CNC Rapid

Steel/Stainless steel/Brass/Aluminium CNC Service

Upload your CAD files, get a CNC machining services price estimate promptly, get your custom CNC parts into production.

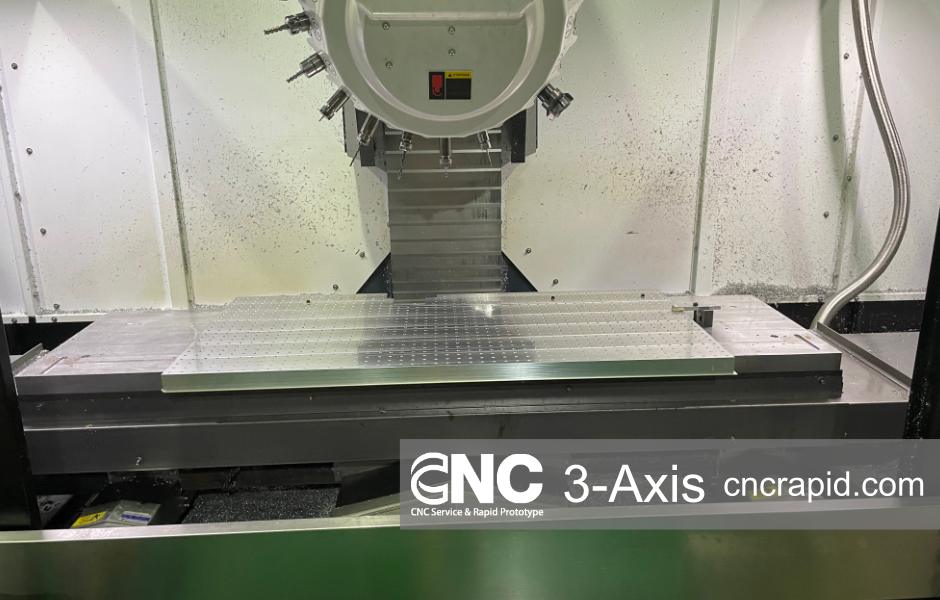

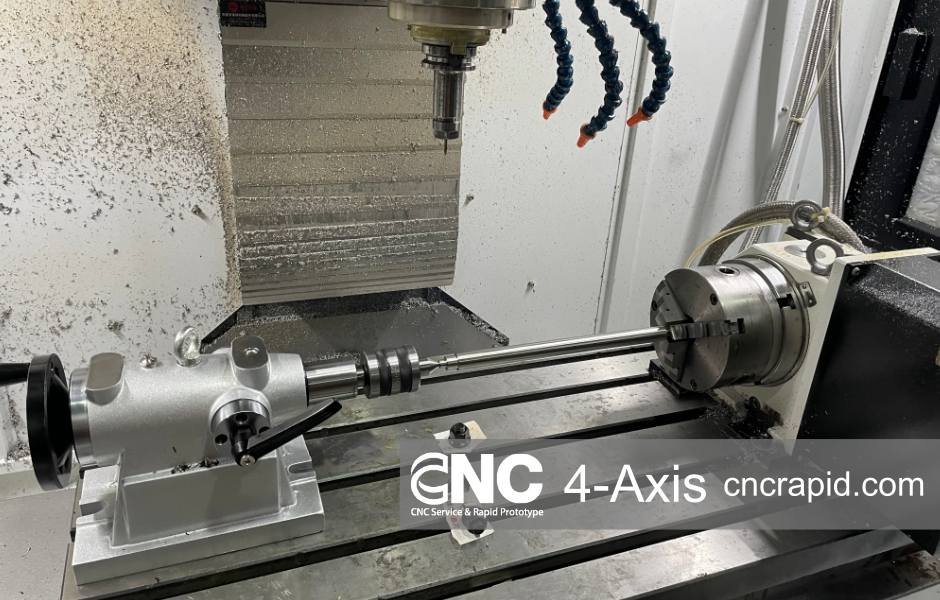

CNC Machining China: From prototyping to full production runs. Our 3 axis, 4 axis, and 3+2 axis CNC milling centers will allow you to produce highly accurate and quality parts to meet even your most stringent requirements.

