CNC Turning Service

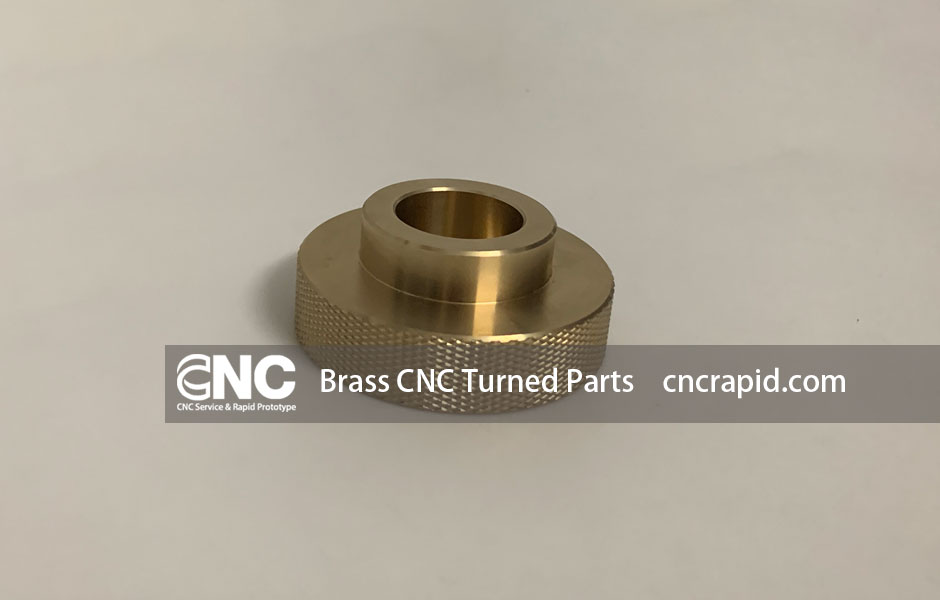

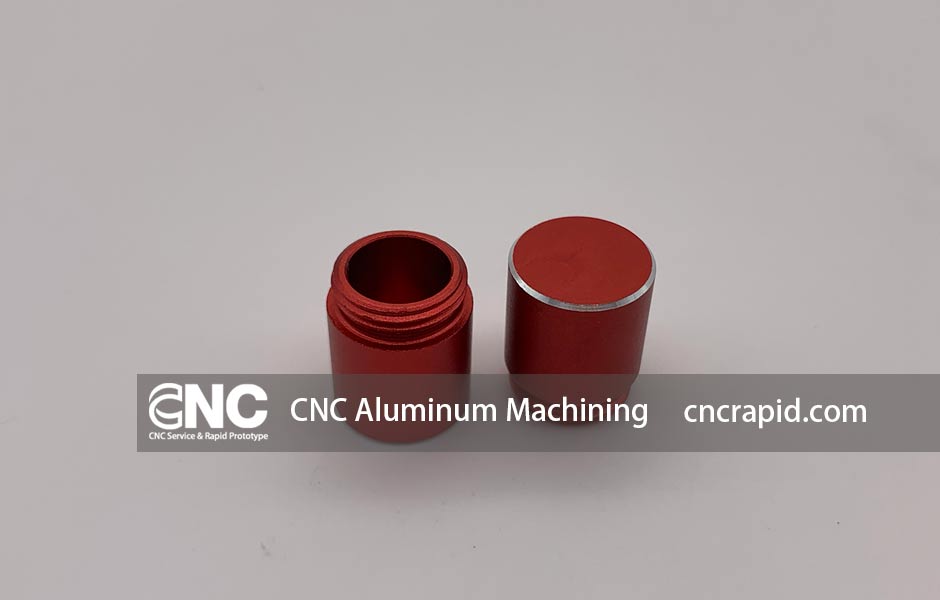

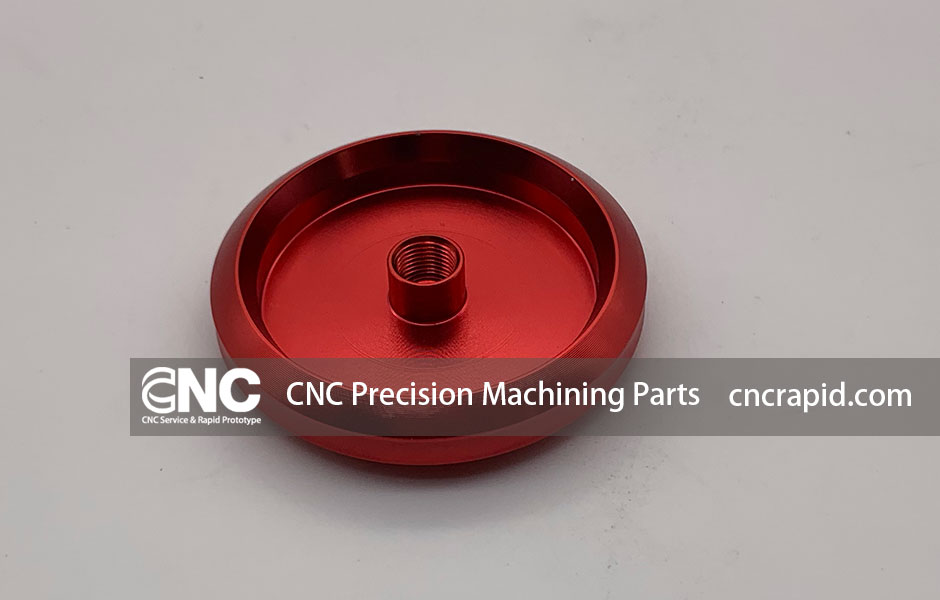

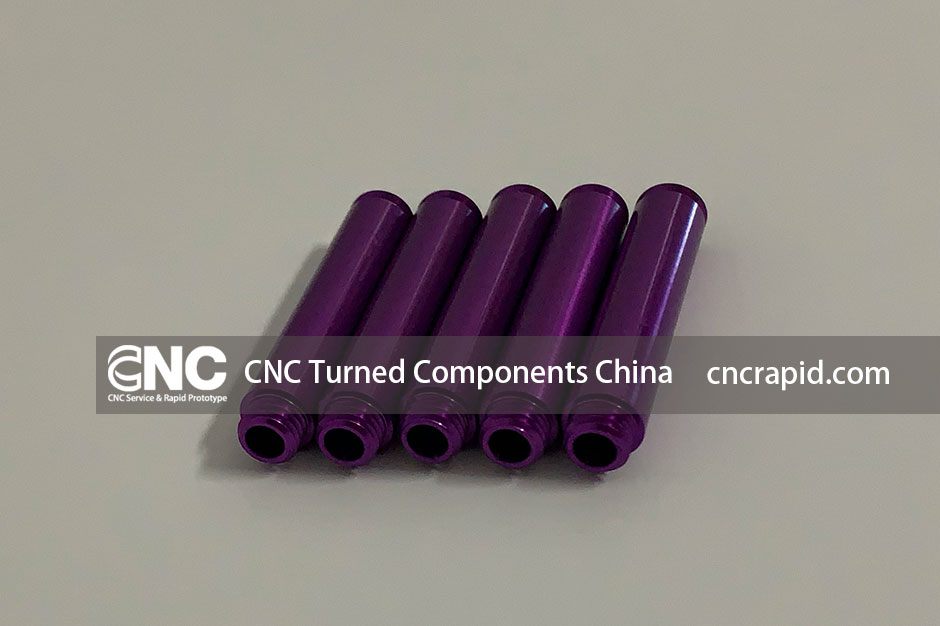

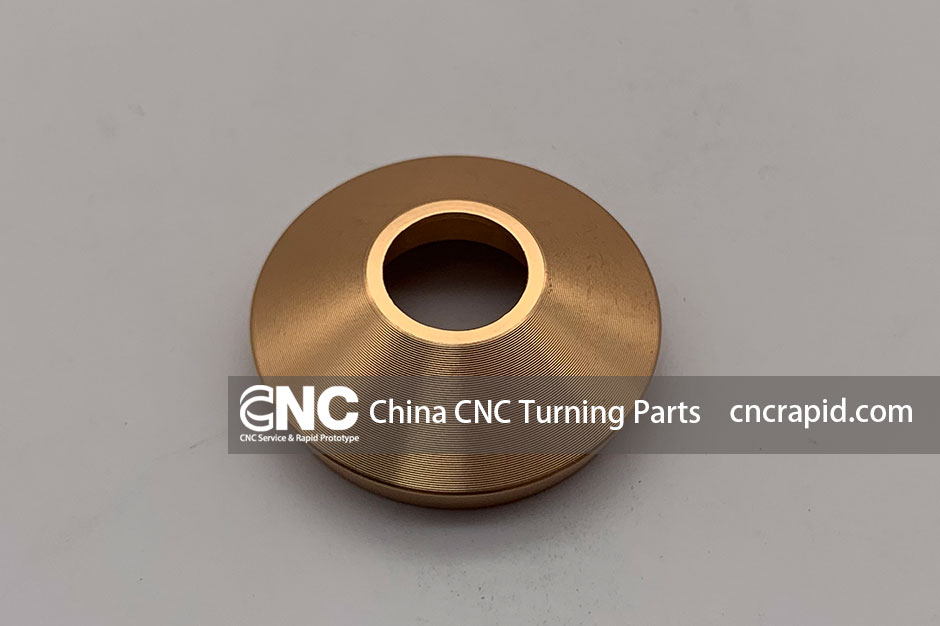

