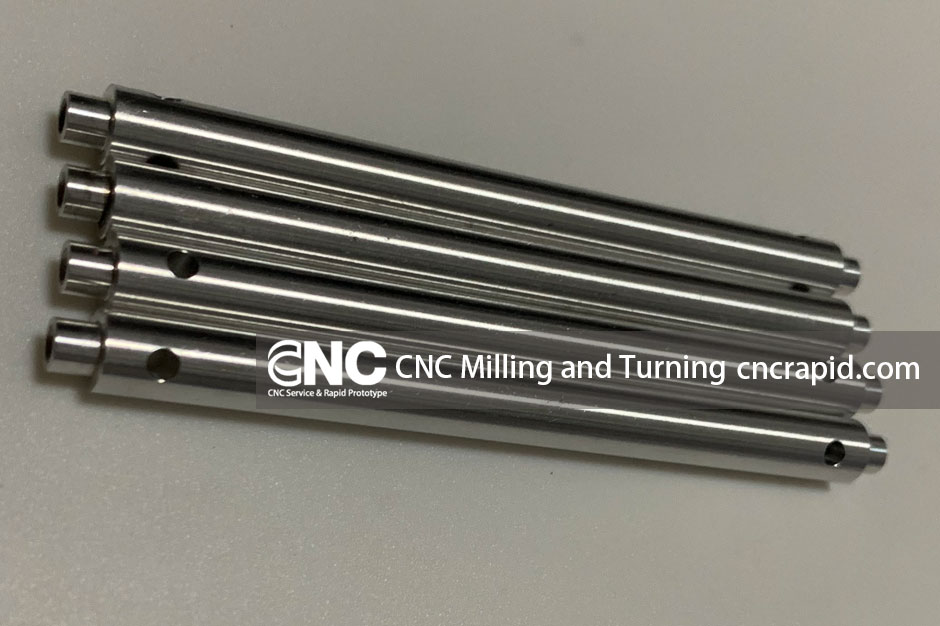

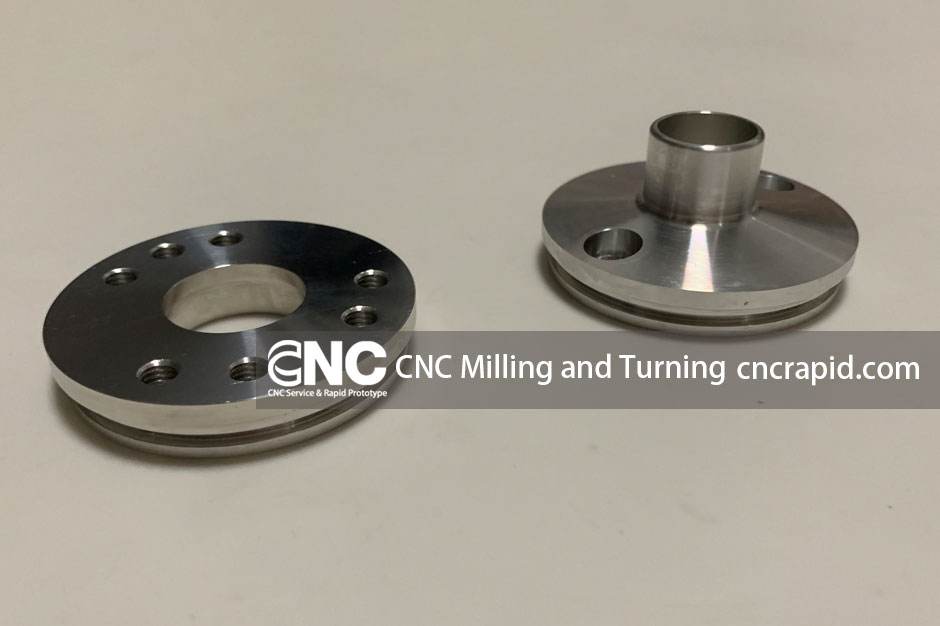

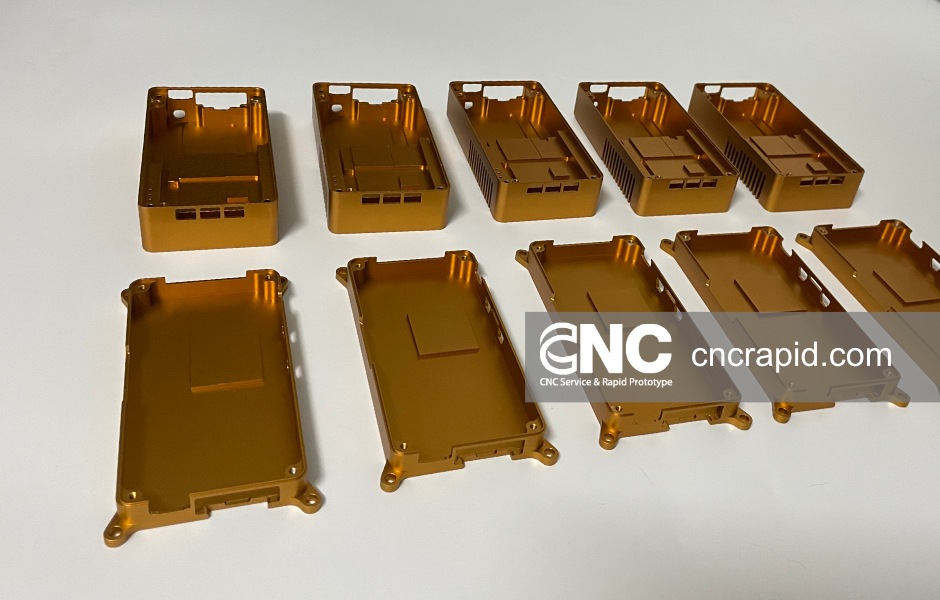

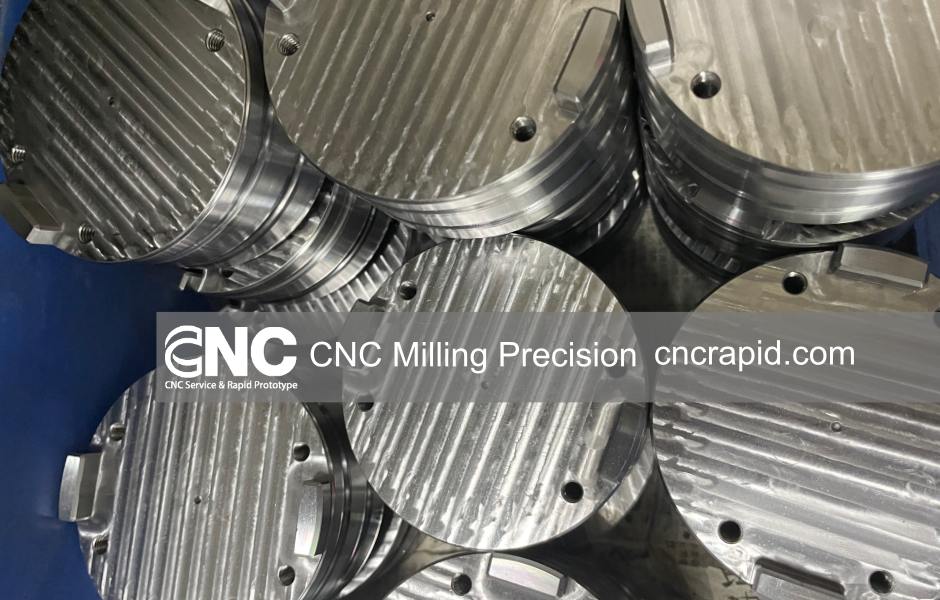

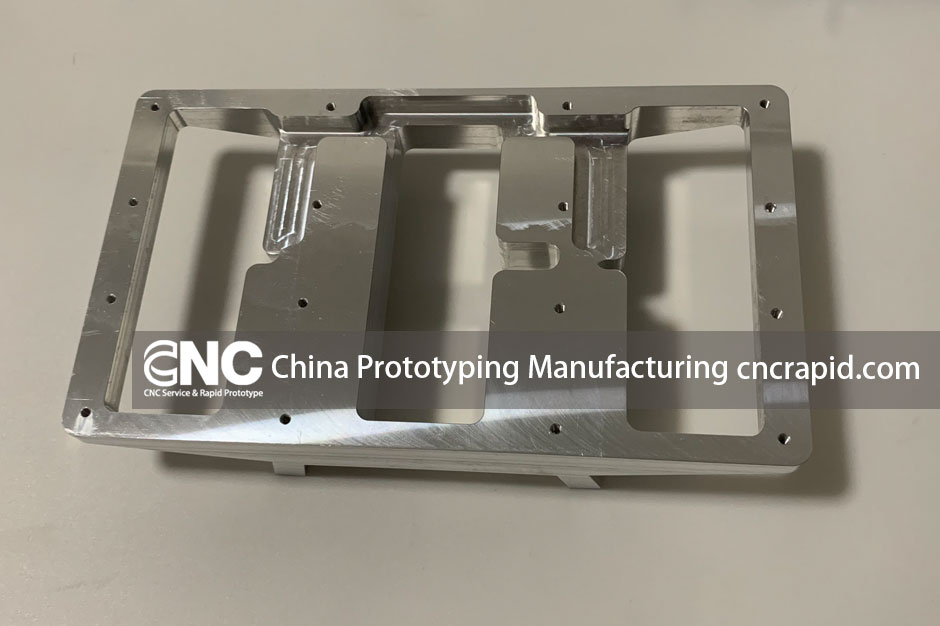

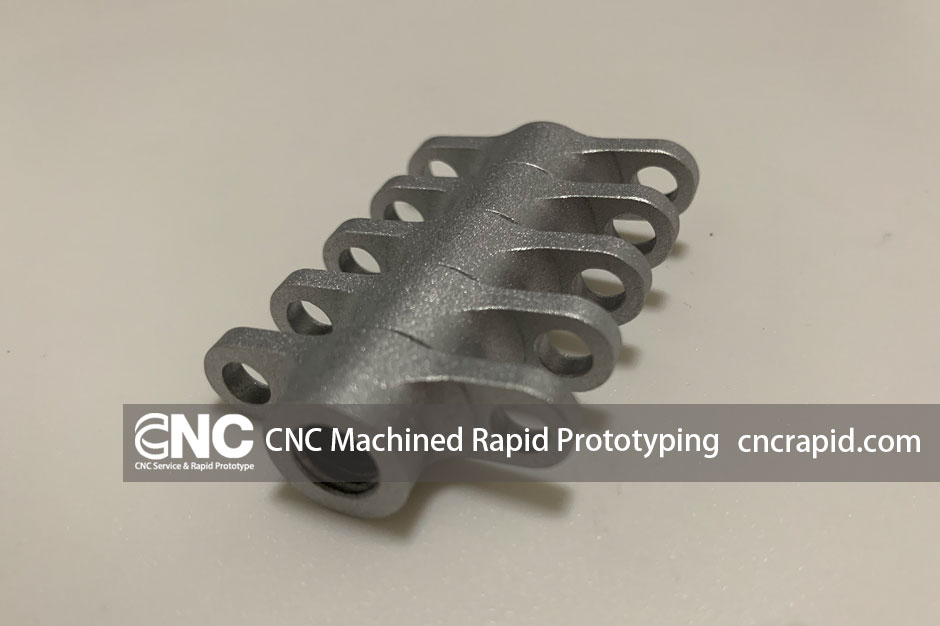

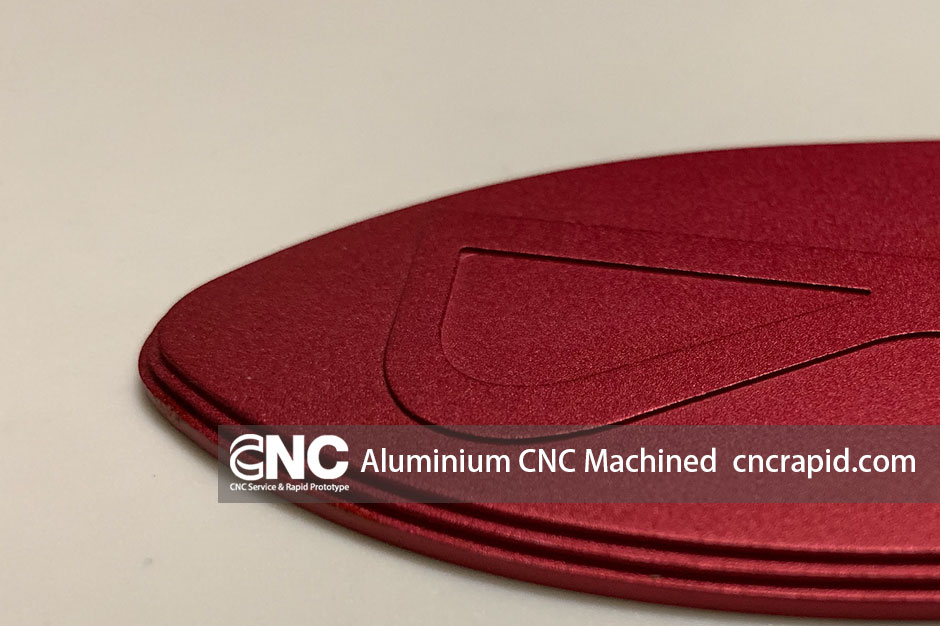

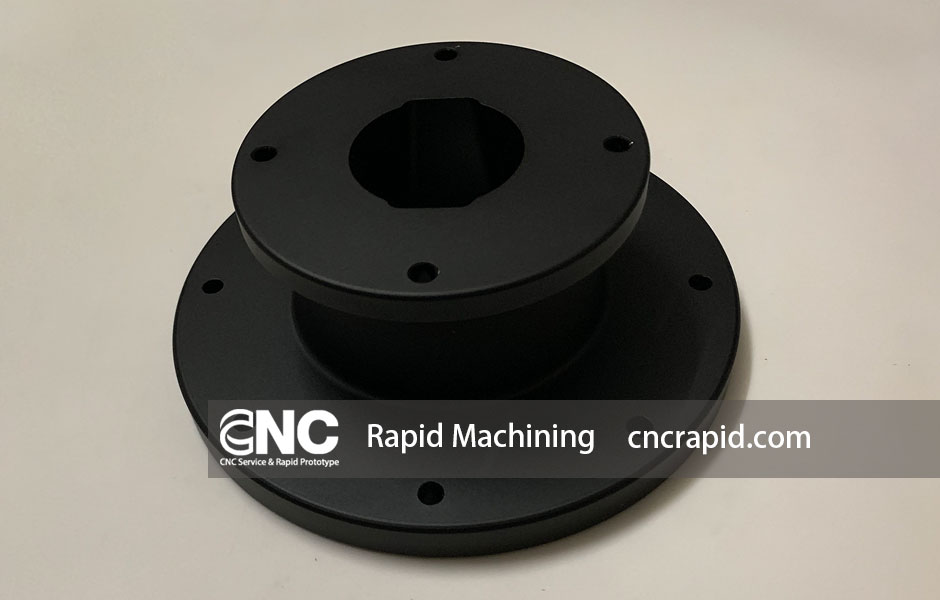

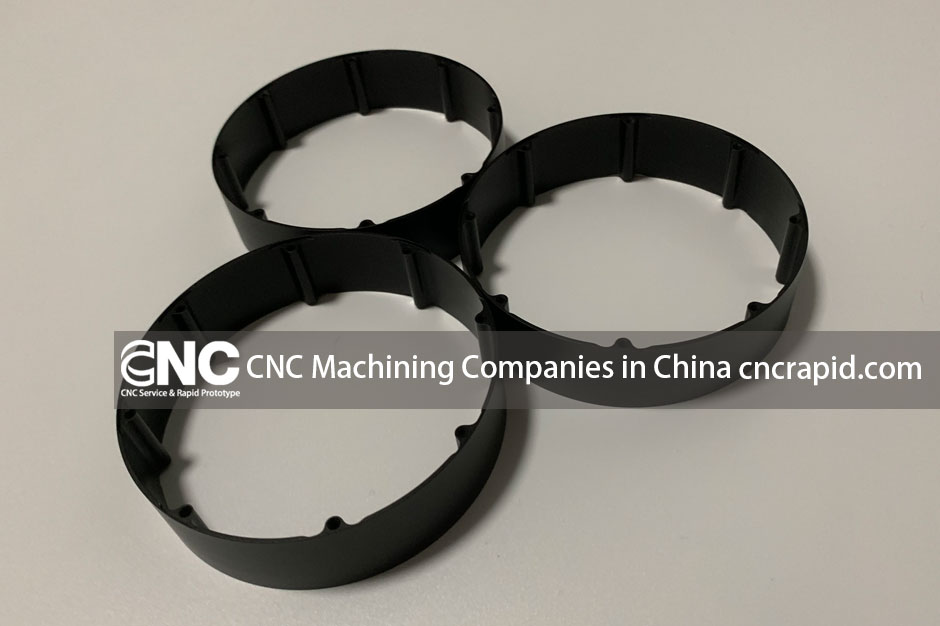

Gallery of CNC machined parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Available surface finishes for CNC machining

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

