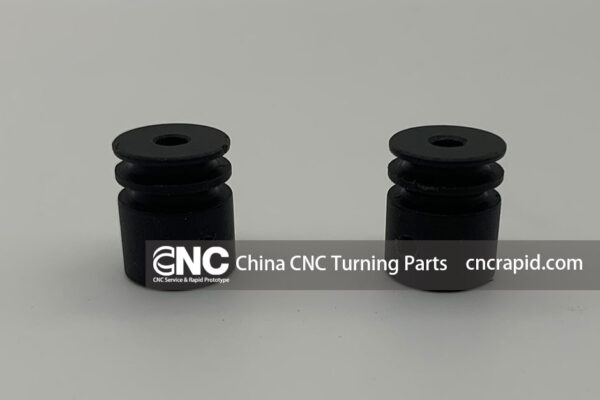

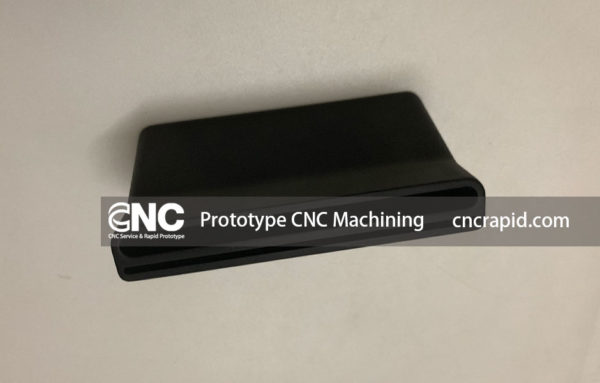

At CNC Rapid, we specialize in high-precision Black POM CNC machining services, delivering custom solutions tailored to the unique needs of our clients. Black POM (Polyoxymethylene), also known as Delrin®, is a high-performance engineering plastic known for its strength, stiffness, and excellent machinability. Our advanced CNC machining capabilities allow us to produce high-quality components from black POM that meet the exact specifications required for a variety of industries.

Why Choose Black POM for CNC Machining?

1. Superior Mechanical Properties

Black POM offers exceptional mechanical properties, including high tensile strength, stiffness, and dimensional stability. These qualities make it ideal for applications where durability and precision are critical.

2. Low Friction and High Wear Resistance

POM is well-known for its low friction coefficient and excellent wear resistance, making it suitable for parts that require smooth operation and extended service life. It is frequently used in applications involving sliding or rotating components.

3. Chemical and Moisture Resistance

Black POM resists moisture, oils, and a variety of chemicals, ensuring long-term performance even in challenging environments. This makes it a preferred material for industries such as automotive, electronics, and industrial machinery.

4. Aesthetic and Functional Versatility

The black coloration of this POM variant adds an aesthetic appeal to the material, making it suitable for visible components while retaining its functional benefits. The uniform appearance of black POM also helps hide scratches and wear, maintaining a polished look over time.

CNC Machining Capabilities for Black POM

Precision and Accuracy

Our CNC machines enable us to achieve tight tolerances and intricate details when machining black POM. Whether you need a prototype or a large production run, CNC Rapid can deliver parts with consistent quality and exceptional precision.

Custom Solutions for Complex Designs

We understand that each project has unique requirements. Our team works closely with clients to develop custom CNC machining solutions, ensuring that every black POM component meets the desired specifications. From simple shapes to complex geometries, we have the expertise to handle a wide range of designs.

Applications of Black POM CNC Machined Parts

Black POM is a versatile material with applications across numerous industries. Some common uses include:

- Automotive Components: Bushings, gears, and fasteners that require durability and low friction.

- Industrial Machinery: Custom parts such as bearings, rollers, and housings for high-performance equipment.

- Electronics: Insulators, connectors, and enclosures that demand precision and stability.

- Medical Devices: Components for diagnostic equipment and durable instruments, thanks to its chemical resistance and machinability.

- Consumer Products: Handles, levers, and casings that combine functionality with aesthetic appeal.

Surface Finishing and Post-Processing

At CNC Rapid, we offer a variety of surface finishing and post-processing options for black POM components. These include:

- Deburring: Ensuring all edges and surfaces are smooth and free from imperfections.

- Polishing: Creating a clean and uniform finish to enhance both aesthetics and functionality.

- Custom Engravings: Adding identification marks or logos as required.

Our post-processing services ensure that your black POM components are ready for use immediately upon delivery.

Quality Assurance

At CNC Rapid, quality is our top priority. Every black POM part we produce undergoes stringent quality checks to ensure it meets your exact specifications. Our advanced inspection tools, including coordinate measuring machines (CMM), guarantee precise dimensions and consistent quality for all components.

We are committed to delivering parts that not only meet but exceed your expectations, ensuring reliable performance in their intended applications.

Why Choose CNC Rapid for Black POM CNC Machining Services?

Expertise in POM Machining

With extensive experience in machining engineering plastics like black POM, CNC Rapid has the expertise to handle projects of any complexity. Our team is skilled in optimizing designs and machining processes to deliver the best results.

Advanced CNC Technology

Our cutting-edge CNC machines are equipped to produce high-precision parts with tight tolerances and complex geometries. Whether it’s a prototype or a large-scale production run, our technology ensures efficiency and accuracy.

Customization and Flexibility

We understand that every project is unique. That’s why we offer fully customizable solutions tailored to your specific needs, including material selection, surface finishing, and design optimization.

Fast Turnaround Times

We pride ourselves on our ability to meet tight deadlines without compromising quality. Our streamlined production processes and advanced equipment enable us to deliver your black POM components quickly and efficiently.

Contact CNC Rapid Today!

For high-quality Black POM CNC machining services, contact CNC Rapid today. Our team of experts is ready to assist you with custom machining solutions tailored to your specific requirements. Request a quote or consultation, and let us bring your designs to life with precision and efficiency.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!