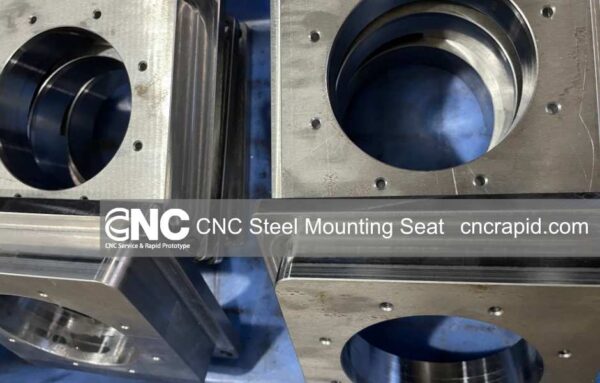

At CNC Rapid, we provide precision CNC machining services for a wide range of custom metal components. One of our recent projects is a custom CNC Machined Steel Mounting Seat, carefully engineered and machined to support industrial machinery and equipment. This component highlights our ability to deliver durable, reliable, and high-precision steel parts that meet the exact requirements of our clients.

Why CNC Machined Steel Mounting Seat

A mounting seat is an essential part in many mechanical assemblies. It provides a stable foundation for equipment, ensuring accurate positioning and long-term durability. For heavy-duty applications, steel is often the preferred material due to its high strength, rigidity, and resistance to wear.

Custom steel mounting seats are commonly used in:

- Machinery frameworks and support structures

- Industrial automation systems

- Measuring and testing equipment

- Construction and engineering projects

By machining these components to exact specifications, CNC Rapid ensures that they fit seamlessly into larger assemblies and deliver dependable performance.

Why Steel Is the Right Choice

Steel is one of the most reliable materials for mounting applications. Compared to aluminum, steel offers:

- Higher load-bearing capacity for heavy equipment

- Improved dimensional stability under stress

- Excellent wear resistance for long service life

- Greater rigidity to minimize vibration

When combined with CNC machining, these advantages result in a mounting seat that can handle demanding operating conditions while maintaining precision and consistency.

CNC Machining Process for the Mounting Seat

Producing a custom steel mounting seat requires both advanced equipment and technical expertise. At CNC Rapid, our process includes:

- Material Selection – Choosing the right grade of steel to balance strength, machinability, and cost-effectiveness.

- CNC Milling & Turning – Creating precise geometries, flat surfaces, and mounting holes with tight tolerances.

- Boring and Drilling – Ensuring accurate alignment features for installation.

- Surface Treatment – Deburring, grinding, and applying protective coatings if required.

- Quality Inspection – Using tools such as calipers, micrometers, and CMM to confirm all dimensions.

This systematic approach guarantees accuracy, repeatability, and high-quality results for every mounting seat we produce.

Meeting Customer Requirements

For this project, the client provided detailed CAD files and requested specific tolerances. Our engineering team worked closely with them to confirm design details, optimize manufacturability, and then carried out machining with strict adherence to the drawings.

The finished steel mounting seat achieved excellent dimensional accuracy and surface quality, ensuring it could be integrated directly into the client’s system without modification.

Quality You Can Trust

At CNC Rapid, quality is a top priority. We conduct inspections throughout the production process, from the first article to the final batch. Every mounting seat undergoes thorough checks to verify:

- Flatness of the mounting surfaces

- Accuracy of the drilled and tapped holes

- Consistency of dimensions across multiple parts

This commitment to precision means our clients receive parts that are ready to use and built to last.

Applications Across Industries

Our custom steel mounting seats are used in multiple industries worldwide, including:

- Manufacturing – Supporting CNC machines, automation systems, and assembly lines.

- Electronics – Providing stable platforms for sensitive equipment.

- Energy – Serving as support structures for pumps, motors, and generators.

- Construction – Acting as durable mounting points in structural systems.

By customizing dimensions, finishes, and mounting features, we help clients achieve the perfect solution for their application.

Why Partner with CNC Rapid?

- Expertise in CNC machining – Years of experience in producing precision steel and aluminum parts.

- Custom solutions – Tailored designs to meet exact customer specifications.

- Consistent quality – Advanced inspection and quality assurance at every stage.

- Reliable delivery – Fast turnaround for both prototypes and production runs.

Our global clients from Europe, America, and Australia trust CNC Rapid as their machining partner because we consistently provide high-quality results.

Contact CNC Rapid Today

If you need a custom CNC machined steel mounting seat or other precision components, CNC Rapid is ready to help. From prototypes to high-volume production, we deliver reliable machining solutions that meet the highest standards of accuracy and durability.

Get in touch with us today to discuss your project requirements and see how our expertise can bring your ideas to life.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!