Manufacturing materials play a pivotal role in determining the quality, durability, and functionality of the final product. Among the plethora of materials available, aluminum, especially when processed through CNC machining, has emerged as a favorite for many industries. But what makes custom CNC aluminum stand out from other materials? Let’s delve into the unique properties and advantages of custom CNC aluminum and see how it compares to its counterparts.

1. Lightweight Yet Strong

Aluminum is renowned for its lightweight properties. However, despite its lightness, it boasts impressive strength, especially when alloyed with other metals. This combination of strength and lightness makes it an ideal choice for industries like electronic equipment, automotive, and robotics, where weight considerations are paramount.

2. Excellent Thermal and Electrical Conductivity

Aluminum is a good conductor of both heat and electricity. This makes it a preferred choice for electronic housings, heat sinks, and other applications where efficient heat dissipation or electrical conductivity is required.

3. Corrosion Resistance

When exposed to air, aluminum forms a thin oxide layer that acts as a protective shield against corrosion. This natural resistance to rust and corrosion ensures that CNC machined aluminum parts remain durable and long-lasting, even in challenging environments.

4. Malleability and Ductility

Aluminum’s malleability allows it to be easily shaped into intricate designs without compromising its structural integrity. This property, combined with the precision of CNC machining, enables the creation of complex and detailed parts that might be challenging with other materials.

5. Cost-Effective

While aluminum might have a higher initial cost than some other materials, its durability, low maintenance requirements, and long lifespan often result in lower overall costs in the long run.

6. Aesthetic Appeal

With its natural shine and ability to take on various finishes, aluminum parts not only perform well but also look premium. Whether it’s a brushed, polished, or anodized finish, aluminum can be tailored to meet the aesthetic requirements of any project.

Comparison with Other Materials

- Steel: While steel is stronger and more durable than aluminum, it is also heavier. For applications where weight is a concern, aluminum often emerges as the winner. Additionally, steel is more prone to corrosion unless treated or alloyed with other metals.

- Titanium: Titanium is known for its exceptional strength-to-weight ratio and corrosion resistance. However, it’s more expensive than aluminum. While it’s used in industries like aerospace and medical implants due to its biocompatibility, aluminum is often preferred for general manufacturing due to its cost-effectiveness.

- Brass: Brass is an alloy of copper and zinc and is known for its machinability and corrosion resistance. While it offers a unique aesthetic and is used in decorative and electrical components, it doesn’t match aluminum in terms of strength or thermal conductivity.

- Plastics: Plastics are versatile and can be molded into various shapes. However, they lack the strength, thermal conductivity, and durability of aluminum. Over time, plastics can degrade, especially when exposed to UV rays or chemicals.

Choosing the right material for CNC machining is crucial, and aluminum, with its myriad benefits, often emerges as a top contender. At CNC Rapid, we understand the nuances of aluminum machining and are committed to delivering excellence every time. Get a quote now and experience the CNC Rapid difference.

Why Choose CNC Rapid for Your Aluminum Machining Needs?

At CNC Rapid, we pride ourselves on delivering top-notch CNC machining services. Our commitment to quality, precision, and customer satisfaction has made us a preferred choice for many businesses. Whether you’re looking for a prototype or production, our team is equipped to handle projects of any scale.

- Expertise: Our articles, such as “Why CNC Machining Quotes Can Be Different” and “Why CNC Rapid is the Best for CNC Turning Parts,” showcase our deep understanding of the industry.

- Precision: With advanced machinery and a team of skilled professionals, we ensure every part is crafted to perfection.

- Quick Turnaround: Our efficient processes and expertise in aluminum machining mean faster delivery times for our clients.

