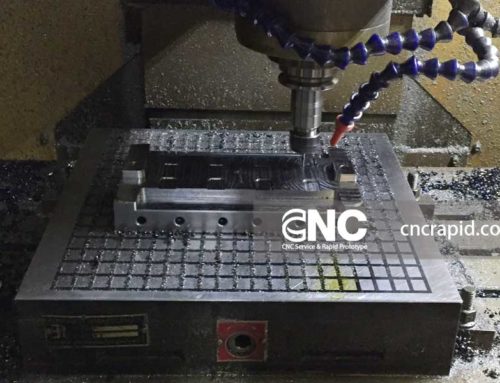

At CNC Rapid, we understand that every component in the machining process plays a critical role. One such component—the 304 stainless steel fixture blocks, has become indispensable in ensuring consistent, high-quality results in CNC machining.

What is Fixture Blocks in CNC Machining

Fixture blocks are essential tools in the CNC machining process, providing a stable and repeatable setup for workpieces. They allow manufacturers to achieve tight tolerances and high repeatability, which are crucial for industries ranging from aerospace to medical devices. The robust design of fixture blocks not only streamlines production but also minimizes errors and downtime.

Why 304 Stainless Steel?

Superior Material Properties

304 stainless steel is renowned for its excellent corrosion resistance and durability. These properties make it an ideal choice for fixture blocks that must withstand the rigors of constant use and exposure to various environmental factors. Some of the key material benefits include:

-

Corrosion Resistance: 304 stainless steel is highly resistant to oxidation and corrosion, ensuring longevity even in harsh conditions.

-

Strength and Toughness: The alloy maintains its strength and integrity under high stress, which is critical for precise machining.

-

Ease of Fabrication: This stainless steel grade is widely used due to its ease of welding and forming, allowing for complex fixture block designs without compromising performance.

The use of 304 stainless steel in fixture blocks brings about a significant enhancement in precision. The material’s inherent stability reduces the risk of dimensional changes during machining, ensuring that each component is manufactured to exact specifications. This is especially important for industries where even minor deviations can lead to significant downstream issues.

Advancements in CNC Machining with 304 Stainless Steel Fixture Blocks

Improved Workholding and Setup

One of the standout advantages of using 304 stainless steel fixture blocks is the improved workholding capability they offer. The uniformity and high-quality finish of the material allow for tighter tolerances when clamping workpieces. This means fewer vibrations and more stable machining processes, leading to superior surface finishes and overall part quality.

Enhanced Productivity

When fixture blocks are manufactured with 304 stainless steel, the overall reliability of the CNC setup increases. This translates to reduced downtime, as the fixtures are less likely to deform or wear out under continuous operation. Manufacturers can run longer production cycles with fewer interruptions, which ultimately boosts productivity and reduces costs.

Customization and Flexibility

304 stainless steel’s excellent machinability allows for highly customizable fixture blocks. Manufacturers can tailor designs to meet the specific requirements of a given project, ensuring that each block perfectly aligns with the CNC machining strategy. Whether it’s for rapid prototyping or full-scale production, these fixture blocks provide the versatility needed to adapt to various manufacturing challenges.

The industries We Serve

Aerospace and Automotive Industries

In sectors like aerospace and automotive manufacturing, precision is non-negotiable. 304 stainless steel fixture blocks have been successfully implemented in the production lines of leading manufacturers, where they contribute to the creation of components that must adhere to strict safety and performance standards. Their consistent performance under rigorous conditions makes them a trusted choice in these high-stakes industries.

Medical Device Manufacturing

The medical device industry benefits immensely from the use of 304 stainless steel fixture blocks. These fixtures ensure that components such as surgical instruments and implantable devices are machined to exacting standards. The reliability of 304 stainless steel directly translates to improved patient safety and product efficacy, making it a critical component in the manufacturing process.

Rapid Prototyping and Small-Batch Production

For companies focusing on rapid prototyping, time is of the essence. Fixture blocks made from 304 stainless steel not only speed up the setup process but also allow for quick adjustments without sacrificing precision. This flexibility is invaluable when iterating design concepts quickly and efficiently.

Best Practices for Integrating 304 Stainless Steel Fixture Blocks

Design Considerations

When designing fixture blocks for CNC applications, it’s important to consider the following:

-

Material Selection: Choose 304 stainless steel for its proven performance in demanding environments.

-

Thermal Stability: Account for thermal expansion and ensure that the design maintains dimensional accuracy under varying temperatures.

-

Ease of Maintenance: Design for easy cleaning and maintenance to extend the life of the fixture blocks.

Contact CNC Rapid Today

At CNC Rapid, we’re committed to supporting innovative manufacturing solutions that drive progress. As you explore new ways to enhance your CNC operations, consider the benefits of 304 stainless steel fixture blocks—the true backbone of machining excellence in today’s dynamic industrial environment.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!