Precision Engineering for Health Innovations

At CNC Rapid, we specialize in producing high-precision CNC parts for the rapidly evolving medical devices sector. Our advanced CNC milling centers, including 3 axis, 4 axis, and 5 axis machines, enable us to manufacture parts with exceptional accuracy, catering to the stringent requirements of medical innovations.

Why Choose CNC Rapid for Medical Device Parts?

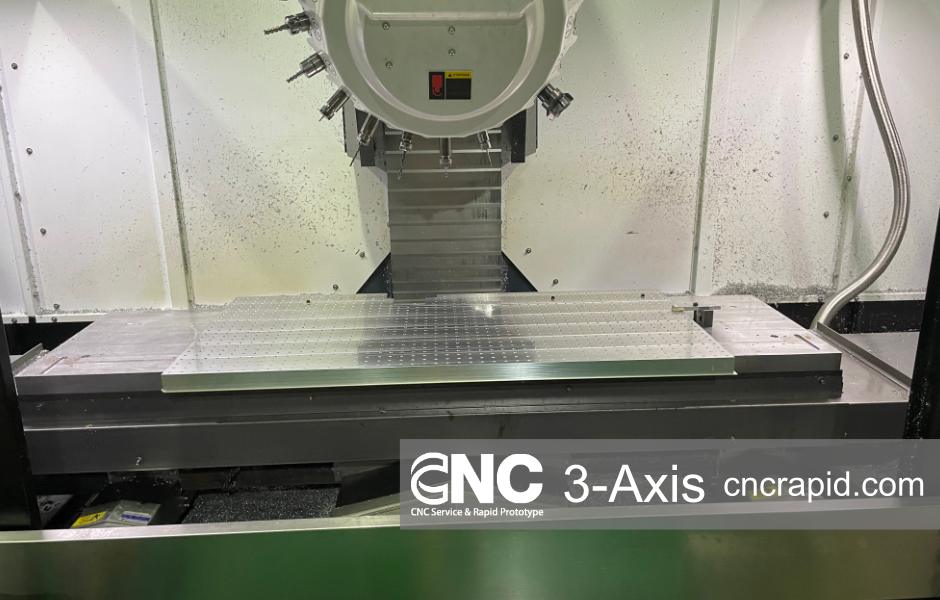

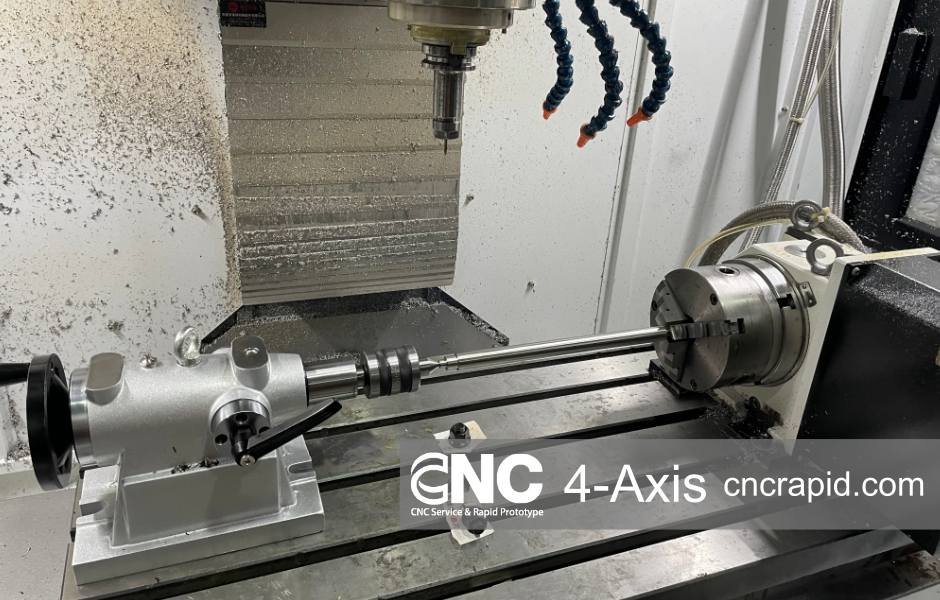

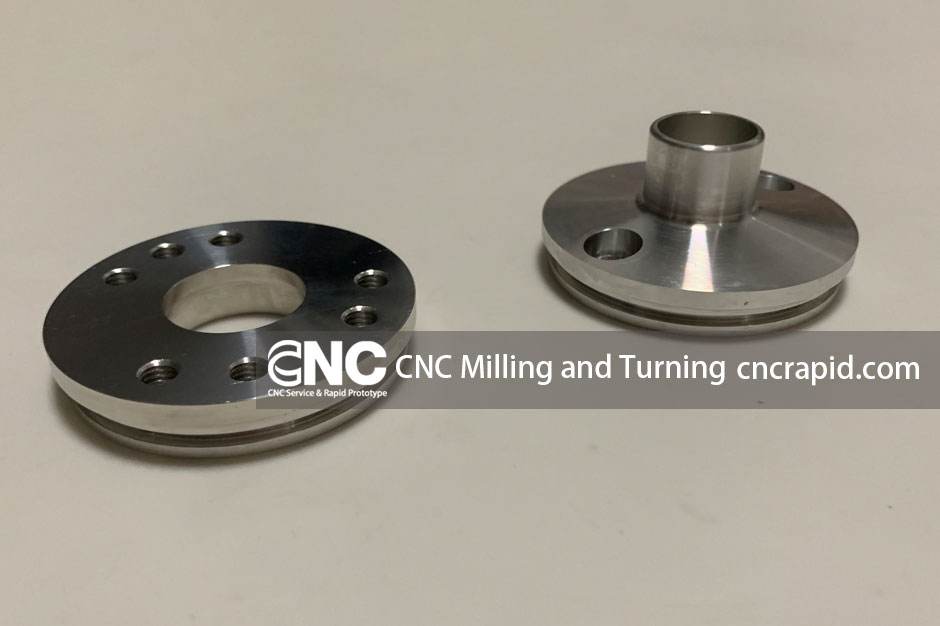

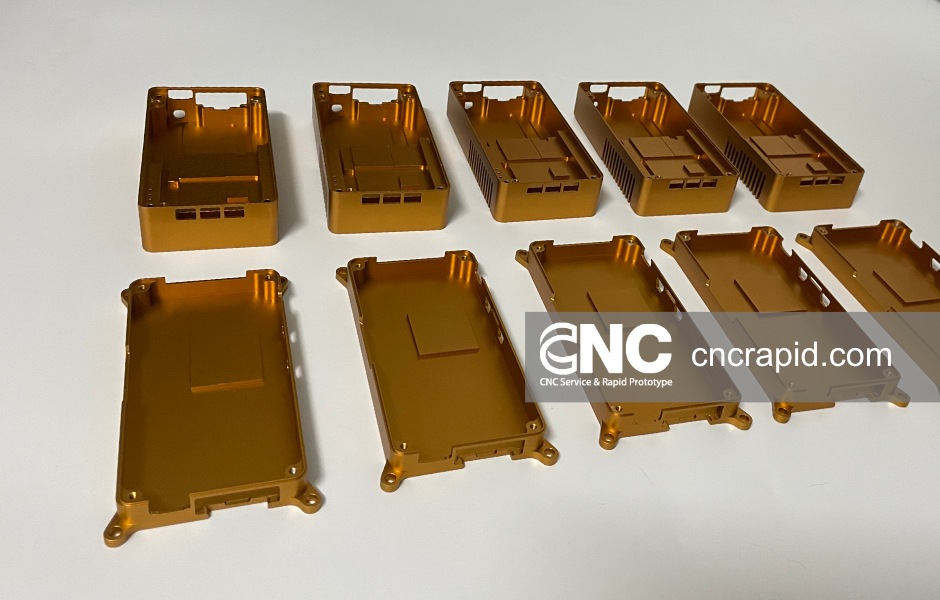

Our 3 Axis CNC mills, widely used in the industry, offer versatile machining options with the full use of X, Y, and Z directions. For more complex designs, our 4 Axis routers allow continuous machining with a vertical axis rotation, while our 5 Axis CNC milling efficiently handles parts with intricate geometries. We apply various surface finishes that enhance appearance, surface roughness, hardness, and chemical resistance – vital for medical device components. Adhering to ISO 2768-f standards, our standard tolerances are +/-0.1 mm, suitable for most commercial and medical applications. We also offer closer tolerances for specialized projects.

Rapid Prototyping and Production

We provide rapid prototyping and low-volume production, essential for the fast-paced development of medical devices. This capability allows for quick iteration and testing of parts, speeding up the innovation process.