At CNC Rapid, we understand that every project has unique requirements. Our diverse range of services ensures that we can cater to any need, be it a specific material, a particular machining process, or a custom part. Here’s a closer look at what we offer:

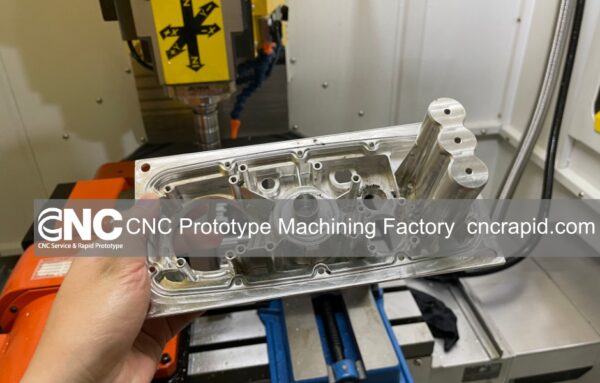

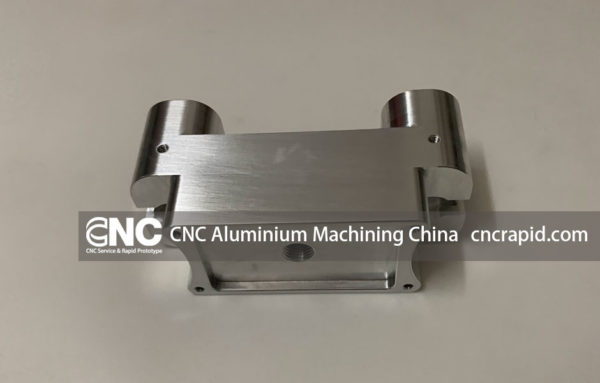

CNC Aluminium Machining

Harness the benefits of aluminum’s lightweight and durable properties with our specialized CNC aluminum machining services. We ensure precision and quality, making your parts ready for any application.

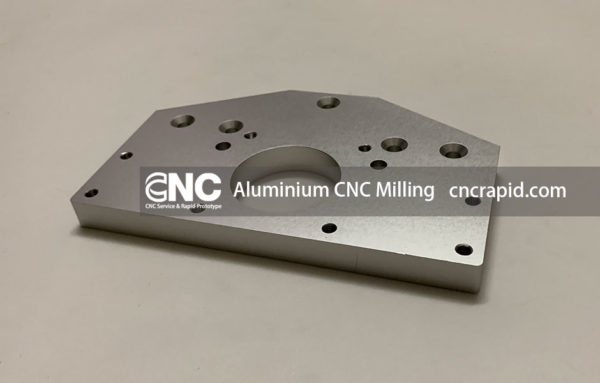

Aluminium CNC Milling

Our advanced milling machines are tailored for aluminum, ensuring intricate designs and high precision. Whether it’s a simple or complex part, our aluminum CNC milling service guarantees perfection.

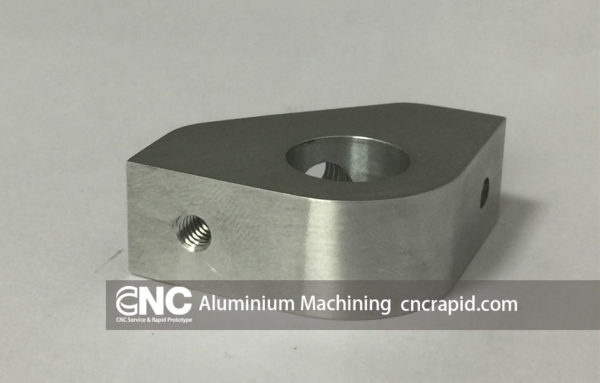

Aluminium Machining

Beyond CNC, our expertise extends to general aluminum machining. We handle various aluminum grades, ensuring the right match for your project’s needs.

CNC Machined Part Manufacturer

As a leading CNC machined part manufacturer, we pride ourselves on our meticulous attention to detail and commitment to quality. Every part we produce undergoes rigorous quality checks to ensure it meets the highest standards.

CNC Machining Part Supplier

Not only do we manufacture, but we also supply CNC machined parts to businesses across various industries. Our vast inventory and quick turnaround times ensure you get the parts you need when you need them.

Custom CNC Machining Part

Every project is unique, and we understand the importance of customization. Our team collaborates closely with clients to understand their requirements and deliver custom CNC machined parts tailored to their specifications.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!