Key Advantages of Choosing 316 Stainless Steel for CNC Machining

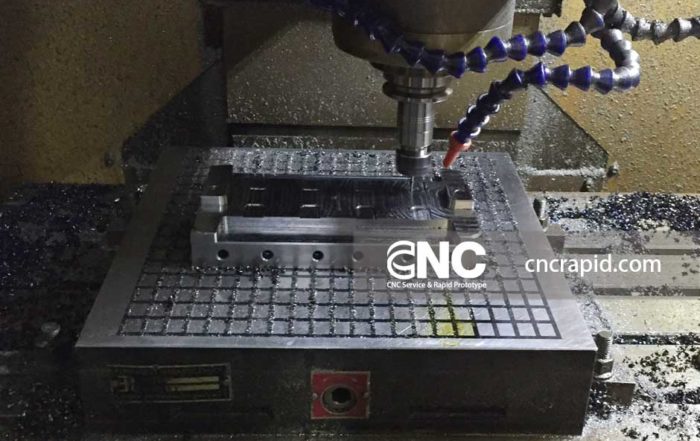

316 stainless steel is commonly used in CNC machining due to its excellent strength, high corrosion resistance and excellent machinability, making it suitable for a variety of industrial applications.

Stainless steels, 316 stands out as a material of choice for many CNC machining projects. Renowned for its unparalleled corrosion resistance and strength, it’s a material that promises both durability and elegance.

Chemical Composition of 316 Stainless Steel: Highlight the key elements that make up 316 stainless steel, such as:

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

- Carbon, Manganese, Silicon, and others.

Distinguishing Features:

- Superior Corrosion Resistance: Thanks to its molybdenum content, 316 offers enhanced resistance against chlorides like sea salt, making it ideal for marine applications.

- High Temperature Tolerance: 316 stainless steel maintains its properties even at elevated temperatures.

Machinability and Weldability: Discuss how 316 stainless steel performs in CNC machining processes, its work hardening rate, and how it compares to other stainless steel grades. Also, touch upon its excellent weldability.

Applications in CNC Machining:

- Marine Components: Due to its resistance to saltwater corrosion.

- Medical Implants: Owing to its biocompatibility.

- Chemical Processing Equipment: Resistant to a wide range of chemicals.

- High-end Jewelry: For its lustrous finish and durability.

Design Recommendations for Engineers: Offer insights on how to maximize the benefits of 316 stainless steel in design. Discuss considerations like post-machining treatments, achieving tight tolerances, and surface finishes.

316 vs. 316L: Briefly touch upon the low-carbon variant, 316L, and when it might be preferable over standard 316.

Reiterate the unmatched qualities of 316 stainless steel in CNC machining, emphasizing its versatility and the value it brings to high-end applications.

Encourage readers to reach out for more information, samples, or to discuss how 316 stainless steel can elevate their next CNC machining project.

Comparison between 304 and 316 Stainless Steel

| Property/Characteristic | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Main Alloying Elements | Chromium: 18-20%, Nickel: 8-10.5% | Chromium: 16-18%, Nickel: 10-14%, Molybdenum: 2-3% |

| Corrosion Resistance | Excellent, especially in oxidizing environments | Superior, especially against chlorides like sea salt due to molybdenum content |

| Machinability |

Good | Good, but tends to work harden |

| Weldability | Excellent | Excellent |

| Common Applications | Food and beverage equipment, construction materials, automotive components | Marine components, medical implants, chemical processing equipment, high-end jewelry |

| Cost | Generally more affordable | Typically more expensive due to molybdenum content |

| Temperature Resistance |

Maintains properties up to 870°C | Maintains properties even at slightly higher temperatures |

| Finish | Can achieve a mirror finish with polishing | Can also achieve a mirror finish, but may require more effort due to work hardening |

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

Precision 304 Stainless Steel Fixture Blocks by CNC Rapid

At CNC Rapid, we understand that every component in the machining process plays a critical role. One such component—the 304 stainless steel fixture blocks, has become indispensable in ensuring consistent, high-quality results in CNC machining. [...]

Online CNC Quote: How to Ensure Quality and Affordability

In today's fast-paced manufacturing world, finding a CNC service that offers both quality and affordability can be tough. At CNC Rapid, we've simplified this process for you. Understanding CNC Machining:CNC machining is a subtractive manufacturing [...]

Stainless steel CNC machining services China

Stainless steel CNC machining services China. We specialize in production machining services, engineering and using the latest technology to keep your prices low, without affecting quality. Throughout the years we have added materials to our list [...]

China Stainless Steel CNC Machining Shop

China Stainless Steel CNC Machining Shop. DFM Rapid’s CNC machining services offer you a one-stop CNC rapid prototyping and low-volume manufacturing solution. We have a full suite of CNC equipment to provide multi-axis milling and [...]

Stainless Steel Turned Parts China

Stainless Steel Turned Parts China. We are a CNC Machining Shop in China. CNC Machining part generally refers to piece-parts, or component parts which are custom machined to a customer’s specific requirements. If you need [...]

Stainless Steel Turned Parts Shop

Stainless Steel Turned Parts Shop. Stainless steel is an alloy of iron that is resistant to rusting and corrosion. Stainless steel is used for industrial equipment when it is important that the equipment lasts and [...]