The Role of 3-Axis CNC in Production

3-Axis CNC machining is an indispensable asset in the engineering world, offering a balance of precision, efficiency, and versatility.

3-Axis CNC Machining: A Comprehensive Overview for Engineers

Manufacturing and precision engineering have long recognized 3-Axis CNC machining as a cornerstone. This article aims to provide a detailed insight into the capabilities, applications, and significance of 3-Axis CNC in modern engineering.

Introduction to 3-Axis CNC Machining

3-Axis CNC machining refers to a machine’s capability to move a tool or a part in three linear directions: X (side to side), Y (front to back), and Z (up and down). This tri-directional movement allows for intricate and precise machining operations on a workpiece.

Key Advantages of 3-Axis CNC Machining

- Precision and Accuracy: With computer-aided control, 3-Axis CNC machines can achieve tight tolerances, ensuring parts are consistently produced to exact specifications.

- Efficiency: Automated machining processes mean faster production times and reduced manual labor.

- Versatility: Suitable for a wide range of materials, including metals, plastics, and ceramics.

Comparative Analysis: 3-Axis vs. Multi-Axis Machining

While 3-Axis CNC machines offer a significant degree of freedom, multi-axis machines, such as 5-Axis CNCs, provide additional rotational movements around the X and Y axes. This allows for more complex geometries and reduces the need for repositioning the workpiece. However, 3-Axis machines often suffice for a vast majority of machining tasks and come at a more affordable price point.

Applications in Modern Engineering

From aerospace components to automotive parts, 3-Axis CNC machining is integral in producing parts that require high precision and consistent repeatability. Its applications span across industries, making it a fundamental tool in modern manufacturing.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

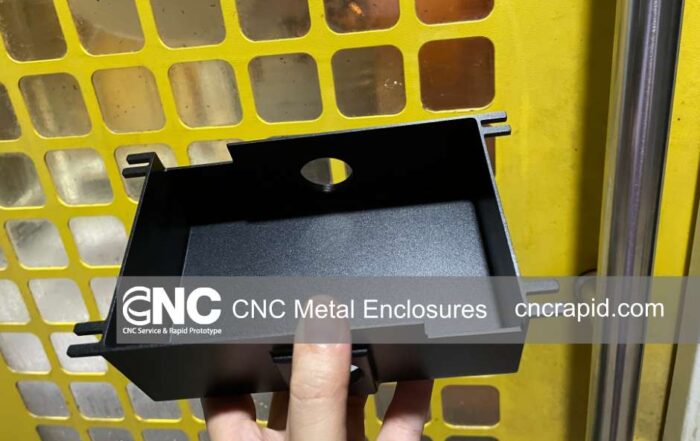

CNC Machined Aluminum Housings

As electronic devices become more powerful and compact, standard off-the-shelf enclosures are often no longer sufficient. High-performance electronics—such as industrial controllers, audio amplifiers, and medical devices—require robust protection, precise mounting points, and excellent thermal management. [...]

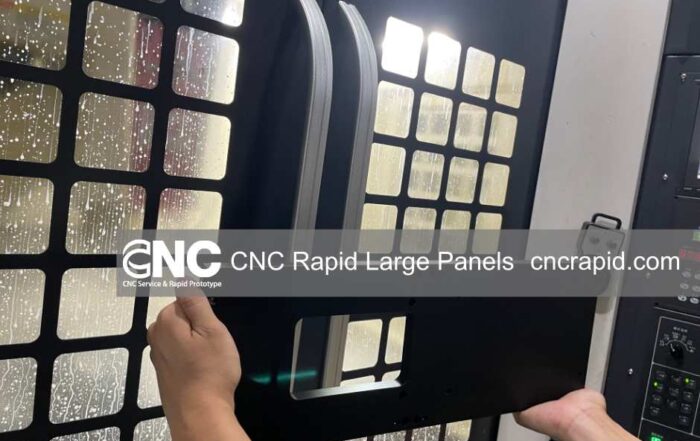

Machining Large CNC Panels: How We Maintain Perfect Flatness

Manufacturing small, complex parts is one thing, but machining Large CNC Panels presents a completely different set of challenges. When you are dealing with large aluminum base plates or mounting panels, the biggest enemy is [...]

Aluminum Base Plate Solutions: CNC-Milled Foundations for Reliable PCBs

When an electronic design needs both mechanical rigidity and efficient heat spreading, a aluminum base plate often offers the lightest and most straightforward answer. Instead of relying on fragile standoffs or heavy steel backers, a [...]

Custom 6061-T6 Aluminium PCB Housing – CNC Rapid

CNC Rapid is a precision-machining supplier based in Dongguan, China. More than forty percent of our yearly shipments are custom aluminium enclosures for industrial electronics, instrumentation, and IoT devices. Among the alloys we handle, 6061-T6 [...]

CNC Machining Angled Holes in Aluminum Parts

Modern electronic enclosures, lightweight gearboxes, and heat-dissipating housings often rely on slanted or compound-angle passages for wire routing, oil flow, or fastener access. Machining those angled holes in aluminum—while holding both position and surface-finish requirements—demands [...]

Precision CNC Metal Enclosures for Electronics by CNC Rapid

Whether you’re protecting a sensitive IoT sensor or a full‑featured control module, the metal enclosure you choose can make—or break—performance. At CNC Rapid, we machine custom enclosures from 6061‑T6 aluminum and finish them with a deep [...]