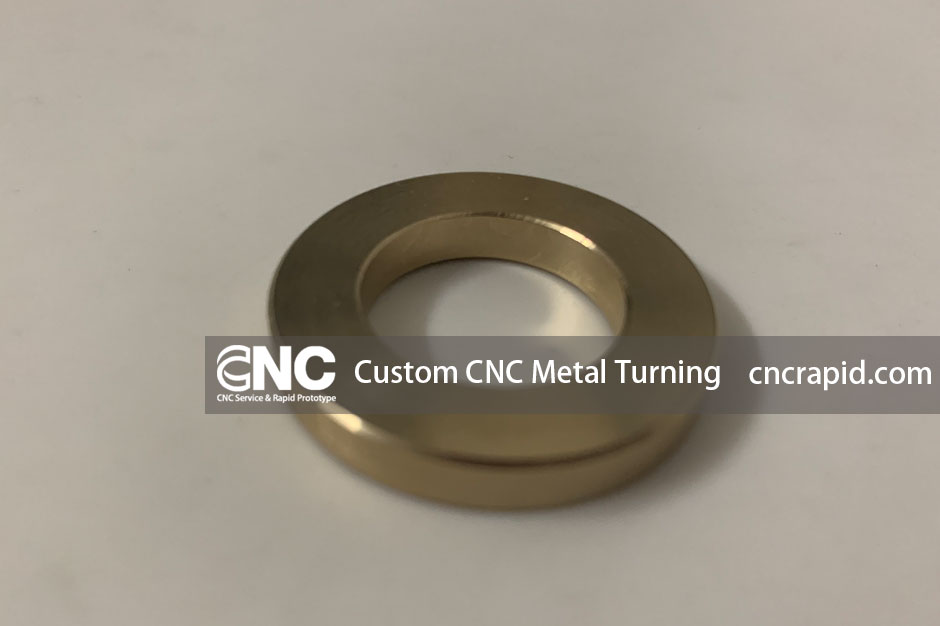

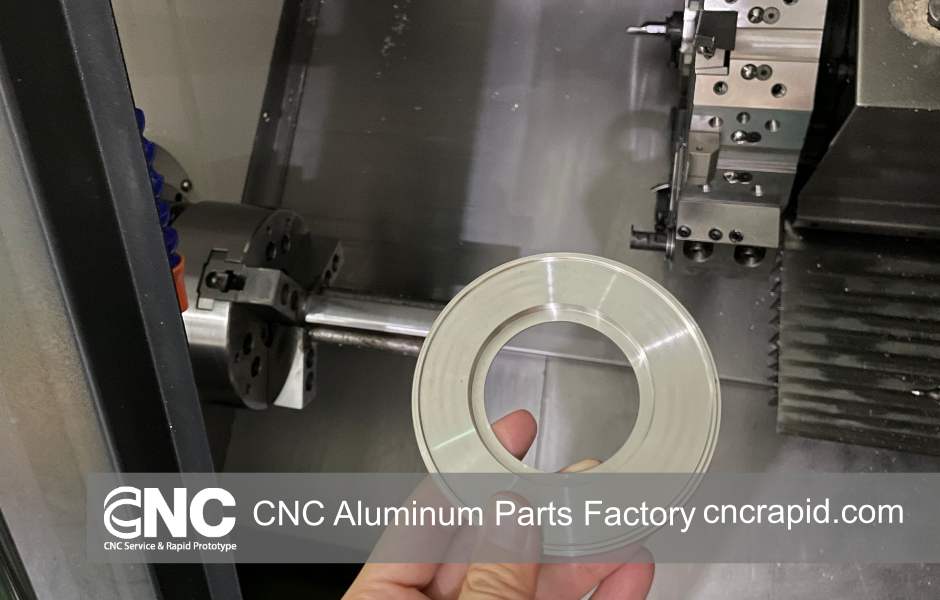

We specialize in machining Stainless Steel, Aluminum, and Brass, as well as plastics like Acetal (Delrin/POM), Nylon, and PEEK. Upload your CAD files to receive a prompt CNC turning quote.

Our CNC turning service capabilities

From prototyping to full production runs. Our wide range of CNC lathes and turning centers will allow you to produce highly accurate, high quality parts to meet even your most stringent requirements.

