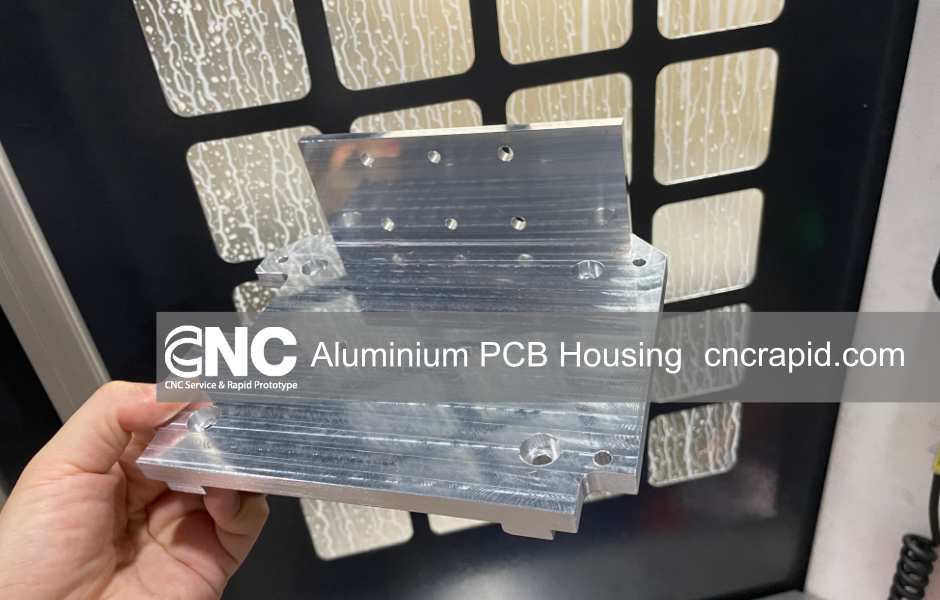

CNC Rapid is a precision-machining supplier based in Dongguan, China. More than forty percent of our yearly shipments are custom aluminium enclosures for industrial electronics, instrumentation, and IoT devices. Among the alloys we handle, 6061-T6 has become the first-choice grade for engineers who need a rigid yet lightweight aluminium PCB housing with reliable mechanical strength, good thermal conductivity, and a reasonable price point.

Why 6061-T6 for an aluminium PCB housing

6061-T6 offers a tensile strength of about 290 MPa while keeping density below 2.7 g / cm³. Its magnesium-silicon chemistry delivers a thermal conductivity near 170 W / m K—roughly six times higher than typical engineering plastics—so heat generated by power components can spread into the enclosure and dissipate through fins or the mounting surface.

The alloy also anodises cleanly, enabling either decorative finishes or hard-coat layers for wear and corrosion resistance. Compared with 5052 it machines more cleanly and holds tighter tolerances; compared with 7075 it costs less and maintains better corrosion resistance in humid environments.

Design considerations for CNC machining

A custom aluminium PCB housing often requires thin walls, long internal pockets, and multiple threaded bosses. To avoid distortion during milling we recommend:

- Keep wall thickness at least 1.2 mm. Walls below 1 mm invite chatter and local warping when heat builds up.

- Limit pocket depth-to-width ratio to 6:1 and add internal ribs where possible.

- Machine large cavities in two stages: rough with a high-feed tool, then finish with a light 0.2 mm stock allowance after the part cools.

- Use helicoil or key-locking inserts for threads above M4 when the assembly will be serviced repeatedly.

Surface finishing options

- Type II clear or black anodise for indoor devices and cosmetic appeal.

- Type III hard anodise for abrasion-prone field equipment.

- Chemical conversion coating (Alodine 1200) when the housing must remain conductive for bonding.

- Powder-coat or liquid paint for brand colours; mask mating surfaces to keep ground paths bare.

Contact CNC Rapid Today

Send your STEP or IGES data along with the PCB layout drawing or envelope dimensions. Our applications team will respond within twelve hours with manufacturing feedback, quotation including tooling if required, and lead-time options for prototype or production quantities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!