CNC Milling Service

From rapid prototyping to our specialized Aluminum CNC Machining Service, simply upload your CAD files to receive a prompt price estimate and get your parts into production efficiently.

Our CNC milling service capabilities

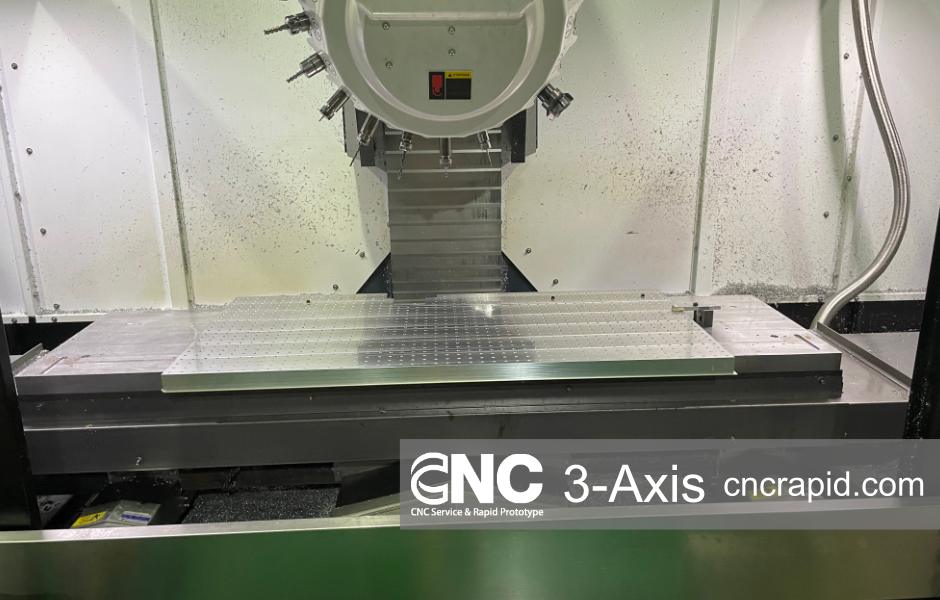

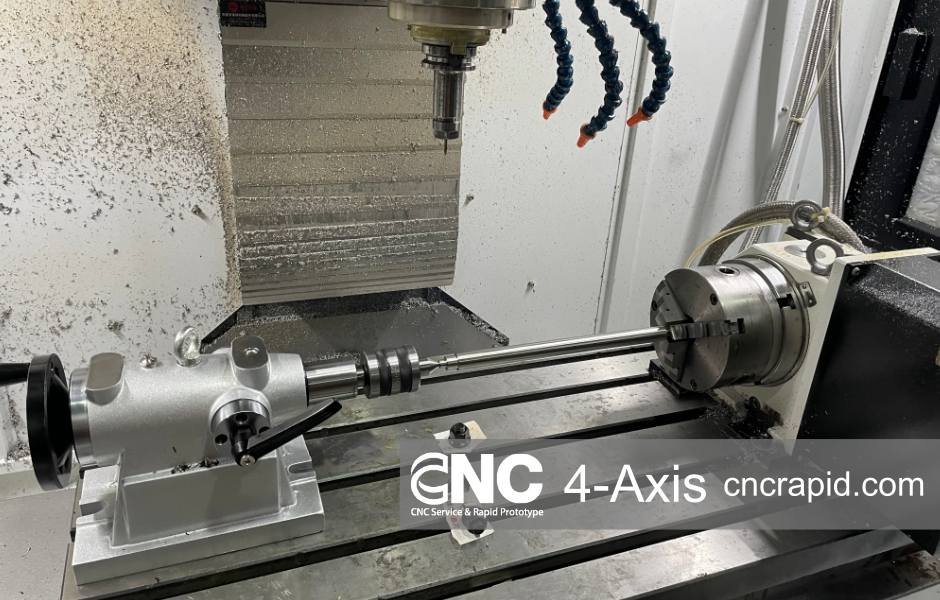

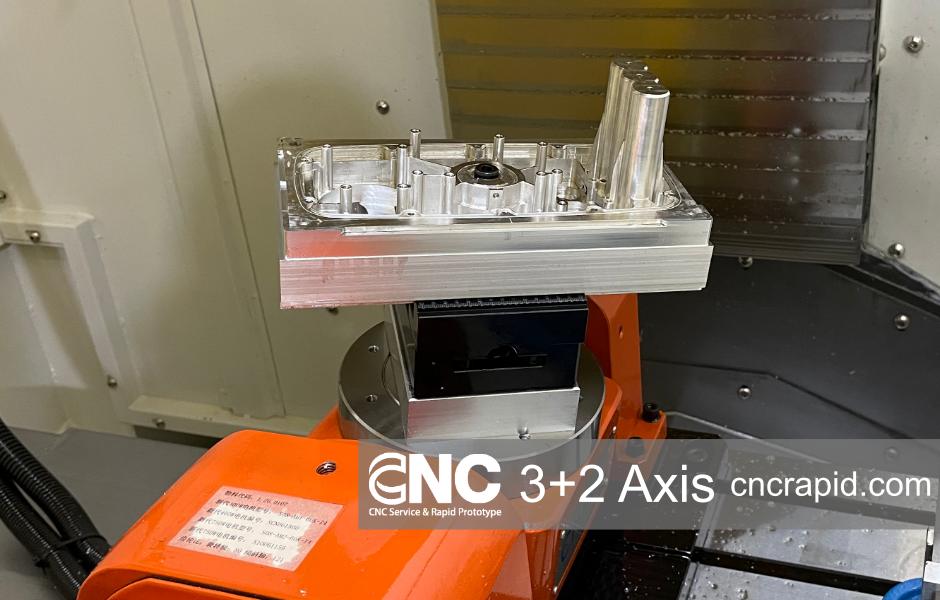

From prototyping to full production runs. Our 3 axis, 4 axis, and 3+2 axis CNC milling centers will allow you to produce highly accurate and quality parts to meet even your most stringent requirements.

Maximum part size for 3-axis, 4-axis and 3+2-axis CNC milling is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

Available materials for CNC machining at DFM Rapid

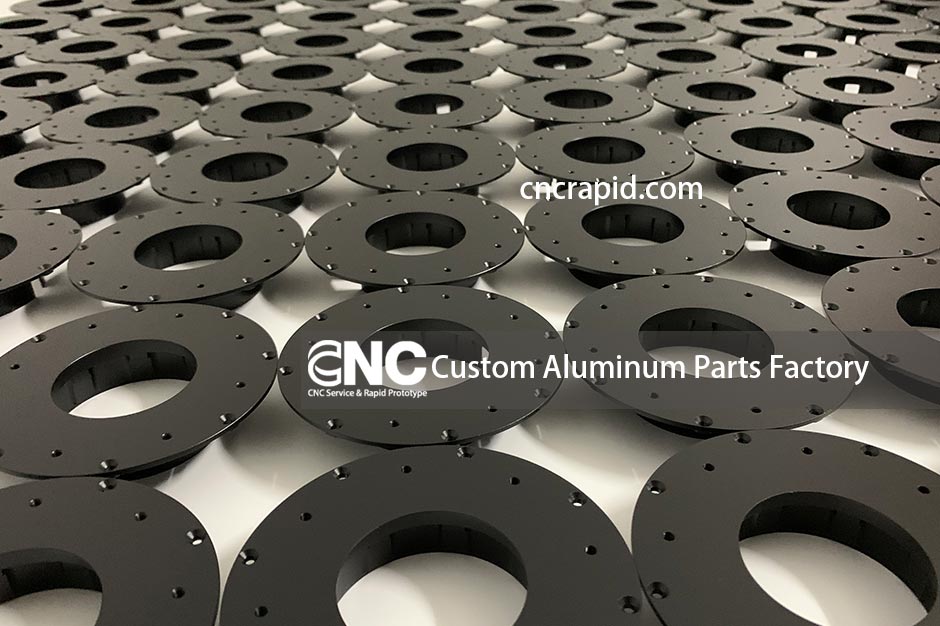

Gallery of CNC machined parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Tolerances

We adhere to the ISO 2768-f standards for CNC machining. Our standard tolerances are +/-0.1 mm (.005”), which are well-suited for most commercial and industrial applications. However, we can achieve tighter tolerances of +/-0.01mm (0.00039”) for specialized projects. Please consult with us if you require closer tolerances for your unique requirements.

From 1 to 10000+ Parts

Precision CNC Custom Parts Prototyping by CNC Rapid

Every product starts as an idea, and the faster that idea becomes a physical part you can hold, test, and refine, the sooner it reaches the market. At CNC Rapid, CNC custom parts prototyping bridges [...]

CNC Machining of Optical Components by CNC Rapid

When light has only a few microns of wiggle room before image quality degrades, every mechanical interface around an optic must be machined with the same rigor as the lens itself. Modern CNC milling and [...]

Custom CNC Prototypes with Black Acetal and Metal Parts

At CNC Rapid, we specialize in delivering high-quality, custom CNC prototypes for various industries. One such example is a CNC-machined prototype made from black acetal combined with precision metal components. This unique assembly highlights our [...]

Custom CNC Machined Parts for the Medical Industry

At CNC Rapid, we understand the critical importance of precision, quality, and reliability in the medical industry. Our extensive experience in CNC Machining China allows us to produce high-quality custom parts for medical devices, meeting [...]

Prototype CNC Services for Electronics and Automotive Industries

Prototype CNC services are indispensable in the electronics and automotive industries, providing the precision, speed, and flexibility needed to stay ahead in competitive markets. CNC Rapid is dedicated to helping you achieve your product development [...]

The Advantages of Rapid CNC Production Machined Parts

From prototype to production, rapid CNC production machined parts offer numerous advantages that can significantly enhance manufacturing processes. The speed, precision, cost-effectiveness, and scalability of CNC technology make it an invaluable tool for modern industries. [...]