At CNC Rapid, we understand the critical nature of medical device manufacturing. Our advanced CNC machining services are at the forefront of bringing innovative medical devices from concept to reality, ensuring every product or parts meets the highest standards of quality and precision.

The Importance of CNC Machining in Medical Device Manufacturing:

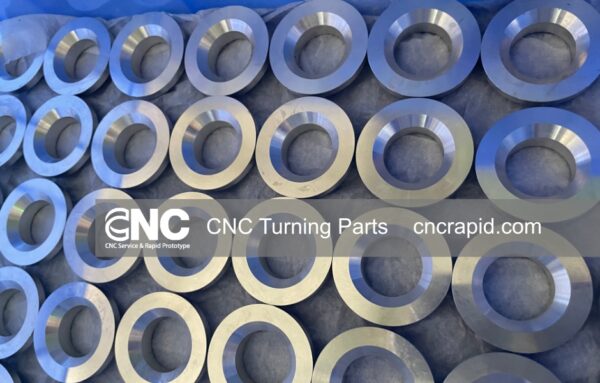

CNC machining is a cornerstone in the medical device manufacturing industry, offering high precision, repeatability, and efficiency. This technology allows for the production of complex parts with tight tolerances that are essential for medical devices. From prototypes to large-scale production, CNC machining’s versatility makes it indispensable for medical technology’s advancements.

CNC Rapid’s Expertise:

At CNC Rapid, our expertise in CNC machining spans decades, positioning us as a leader in the production of high-quality medical devices parts. Our team of skilled engineers and machinists utilizes the latest in CNC technology to deliver products that exceed industry standards. With a deep understanding of the medical industry’s requirements, we ensure that every device we produce is not only precise but also compatible with the stringent regulations of medical technology.

Our Capabilities:

Our facility is equipped with advanced CNC machinery capable of handling a wide range of materials, including titanium, stainless steel, plastics, and more, ensuring we can meet the diverse needs of the medical device sector. We offer a comprehensive suite of services from 3D CAD modeling and prototyping to final production, all under one roof. This integrated approach not only speeds up the manufacturing process but also maintains the integrity and quality of the final product.

Why Choose CNC Rapid for Your Medical Device Manufacturing Needs:

- Precision and Quality: Our commitment to precision and quality is unmatched, ensuring every part meets your exact specifications.

- Speed and Efficiency: With advanced machinery and expert staff, we can turn around projects quickly without compromising quality, helping you get your products to market faster.

- Regulatory Compliance: We understand the regulatory requirements of the medical device industry and ensure that all products are compliant with necessary standards.

- Customer-Centric Approach: At CNC Rapid, we work closely with our clients to understand their needs and provide customized solutions that meet their unique challenges.

CNC Rapid is ready to bring your medical device concepts to life with precision, efficiency, and quality at the forefront of everything we do. Let us help you navigate the complexities of medical device manufacturing, ensuring your products not only meet but exceed the expectations of the medical community and the patients they serve.

Contact CNC Rapid Today!

Ready to start your next project? Contact CNC Rapid today to see how our CNC machining services can accelerate the development and production of your medical devices. Experience the difference that precision and expertise can make.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!