CNC lathe

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

Available materials for CNC machining at DFM Rapid

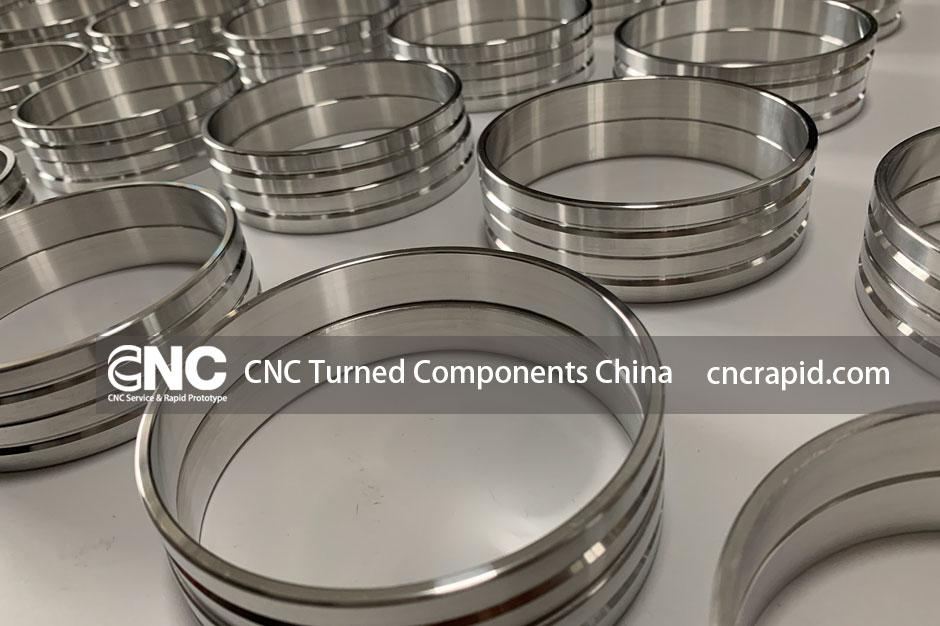

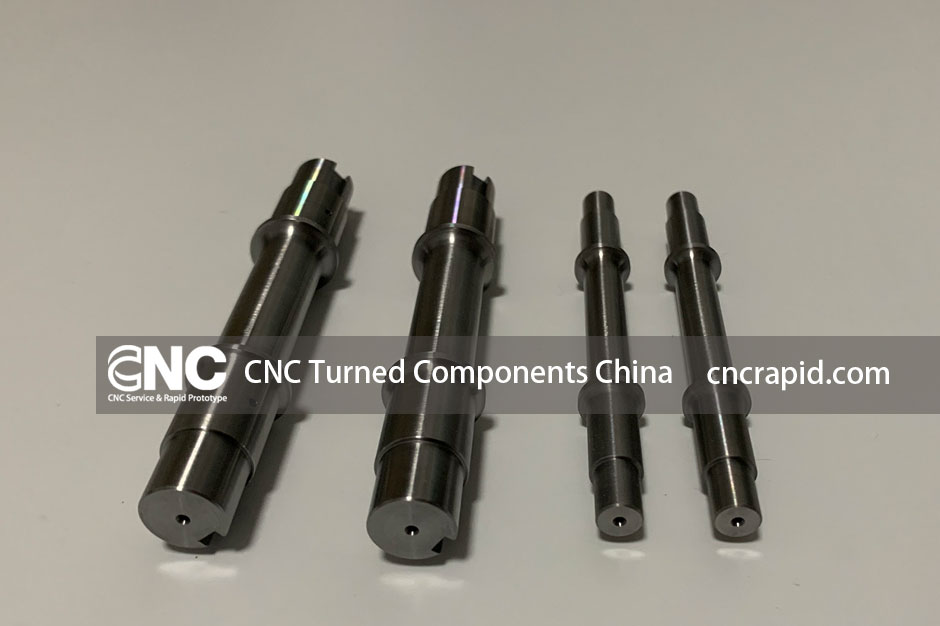

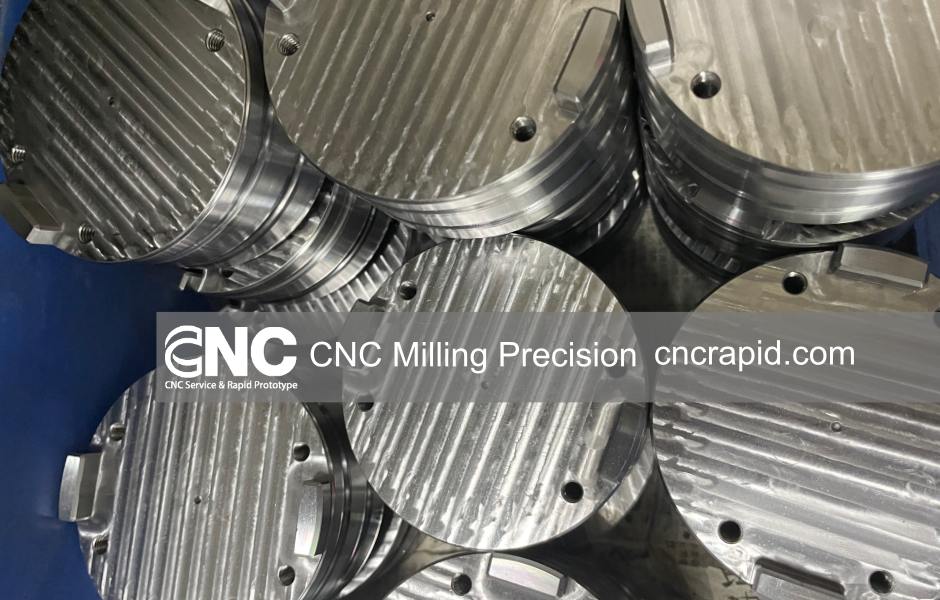

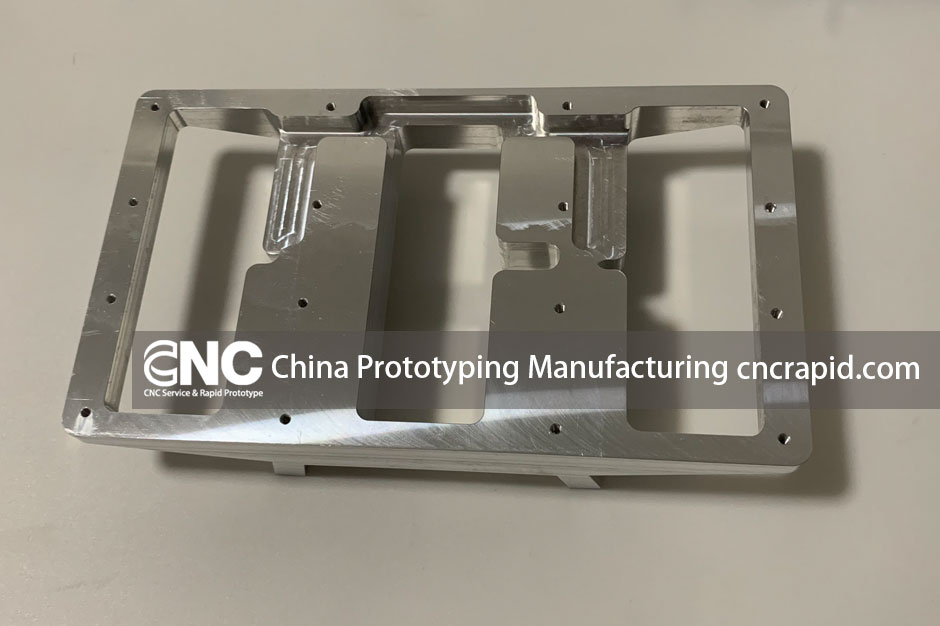

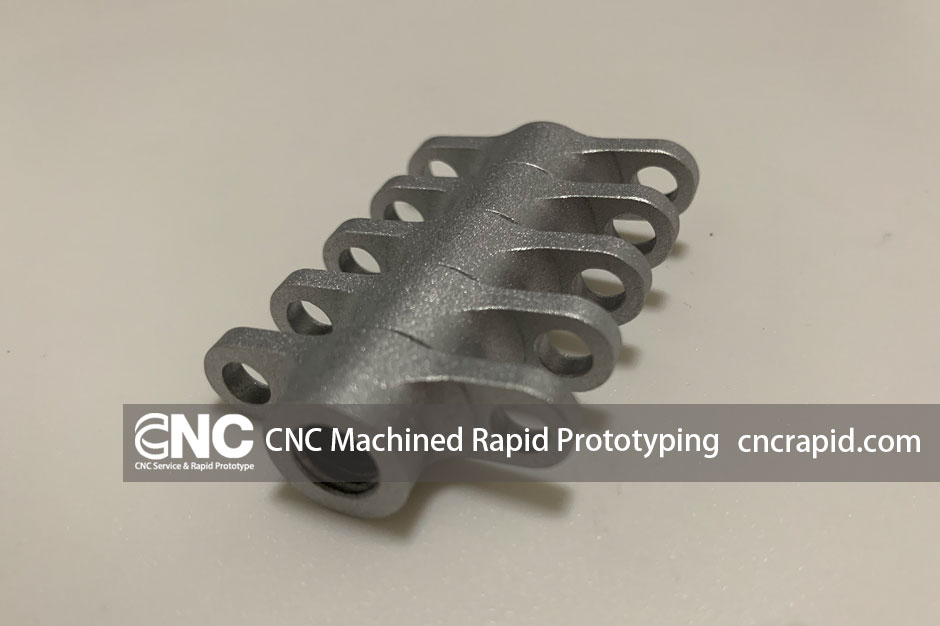

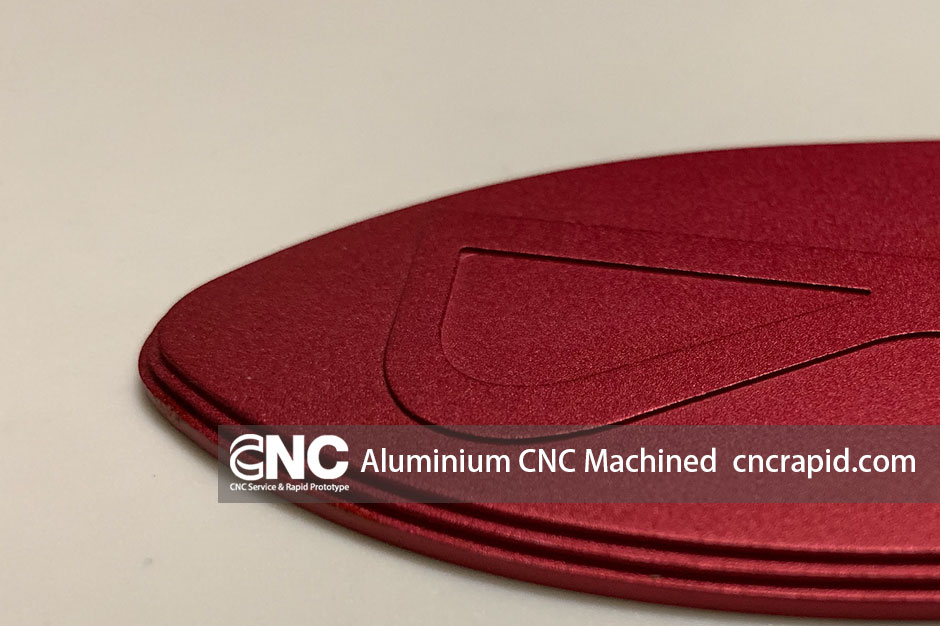

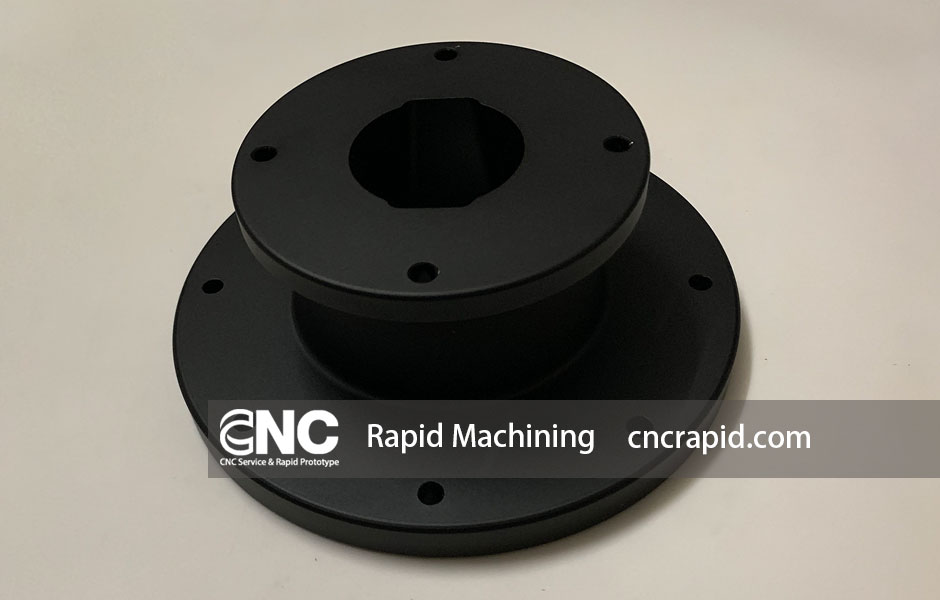

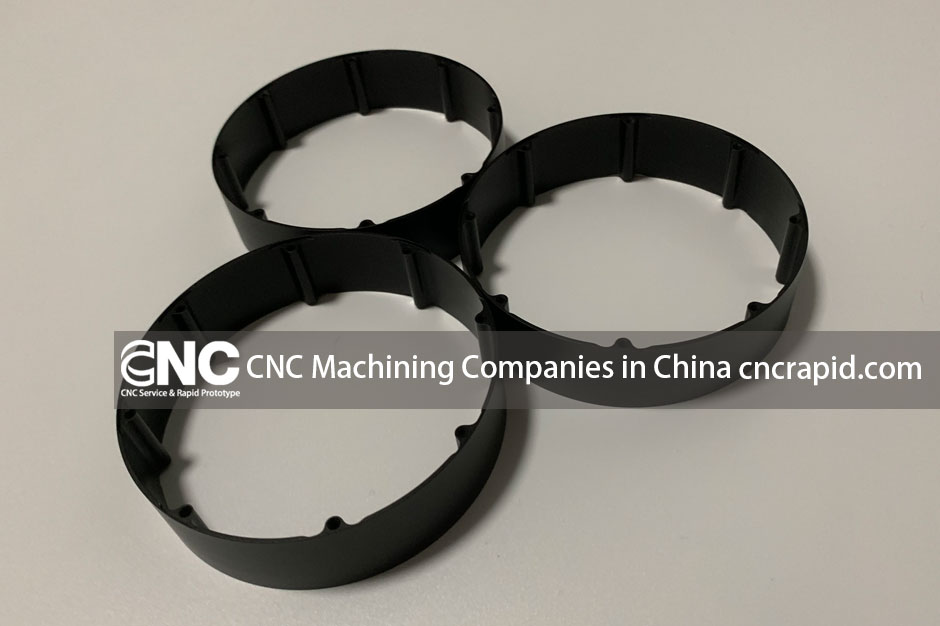

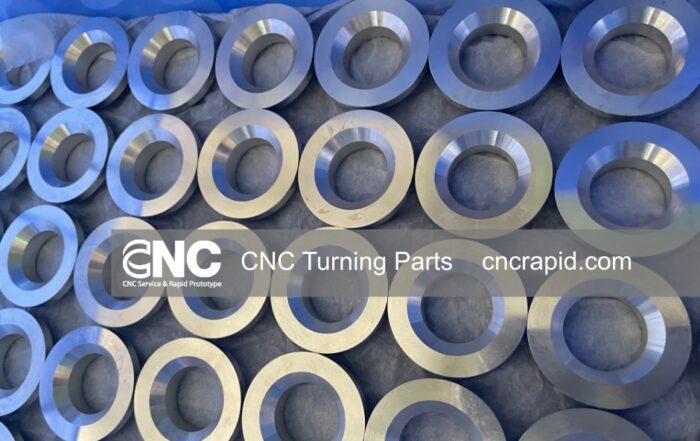

Gallery of CNC machined parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Available surface finishes for CNC machining

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

