Brushed + Anodized type II

Parts are brushed and then anodized type II. Ideal for increasing the corrosion resistance of the part. Typically results in a glossy color. The “Brushed + Anodized Type II” surface finish emerges as a stellar choice, offering a blend of visual appeal and robust protection.

The Art of Brushing

- Process: Utilizing abrasive materials, brushing creates a unidirectional satin finish, reducing surface imperfections and providing a consistent grain.

- Aesthetics: The linear fine lines offer a refined appearance, often utilized to obscure fingerprints and light scratches.

- Applications: Widely adopted in decorative pieces, automotive components, and consumer electronics for its subtle elegance.

The Science Behind Anodizing Type II

- Process: An electrochemical procedure that forms a controlled oxide layer, enhancing corrosion resistance and wear properties.

- Color Customization: Allows for dyeing, offering a spectrum of color options for aesthetic and identification purposes.

- Applications: Predominantly used in aerospace, automotive, and consumer goods for its durability and visual versatility.

A Harmonious Fusion: Brushed + Anodized Type II

- Combined Benefits: The amalgamation of brushing and anodizing provides a surface that is not only visually striking but also functionally durable.

- Versatility: Suitable for a myriad of applications where both appearance and resilience are requisite.

- Sustainability: The anodizing process is environmentally friendly, producing non-toxic by-products.

Applications in CNC Machining

- Consumer Electronics: For components requiring a blend of aesthetic sophistication and resistance to wear.

- Automotive: In interior and exterior parts, where visual appeal and durability are paramount.

- Architectural: Utilized in structures demanding a visually pleasing yet corrosion-resistant surface.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

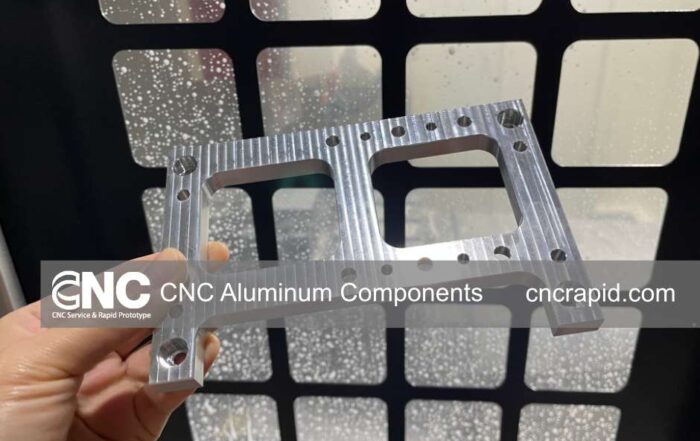

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

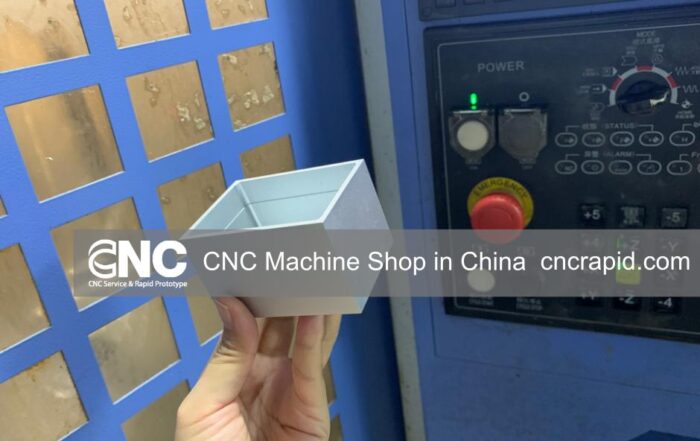

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]