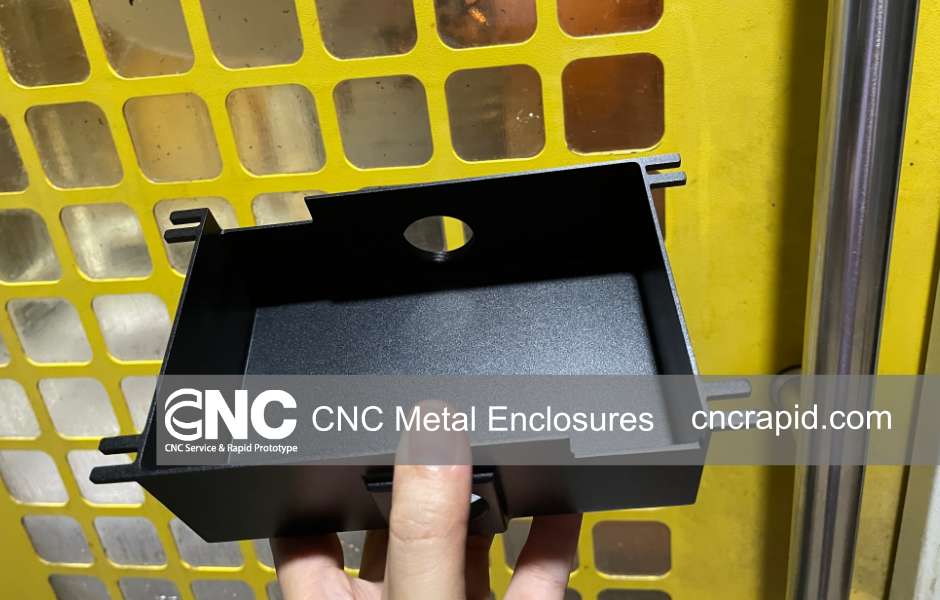

Whether you’re protecting a sensitive IoT sensor or a full‑featured control module, the metal enclosure you choose can make—or break—performance. At CNC Rapid, we machine custom enclosures from 6061‑T6 aluminum and finish them with a deep black anodized layer that looks sharp, dissipates heat, and stands up to daily wear.

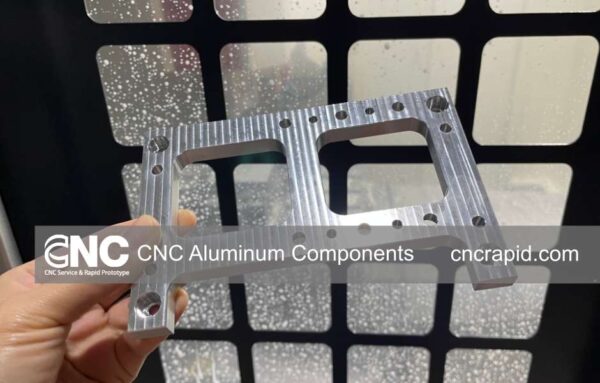

Why 6061 Aluminum Is a Natural Fit for Electronics Housings

- Excellent machinability – tight features like USB‑C ports or vent slots stay crisp without driving up cycle time.

- Balanced strength‑to‑weight ratio – lighter than steel, sturdier than plastics; perfect for handheld or wall‑mounted devices.

- Corrosion resistance – vital for outdoor gear and humid factory floors.

- Thermal conductivity – pulls heat away from PCBs better than most alloys, reducing thermal throttling.

🔗 Related read: 6061 vs. 7075—Choosing the Right Aluminum for CNC Parts

The Case for a Black Anodized Finish

- Harder surface – Type II black anodizing boosts surface hardness, cutting down on scratches during assembly or field use.

- Electrical insulation – the oxide layer prevents accidental shorts while maintaining grounding paths where you need them.

- Low‑glare aesthetics – matte black looks professional in rack systems and consumer tech alike.

- Branding options – laser‑etch logos or part numbers directly through the anodic layer for a subtle, permanent mark.

Precision Features We Machine Daily

| Feature | Typical Tolerance | Common Use |

| Counter‑bored mounting holes | ±0.05 mm | Secure PCB standoffs |

| Pocketed heat‑sink fins | ±0.1 mm depth | Passive cooling |

| EMI gasket grooves | ±0.05 mm | Shielding lids |

| USB / HDMI cut‑outs | ±0.05 mm | I/O alignment |

(Need something more demanding? We regularly hold ±0.02 mm on critical datums.)

Design Tips for Trouble‑Free CNC Enclosure Production

- Maintain minimum wall thickness of 1.5 mm for rigidity after machining and anodizing.

- Fillet internal corners (R ≥ 1 mm) to reduce tool wear and cost.

- Call out conductive masking on grounding pads before anodizing.

- Provide assembled PCB models so we can verify connector clearances early.

🔗 Need plastics too? See our guide on POM & ABS CNC Prototyping.

From Prototype to Production—The CNC Rapid Workflow

- DFM feedback in 24 hours—catch interferences or undercuts before chips fly.

- Rapid prototyping—single pieces ship in as little as three days.

- Low‑volume to mid‑volume runs—scale to 1,000 units without new tooling.

- 100 % inspection on tight‑tolerance features with CMM reports on request.

- Worldwide delivery—DHL Express arrives in North America, Europe, and Australia in 3‑5 days.

Ready to Level‑Up Your Electronics?

Send us your STEP files and target quantities today. Our engineers will recommend the best machining strategy, coating spec, and packing method so your enclosures land on the production line ready to plug and play.

Have questions about tolerances, finishes, or pricing? We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!