This is our standard finish. Parts are machined and deburred, sharp edges are chamfered.

Smooth machining is like an ‘As machined’ finish but with slightly less evident machine marks. Parts are machined at a lower feed, no hand polishing is applied.

Parts are bead blasted and anodized type II. Ideal for increasing the corrosion resistance of the part. Results in naturally matte colors.

Parts are bead blasted and an anodizing type III coating is directly applied to the surface. Ideal to improve corrosion and wear resistance of components.

Parts are brushed and then anodized type II. Ideal for increasing the corrosion resistance of the part. Typically results in a glossy color.

Powder coating is a strong, wear-resistant finish that is compatible with all metal materials.

Applicable to numerous substrates, black chrome plating is an electrochemical procedure that enhances wear resistance and provides a distinguished, dark aesthetic.

Tolerances

We follow ISO 2768-f standards for CNC Machining. Our standard tolerances are 0.1 mm(.005”), which is suitable for the majority of commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

Black Anodized CNC Machined Shaft – Custom Turning Service

At CNC Rapid, we specialize in producing high-quality CNC Machined Shaft that meet the strict requirements of engineers, designers, and manufacturers around the world. One of our recent projects showcases a custom aluminum shaft, manufactured [...]

CNC Turn-Mill Machining: Custom Plastic and Steel Parts by CNC Rapid

At CNC Rapid, we pride ourselves on pushing the boundaries of precision and efficiency in custom part manufacturing. Our latest advancements in CNC turn-mill machining allow us to produce high-quality custom parts from a variety [...]

Your Trusted CNC Turned Parts Manufacturer for Custom Prototypes

Precision CNC turned parts are crucial for industries requiring high accuracy and fine details in cylindrical components. As a leading CNC turned parts manufacturer, CNC Rapid combines technical expertise with advanced machinery to produce top-quality [...]

CNC Rapid: Your CNC Turning Manufacturing Partner

CNC turning is a manufacturing process where a rod of material is rotated while a cutting tool shapes it to create cylindrical parts with precise dimensions. This process is favored for its numerous benefits, which [...]

Why CNC Rapid is the Best for CNC Turning Parts

Before diving into the prowess of CNC Rapid, it's essential to understand the basics. CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool [...]

Why Choose CNC Rapid as Your Custom CNC Turning Parts Supplier?

CNC Rapid is a leading supplier of custom CNC turning parts. We have a team of experienced machinists and engineers who can help you with all of your CNC turning needs. We can machine parts [...]