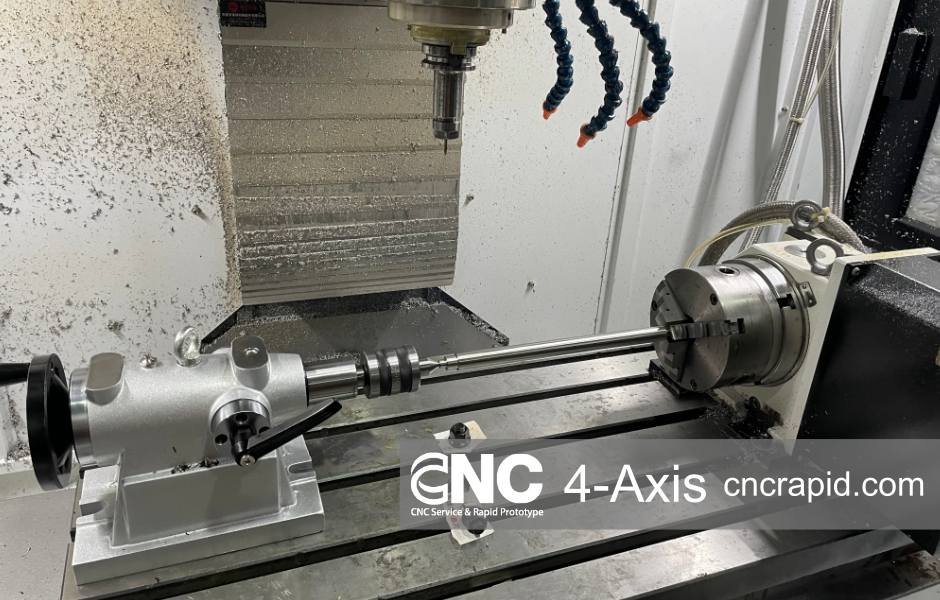

The Role of 4-Axis CNC in Production

4-Axis CNC machining stands at the intersection of innovation and efficiency. For engineers striving for perfection and business leaders eyeing operational excellence, it’s a technology that warrants attention. As the manufacturing world continues to evolve, those equipped with the knowledge and capabilities of 4-Axis CNC will undoubtedly lead the way.

The quest for greater precision and efficiency is paramount in manufacturing. 4-Axis CNC machining—a game-changer—is reshaping the contours of modern production. For engineers and business leaders alike, understanding this technology is crucial. Let’s delve into its intricacies.

The Essence of 4-Axis CNC Machining: At its core, 4-Axis CNC machining is an extension of the traditional 3-Axis system. While the 3-Axis system operates on the X, Y, and Z planes, the 4-Axis introduces an additional rotational axis, often referred to as the A-axis, which rotates around the X-axis. This added dimension allows for more complex and precise operations without the need for multiple setups.

Key Advantages:

- Enhanced Geometrical Capabilities: Produce more intricate parts with undercuts, side operations, and complex geometries without repositioning.

- Streamlined Production: Reduced setup times translate to faster production cycles and cost savings.

- Superior Surface Finishes: Continuous rotation ensures smoother finishes, especially for round or cylindrical parts.

Applications in Modern Engineering: From aerospace turbine components to intricate automotive parts, 4-Axis CNC machining is making its mark. Its ability to produce parts with tight tolerances and complex geometries makes it indispensable in industries demanding high precision.

Business Implications: For enterprise leaders, investing in 4-Axis CNC technology can lead to significant ROI. The efficiency gains, coupled with the ability to produce high-value parts, can provide a competitive edge in the market. Moreover, as industries move towards more complex product designs, having 4-Axis capabilities will become increasingly essential.

Challenges and Considerations: While 4-Axis CNC machining offers numerous advantages, it’s essential to consider the learning curve associated with programming and operation. Ensuring that operators receive adequate training and have access to advanced CAM software is vital.

The Future of 4-Axis CNC: As we look ahead, the integration of AI and IoT with 4-Axis CNC machines promises even greater precision and automation. Real-time data analytics can further optimize operations, paving the way for smart manufacturing.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

What is CNC Machining Rapid Prototyping?

At CNC Rapid, we adapt our rapid prototyping services to meet the unique needs of each client. With the ability to work from customer-supplied designs and drawings, we transform your conceptual ideas into high-fidelity prototypes [...]

Custom CNC Aluminum vs. Other Materials: What Sets It Apart?

Manufacturing materials play a pivotal role in determining the quality, durability, and functionality of the final product. Among the plethora of materials available, aluminum, especially when processed through CNC machining, has emerged as a favorite [...]

Applications of CNC Machining You Didn’t Know About

CNC Rapid is leading the way in changing industries by making things with very accurate engineering. CNC machining, a process used in the manufacturing sector, involves the use of computers to control machine tools. While [...]

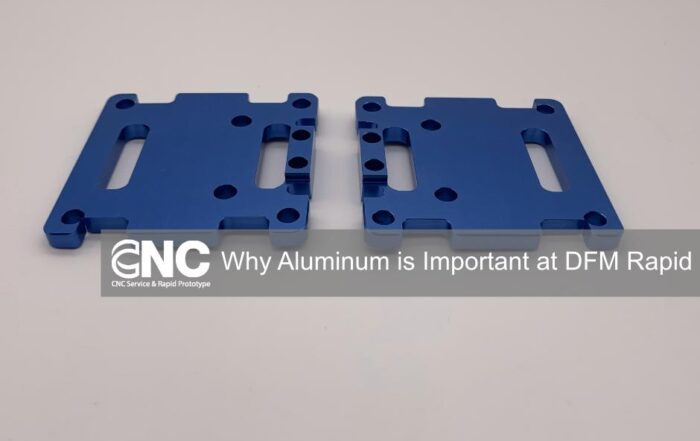

Why Aluminum is the Go-To Material for CNC Machining at CNC Rapid

In the dynamic world of CNC machining, one material consistently stands out: aluminum. Here at DFM Rapid, also known as CNC Rapid, we've mastered the art of using this versatile metal to deliver superior, precision-engineered [...]

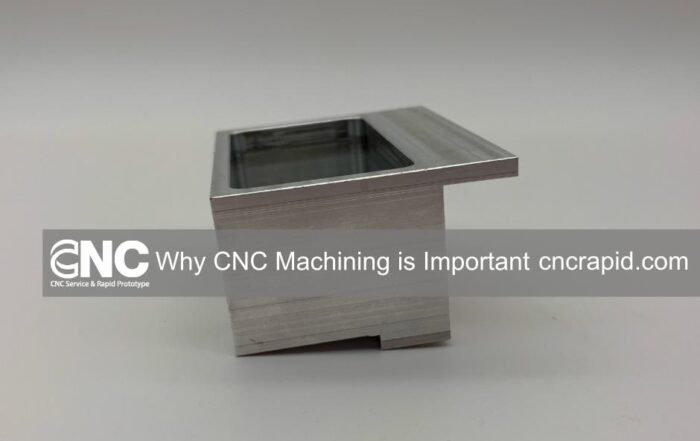

The Importance of CNC Machining in Modern Manufacturing

CNC machining has revolutionized the manufacturing industry. This manufacturing process, where pre-programmed computer software dictates the movement of machinery and factory tools, has automated three-dimensional cutting tasks in a precise and efficient manner. At DFM [...]

Can CNC machines produce custom parts with different surface finishes?

Custom parts are parts or components that are designed and produced to meet specific requirements or specifications. CNC machining is ideal for producing custom parts because it can accurately and precisely machine parts with unique [...]