Maximum part size for 3-axis, 4-axis and 3+2-axis CNC milling is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

Available materials for CNC machining at DFM Rapid

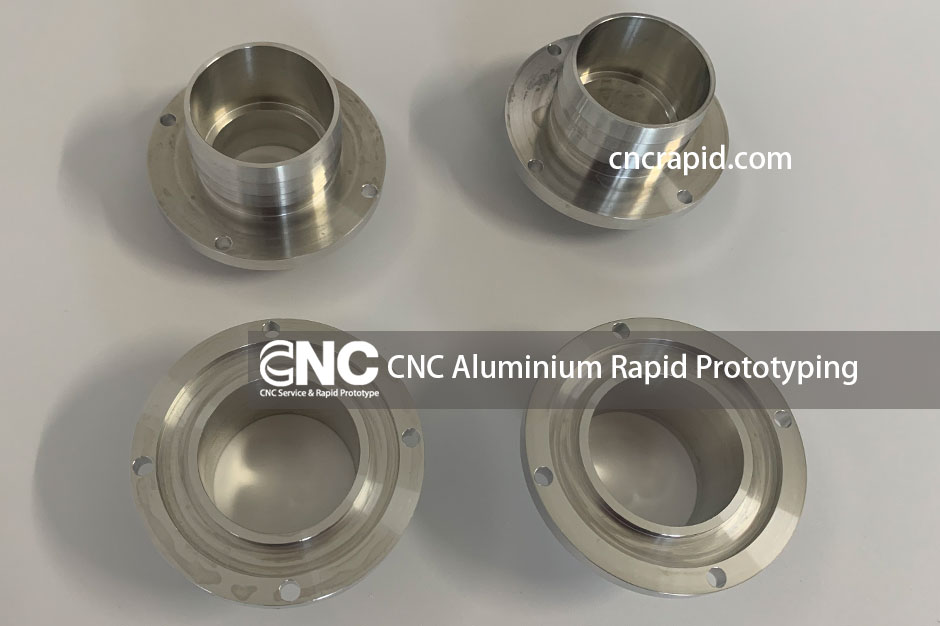

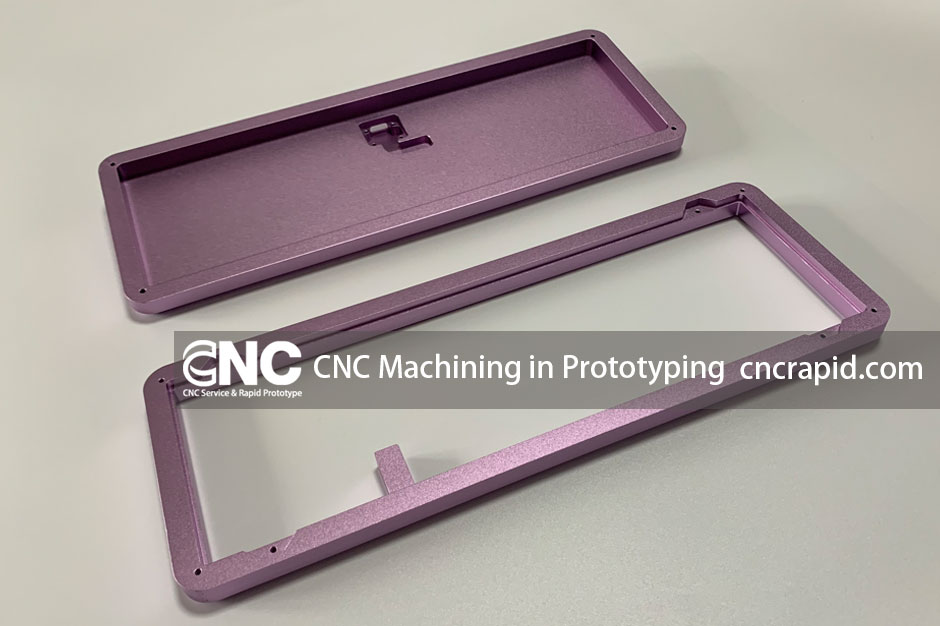

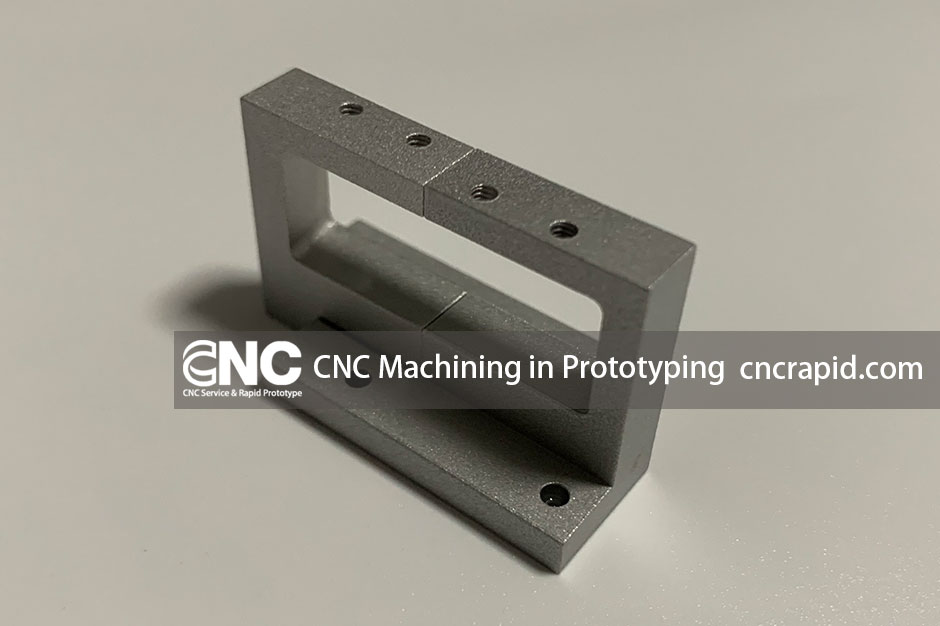

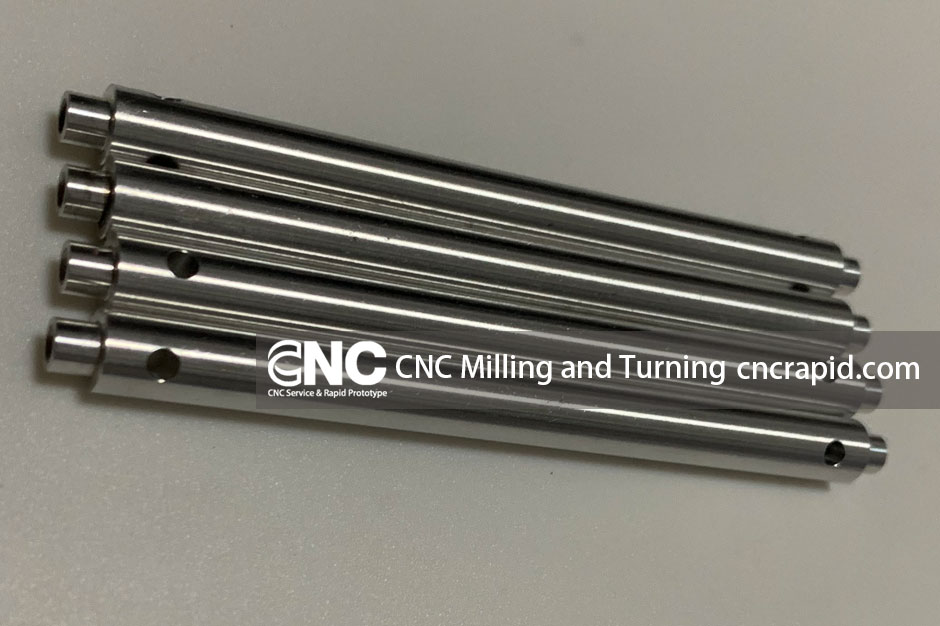

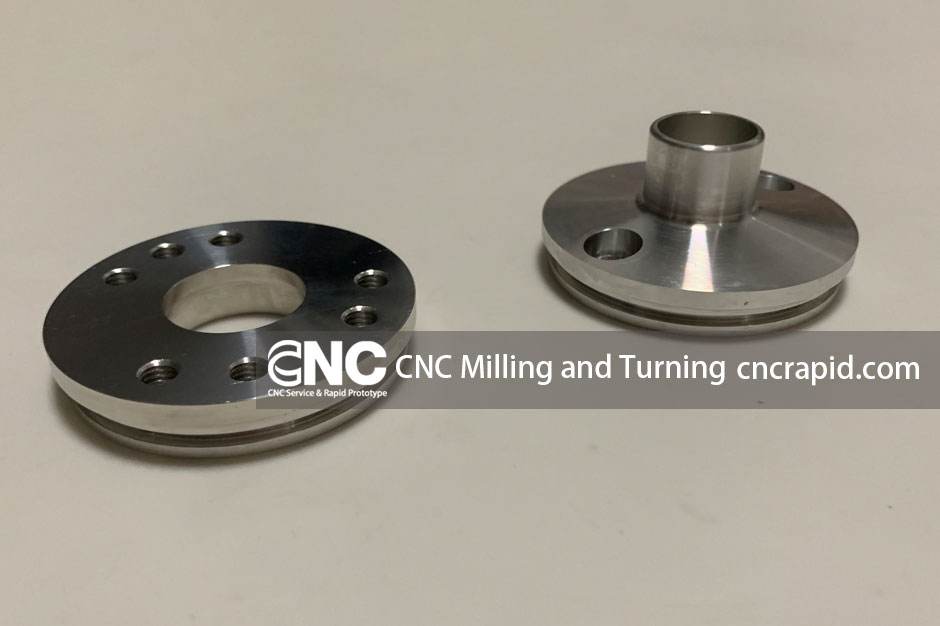

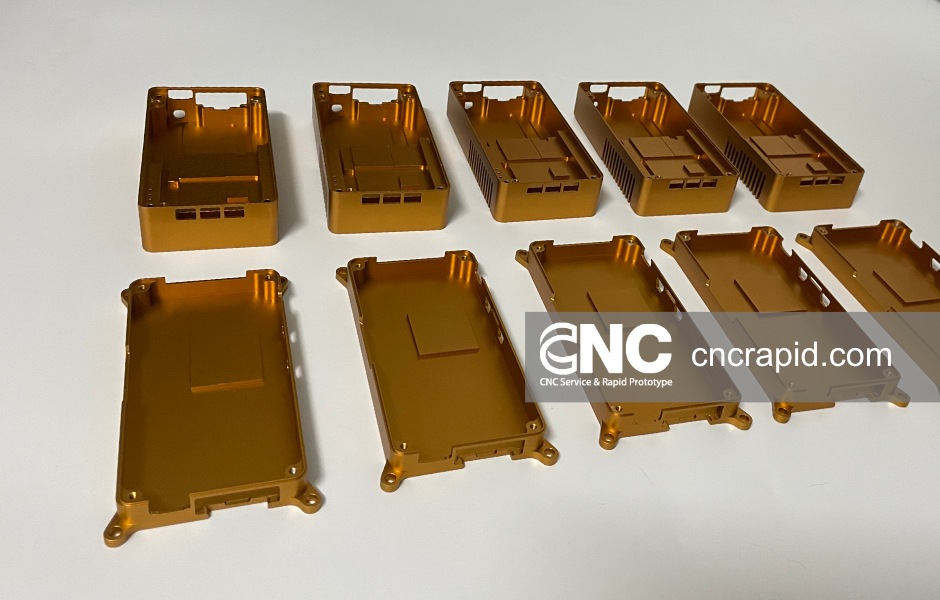

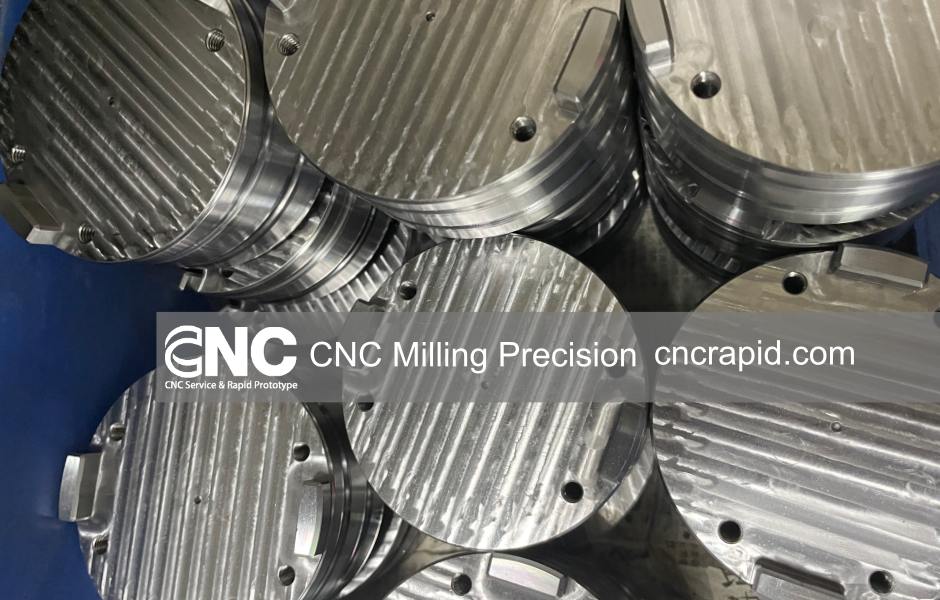

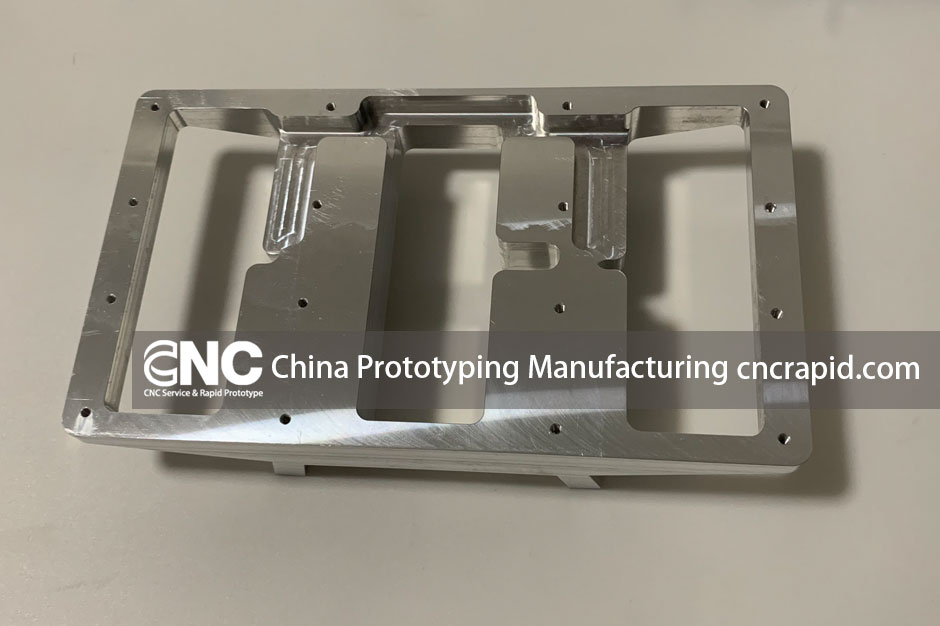

