The Significance of Copper C101 in CNC Machining:

Copper C101 offers exceptional electrical conductivity due to its 99.99% purity. Its high purity and performance make it a preferred choice for CNC machining.

Copper C101, commonly known as Oxygen-Free Electronic (OFE) copper, is renowned for its impressive purity levels. This material offers unparalleled electrical conductivity, making it a prime choice in the CNC machining world.

Chemical Composition: Copper C101 boasts an impressive 99.99% copper content, with the remaining 0.01% consisting of trace elements, ensuring minimal impurities. This high copper content is the reason behind its superior electrical conductivity.

Key Features:

- Electrical Conductivity: C101 copper is one of the best conductors of electricity, thanks to its high purity levels.

- Thermal Conductivity: Its excellent thermal properties make it ideal for applications requiring efficient heat transfer.

- Machinability: While C101 is not the easiest copper to machine due to its softness, it provides a smooth finish when machined correctly.

- Corrosion Resistance: It offers good resistance to atmospheric corrosion, making it suitable for various environments.

Machining Insights: Machining C101 requires sharp tools to ensure clean cuts and to prevent the material from sticking to the tool. Given its soft nature, slow speeds and feeds are recommended to achieve precision and to avoid deformation.

Applications:

- Electrical Components: Its unmatched conductivity makes C101 the preferred choice for high-end electrical connectors, terminals, and conductors.

- Heat Sinks: Its ability to transfer heat efficiently makes it a top pick for electronic heat sinks.

- Architectural Features: Its bright, shiny appearance combined with its corrosion resistance makes it a favorite for decorative and architectural applications.

Design Tips for Engineers:

- For parts requiring superior electrical conductivity, C101 should be your first choice.

- Leverage its thermal properties for applications that demand efficient heat dissipation.

- Given its softness, designs requiring intricate shapes can benefit from C101, but care should be taken during machining.

Copper C101 combines purity with excellent electrical and thermal properties, solidifying its position as a top-tier choice for CNC machining. For applications that demand the best in conductivity and appearance, C101 is the material of choice.

Copper C110 vs. Copper C101

| Feature/Property | Copper C110 | Copper C101 |

|---|---|---|

| Purity | 99.9% | 99.99% |

| Electrical Conductivity | Excellent, but slightly less than C101 due to its slightly lower purity | Superior, one of the best conductors of electricity due to its high purity |

| Thermal Conductivity | Excellent | Slightly better than C110 due to higher purity |

| Machinability | Good, but care is needed due to its softness | Similar to C110, but its higher purity might pose some challenges |

| Corrosion Resistance | Good resistance to atmospheric corrosion | Similar resistance to C110 |

| Applications | Electrical connectors, terminals, conductors, heat sinks, architectural features | High-end electrical connectors, terminals, conductors, electronic heat sinks, decorative and architectural applications |

While both Copper C110 and Copper C101 are excellent choices for CNC machining, the decision between them often comes down to specific requirements. C101’s higher purity makes it the go-to for applications demanding the utmost in electrical conductivity, while C110 is more commonly used for a broader range of applications.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

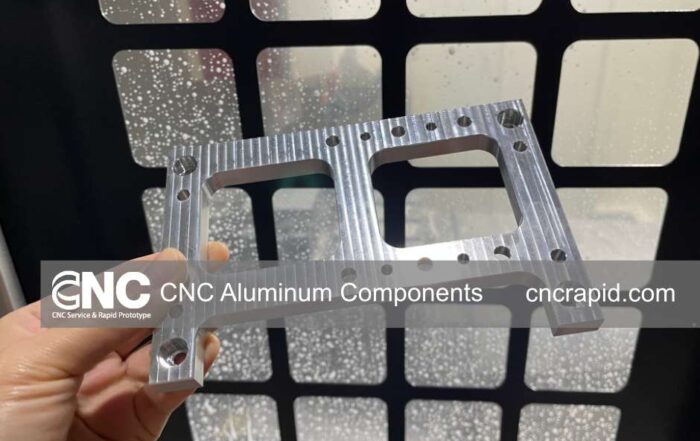

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

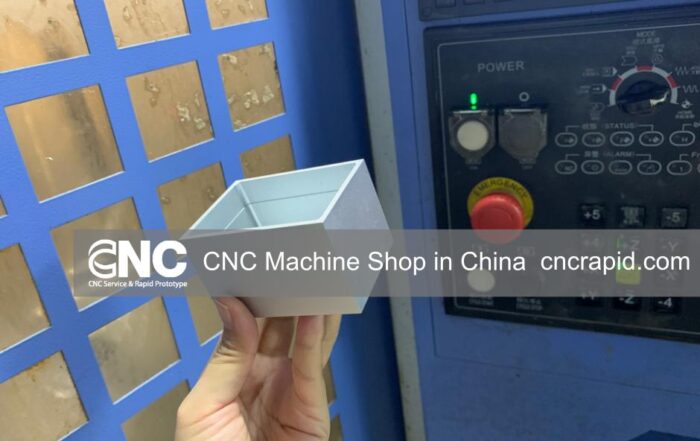

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]