Powder Coated

Powder coating is a strong, wear-resistant finish that is compatible with all metal materials. Powder Coating, with its amalgamation of aesthetic versatility and protective robustness, continues to be a preferred choice in various industries, especially in CNC machining.

Powder Coating is a dry finishing technique that has been widely adopted due to its environmental and practical benefits. It involves the application of a powdered polymer, typically a blend of resins, curatives, pigments, leveling agents, and other additives, which is applied electrostatically and then cured under heat to form a protective and decorative film.

The Intricacies of the Powder Coating Process

- Pre-Treatment: Parts are meticulously cleaned to remove any contaminants that might impede adhesion.

- Powder Application: Utilizing an electrostatic gun (corona or tribo guns), the powder is sprayed onto the part, adhering through electrostatic attraction.

- Curing: Parts enter a curing oven where the powder melts, flows, and chemically reacts to form a smooth, durable layer.

The Multifaceted Advantages of Powder Coating

- Superior Finish: Powder coating provides a uniform, durable, and high-quality finish.

- Environmental Impact: Absence of solvents and reduced VOC emissions make it an eco-friendly option.

- Economic Efficiency: Over-sprayed powder can be reclaimed and reused, minimizing waste.

Challenges and Mitigations in Powder Coating

- Limited to Thermally Stable Materials: Materials that cannot withstand the curing temperatures are not suitable for powder coating. However, advancements in low-temperature and UV curing powders are expanding the range of applicable materials.

- Color Changing: Frequent color changes can be time-consuming and may require thorough cleaning of the application equipment.

Applications and Case Studies

- Automotive Industry: From wheels to radiators, powder coating is extensively used for its durability and aesthetic versatility.

- Architectural Sector: Employed in window frames, railings, and other structural elements for enhanced weather resistance and visual appeal.

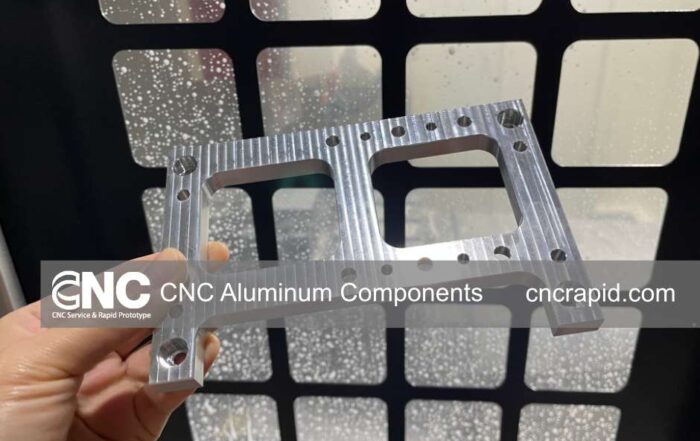

Powder Coating in CNC Aluminum Parts: A Closer Look

Aluminum, widely used in CNC machining, often undergoes powder coating to enhance its corrosion resistance and aesthetic appeal. The lightweight yet sturdy nature of aluminum, coupled with the protective and decorative attributes of powder coating, makes it a preferred choice in industries like aerospace, automotive, and consumer electronics.

Powder Coating, with its amalgamation of aesthetic versatility and protective robustness, continues to be a preferred choice in various industries, especially in CNC machining. By navigating through its challenges and leveraging its myriad of benefits, manufacturers and engineers can significantly elevate the lifecycle and visual appeal of their machined parts, ensuring they not only meet but exceed the stringent demands of their respective applications.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

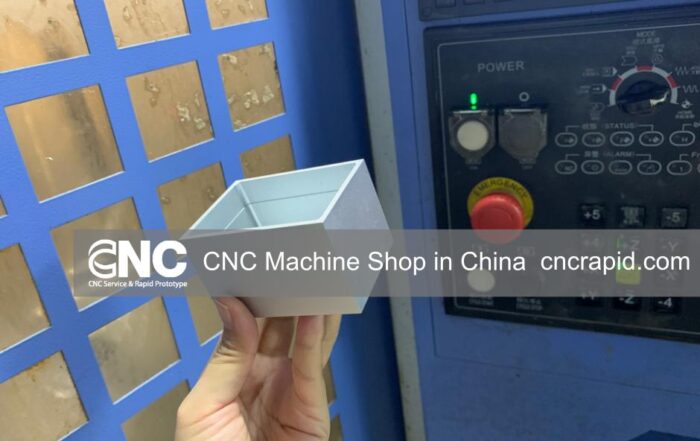

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]