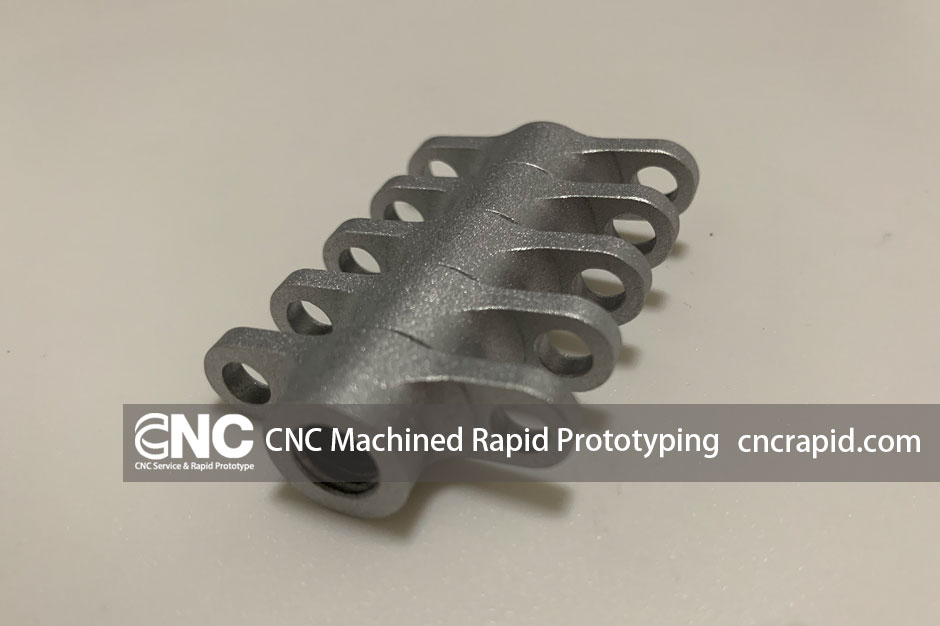

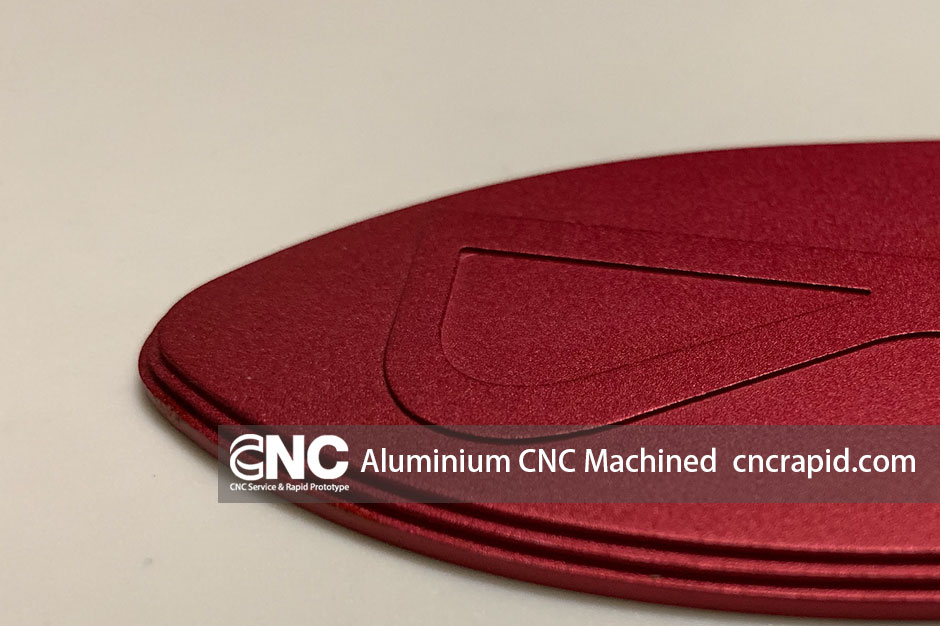

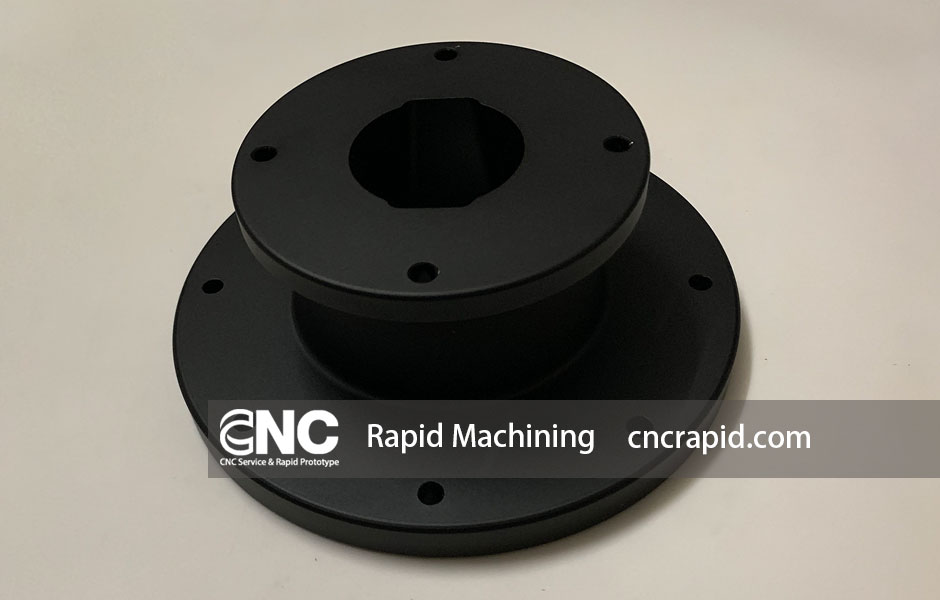

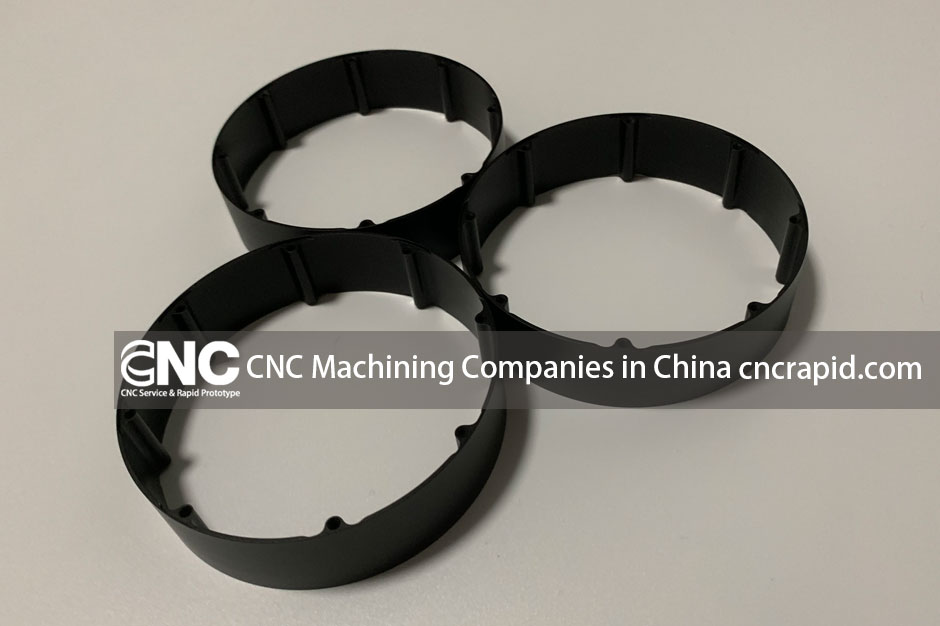

Gallery of CNC machined parts

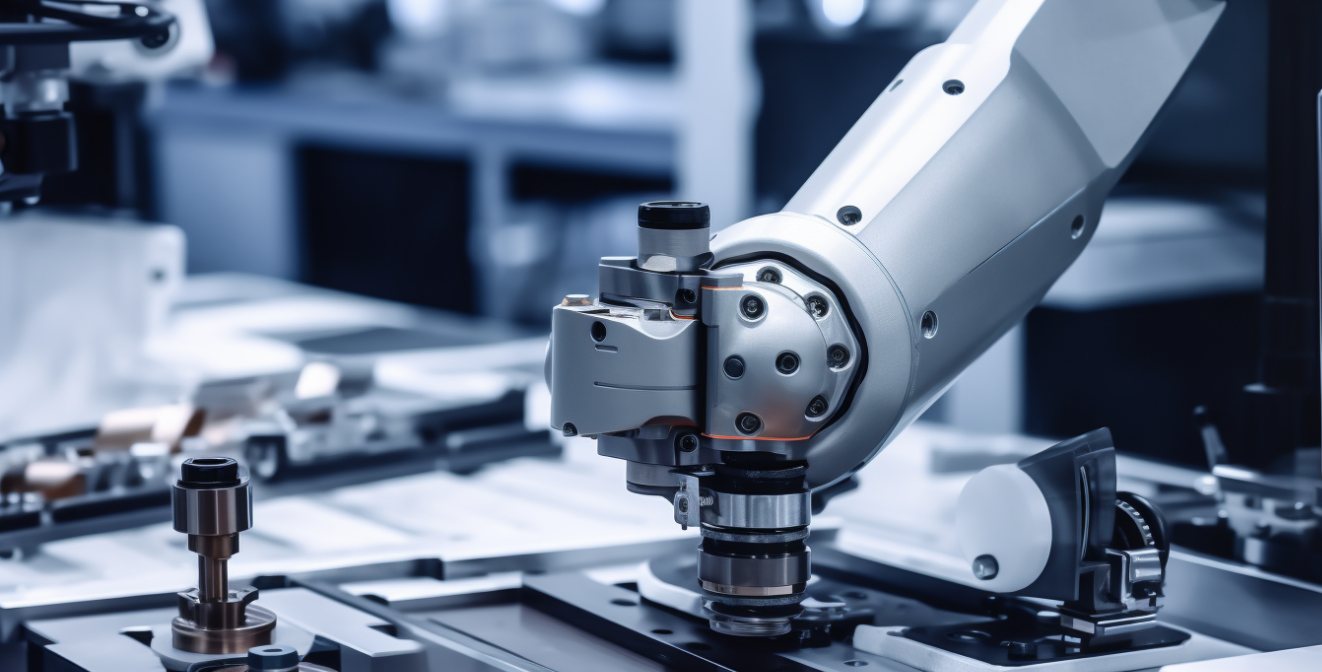

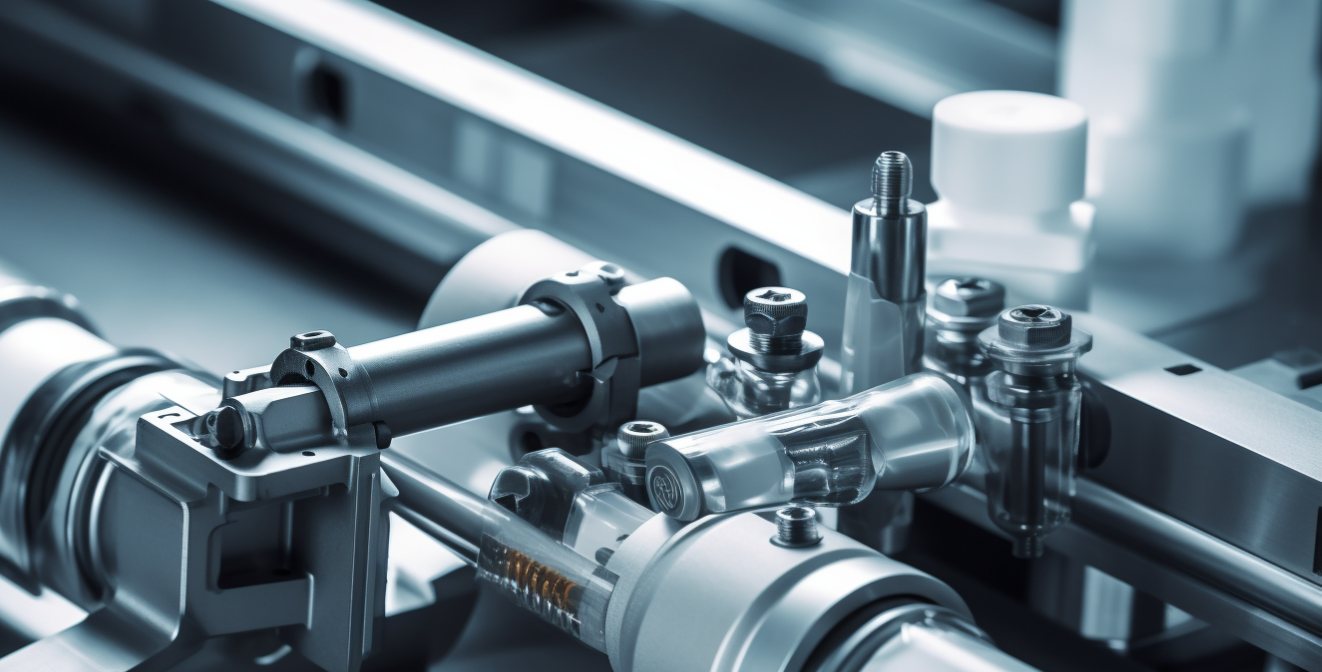

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Available surface finishes for CNC machining

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

This is our standard finish. Parts are machined and deburred, sharp edges are chamfered.