This is our standard finish. Parts are machined and deburred, sharp edges are chamfered.

Smooth machining is like an ‘As machined’ finish but with slightly less evident machine marks. Parts are machined at a lower feed, no hand polishing is applied.

Parts are bead blasted and anodized type II. Ideal for increasing the corrosion resistance of the part.

Parts are bead blasted and an anodizing type III coating is directly applied to the surface. Ideal to improve corrosion and wear resistance of components.

Parts are brushed and then anodized type II. Ideal for increasing the corrosion resistance of the part. Typically results in a glossy color.

Powder coating is a strong, wear-resistant finish that is compatible with all metal materials.

Applicable to numerous substrates, black chrome plating is an electrochemical procedure that enhances wear resistance and provides a distinguished, dark aesthetic.

Tolerances

We adhere to the ISO 2768-f standards for CNC machining. Our standard tolerances are +/-0.1 mm (.005”), which are well-suited for most commercial and industrial applications. However, we can achieve tighter tolerances of +/-0.01mm (0.00039”) for specialized projects. Please consult with us if you require closer tolerances for your unique requirements.

Specialist industries

China CNC Machining Services

From 1 to 10000+ Parts

What Is a Riveting Head? CNC Machined Steel Riveting Tools Explained

At CNC Rapid, we recently completed several batches of custom-machined steel components. Among them, a few parts are called “rivet heads”, a name that often causes confusion. Many people think of rivet heads as the [...]

Custom Fixture and Connector Parts by CNC Rapid

At CNC Rapid, we specialize in producing custom fixture and connector parts that meet the demands of modern engineering and industrial applications. The parts shown here were recently machined from high-strength steel, demonstrating our precision [...]

1045 Steel Rod-End Cap CNC Machined Part

This part supports and guides the piston rod, carries the dust wiper and primary seals, and bolts to the cylinder tube via a flanged pattern. Below is a practical overview of material choice, machining process, [...]