Custom CNC machining is a important element in the telecommunication sector’s ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining services that help shape the future of global communications.

Our commitment to quality and innovation ensures that we remain at the forefront of the telecommunications equipment manufacturing industry. Custom CNC machining stands out as an essential technology, providing scalability, precision, and customization that are crucial for producing reliable telecommunication components. At CNC Rapid, we specialize in custom-made solutions that meet the high standards of modern telecommunications.

The Necessity of Precision in Telecommunications

Telecommunication systems are the backbone of global connectivity, supporting everything from basic voice calls to high-speed internet services. Each component in these systems must meet exacting precision standards to ensure reliable, uninterrupted service. This is where CNC machining proves invaluable.

Custom CNC Machining Solutions

CNC machining offers high flexibility and precision for telecommunication equipment manufacturing. Our custom solutions are designed to address several critical aspects:

Material Selection

- Aluminum for its lightweight and excellent conductivity.

- Copper for superior electrical properties ideal for high-frequency telecommunications.

- Stainless Steel for durability and corrosion resistance in outdoor applications.

Component Examples

- Antenna Gears and Mounts: CNC machining allows for the production of complex, bespoke designs that fit specific installation requirements.

- Satellite Dish Components: Precision-machined parts ensure that satellite dishes can withstand environmental stresses while maintaining exact alignment.

- Fiber Optic Connectors: High precision is crucial for components that facilitate fiber optic connectivity, where any discrepancy can lead to signal loss.

Scalability and Efficiency

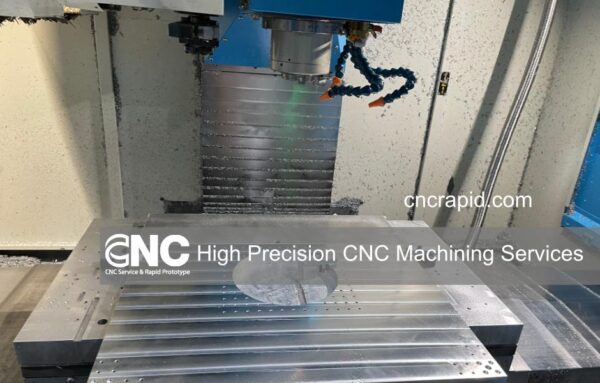

One of the biggest challenges in telecommunication equipment production is scaling manufacturing processes to meet global demand without compromising on quality. CNC machining addresses this by allowing for rapid adjustments in production with minimal downtime. Our advanced CNC equipment and expert technicians ensure that both large and small batch productions meet the same high standards of precision and quality.

Advancing Innovation with CNC Machining

At CNC Rapid, our commitment to innovation is demonstrated through our continuous investment in cutting-edge machining technologies. This enables us to support the telecommunications industry not only by producing existing designs but also by collaborating on the development of next-generation technologies.

Case Study: Enhancing Network Reliability with Custom CNC Parts

A recent collaboration involved designing and producing specialized mounting brackets for a new range of cellular network towers, intended to enhance 4G and 5G connectivity across rural areas. The brackets were machined to exact specifications to ensure optimal orientation and stability of the signal transmitters. This project highlighted our capability to adapt quickly to industry needs and deliver products that stand up to rigorous use.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!