Smooth machining is like an ‘As machined’ finish but with slightly less evident machine marks. Parts are machined at a lower feed, no hand polishing is applied.

Parts are bead blasted and anodized type II. Ideal for increasing the corrosion resistance of the part.

Parts are bead blasted and an anodizing type III coating is directly applied to the surface. Ideal to improve corrosion and wear resistance of components.

Parts are brushed and then anodized type II. Ideal for increasing the corrosion resistance of the part. Typically results in a glossy color.

Powder coating is a strong, wear-resistant finish that is compatible with all metal materials.

Applicable to numerous substrates, black chrome plating is an electrochemical procedure that enhances wear resistance and provides a distinguished, dark aesthetic.

Tolerances

We adhere to the ISO 2768-f standards for CNC machining. Our standard tolerances are +/-0.1 mm (.005”), which are well-suited for most commercial and industrial applications. However, we can achieve tighter tolerances of +/-0.01mm (0.00039”) for specialized projects. Please consult with us if you require closer tolerances for your unique requirements.

Specialist industries

China CNC Machining Services

From 1 to 10000+ Parts

Custom Brass Fittings Connectors: Precision CNC Turning

In hydraulic, pneumatic, and plumbing systems, a single leaking connection [...]

Aluminum CNC Machined RF Housings

In the rapidly advancing fields of 5G telecommunications, satellite broadcasting, [...]

Custom CNC Machined Watch Cases: Aluminum Housings

