Manufacturing small, complex parts is one thing, but machining Large CNC Panels presents a completely different set of challenges. When you are dealing with large aluminum base plates or mounting panels, the biggest enemy is material warping.

At CNC Rapid, we frequently manufacture large-scale components for industrial automation, semiconductor equipment, and medical devices. In this post, we explain our proven strategy for machining large aluminum panels while maintaining absolute flatness.

The Challenge: Why Do Large Aluminum Plates Warp?

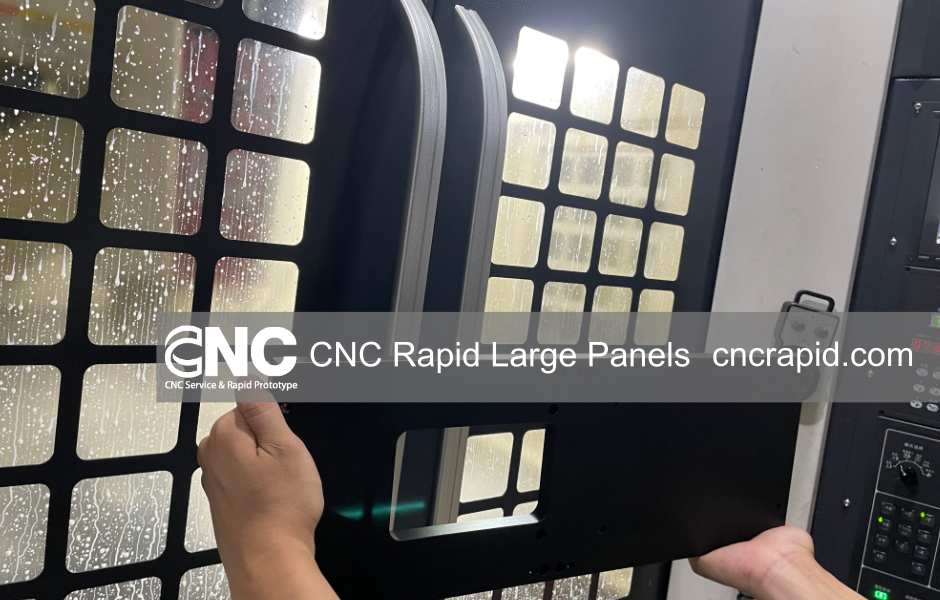

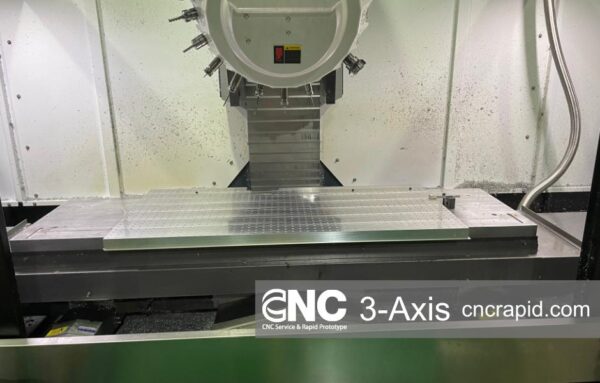

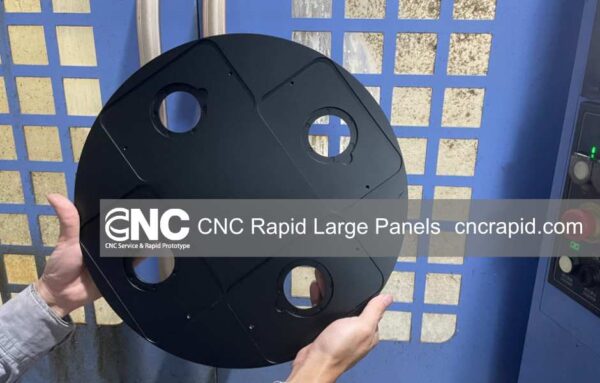

The photos in this post show two massive custom panels we recently manufactured. When machining parts of this size, you have to remove a significant amount of material (such as the large pockets and cutouts).

When you mill away the outer layers of a solid aluminum block, you release internal material stress. This stress relief causes the metal to naturally bend or bow—a phenomenon engineers call the “potato chip” effect. If a factory only uses standard milling techniques, the final panel will not sit flat on an assembly table.

Our Solution: Advanced Milling & Precision Grinding

To guarantee Perfect Flatness on our Large CNC Panels, we don’t just rely on standard CNC routing. We use a multi-step manufacturing approach:

- Smart CNC Milling Strategies

We never machine a large plate to its final dimensions in one pass. Instead, we use a roughing strategy. We machine both sides of the plate leaving a small amount of extra material. We then allow the aluminum to “relax” and release its internal stress before performing the final, light finishing cuts. - The Secret Weapon: Precision Surface Grinding

While our CNC milling centers are highly accurate, some high-end applications require extreme flatness tolerances (e.g., 0.01mm or better) across a large surface area.

For these demanding projects, we utilize our in-house Precision Grinding Machines. After the initial CNC machining, we carefully grind the large flat surfaces. Grinding removes microscopic high spots without introducing new cutting stress, resulting in a perfectly flat and parallel base plate.

Premium Surface Finish: Flawless Black Anodizing

Achieving mechanical flatness is only half the job; the cosmetic finish must also be perfect.

Large flat surfaces are notoriously difficult to anodize because any scratch, tool mark, or uneven coating becomes instantly visible. As you can see in the photos, these panels feature a flawless, uniform Black Anodized finish.

- Durability: The anodized layer provides a hard, scratch-resistant surface ideal for industrial environments.

- Aesthetics: A deep, matte black finish gives the equipment a premium, professional look while reducing light reflection (crucial for optical or laser equipment bases).

Capabilities for Large-Scale Manufacturing

Whether you need a heavy-duty machine base, a robotic mounting plate, or a custom fixture board, CNC Rapid has the facility to handle it.

- Large-format CNC milling capabilities.

- Precision grinding for extreme flatness requirements.

- Premium surface finishing, even on oversized parts.

Need a Quote for Large Aluminum Panels?

Stop dealing with warped plates and out-of-spec dimensions. Trust your large-scale projects to the experts.

Send us your 3D CAD files (STEP/IGES) and 2D PDF drawings today. Our engineering team will review your flatness requirements and provide a competitive quote within 24 hours.