Medical Devices manufacturing capabilities

Materials & surface finishes for Medical Devices

Materials for medical devices

Steel & stainless steel: 304/304L, 316/316L, 17-4H

Titanium: Ti grade 1, 2, 5

Aluminum: 6061-T6, 7075-T6, 5083-H111, 2024-T351

Brass & copper alloys: C360, copper C110, copper C101

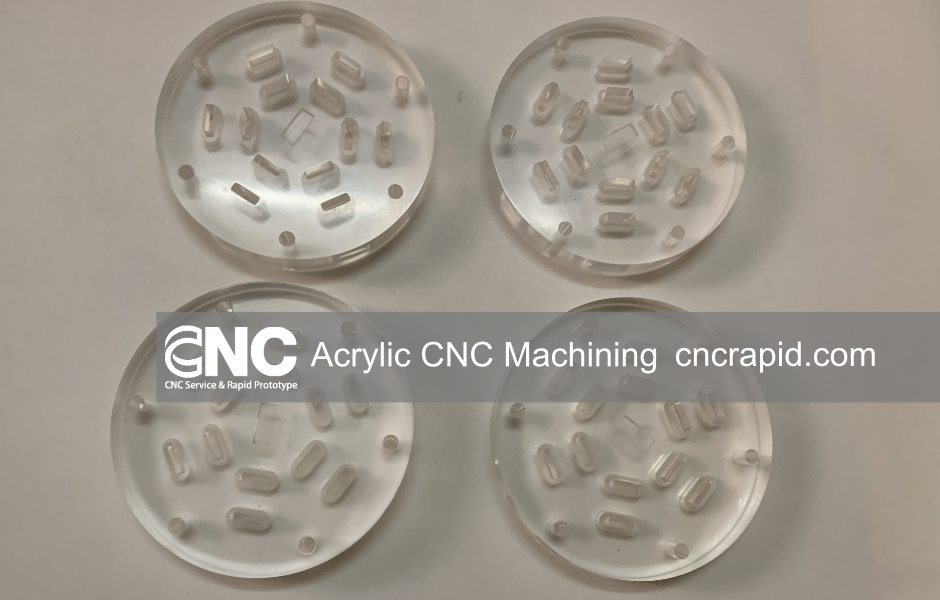

Thermoplastics: Polycarbonate (PC), ABS M30i, PLA, PEEK, Ultem 1010, PA 12

Commodity polymers: Polyethylene (PE), Polypropylene (PP), PVC

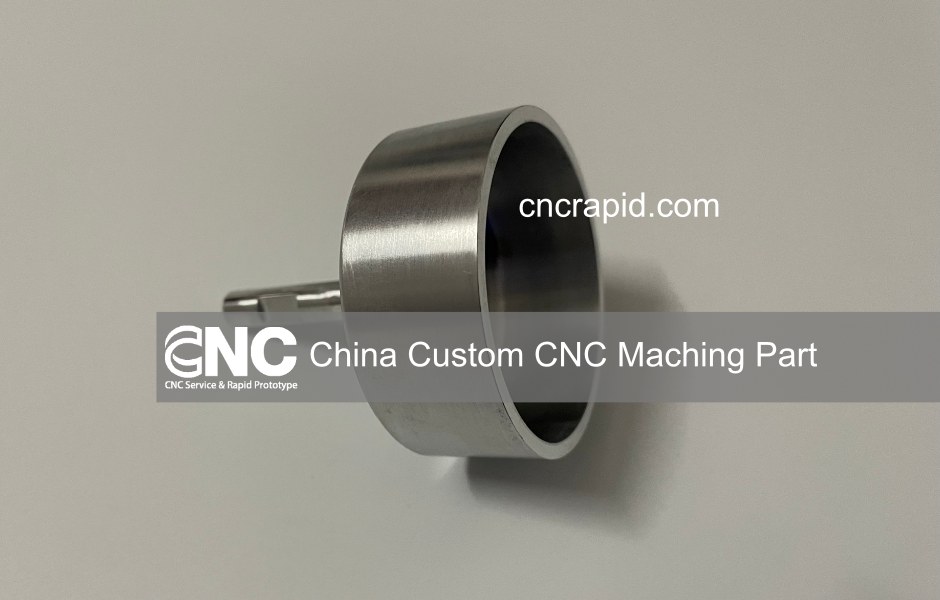

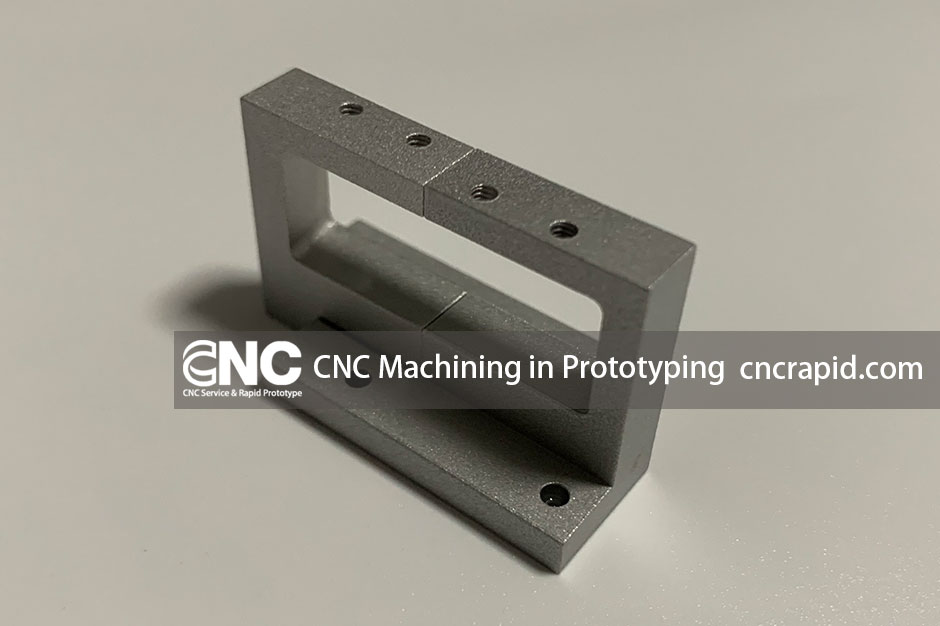

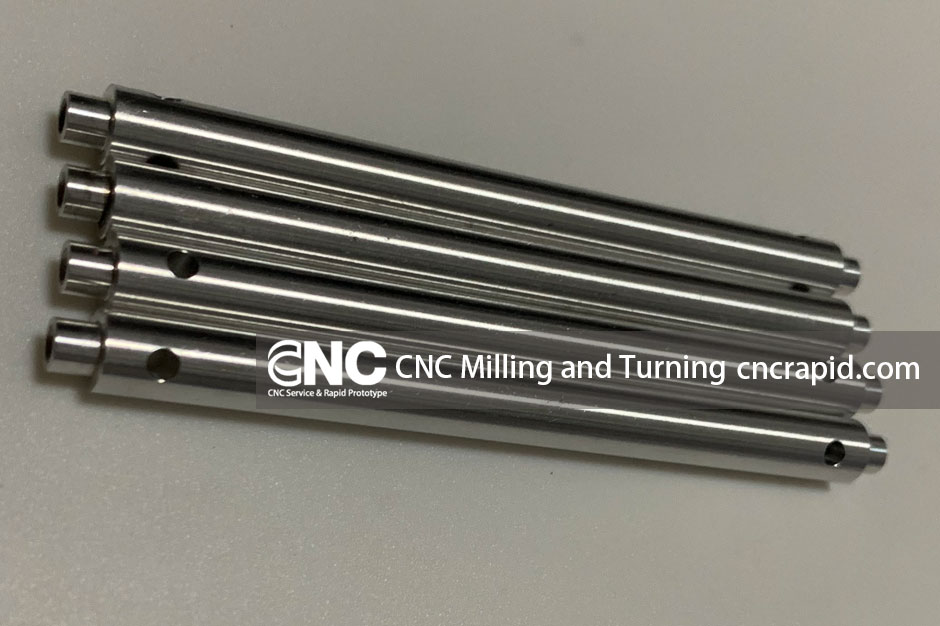

Gallery of CNC machined Medical Devices parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Contact CNC Rapid Today!

Our expertise isn’t limited to medical devices; we also serve industries like aerospace, automotive, electronics, and more. This broad experience informs our approach to creating medical device parts that meet diverse and complex needs.

About DFM Rapid

At CNC Rapid, we are more than just a machining service. We are partners in your quest for health innovation, offering precision, speed, and reliability in manufacturing the critical components that power medical breakthroughs. Whether it’s a prototype or a full-scale production run, our team is equipped to bring your medical device concepts to life.