The wearable technology market is booming. From advanced fitness trackers [...]

Small CNC Machined Parts: Precision Custom Aluminum Brackets & Hardware

When people think of CNC machining, they often picture massive engine blocks or large aerospace panels. However, the true heartbeat of any complex machine—whether it is a robotic arm, an optical testing device, or a [...]

CNC Machined Aluminum Housings

As electronic devices become more powerful and compact, standard off-the-shelf enclosures are often no longer sufficient. High-performance electronics—such as industrial controllers, audio amplifiers, and medical devices—require robust protection, precise mounting points, and excellent thermal management. [...]

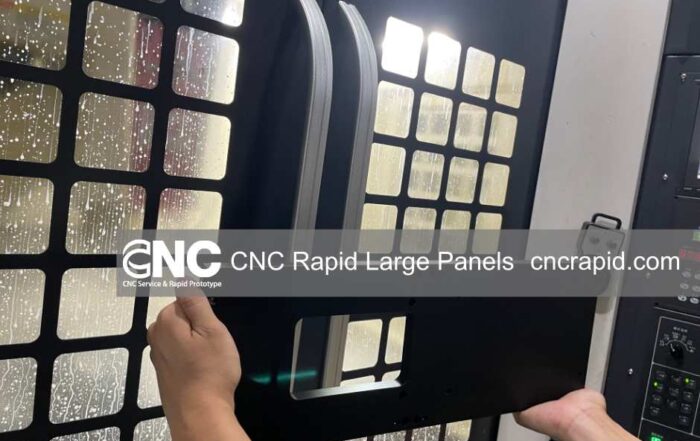

Machining Large CNC Panels: How We Maintain Perfect Flatness

Manufacturing small, complex parts is one thing, but machining Large CNC Panels presents a completely different set of challenges. When you are dealing with large aluminum base plates or mounting panels, the biggest enemy is [...]