In the world of custom manufacturing, “standard” machining is easy. But what happens when you need a part with compound angles, deep undercuts, or intricate organic shapes?

At CNC Rapid, we don’t just machine simple blocks. We provide professional 5-Axis CNC Machining Services for the most demanding industries. Whether it’s a complex aerospace housing or a custom automotive billet part, our advanced equipment and experienced engineers make the difficult look easy.

The Power of 5-Axis Machining

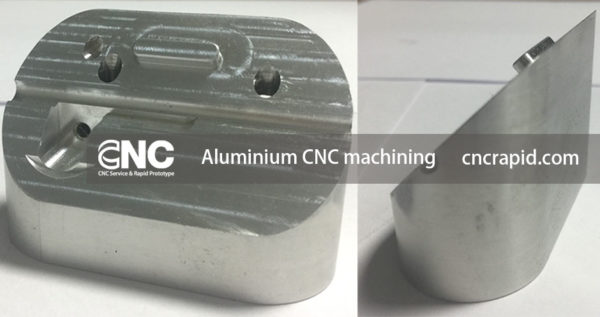

The photo above shows one of our advanced 5-Axis CNC Machines in action. Unlike standard 3-axis machines that require multiple setups (flipping the part manually), our 5-axis technology allows us to machine a part from almost every angle in a single setup.

Why this matters for your project:

- Higher Precision: Fewer setups mean zero cumulative errors. The positional accuracy is maintained throughout the entire process.

- Complex Curves: We can machine smooth, flowing curves and tapered shapes (like the one shown) that are impossible on traditional machines.

- Faster Turnaround: Less handling time means your parts get finished faster.

Tackling Tight Tolerances & Intricate Details

Precision is not just about having good machines; it’s about holding strategy. In the image above, you can see a complex structural component being machined with a rigid fixture setup.

At CNC Rapid, we thrive on Complex Geometry Machining.

- Deep Pockets & Thin Walls: We use high-speed machining strategies to cut deep cavities without causing vibration or wall deformation.

- Multi-Sided Features: Our engineers optimize tool paths to ensure that holes, slots, and features on all sides are perfectly aligned.

From Solid Block to Functional Art

We work primarily with high-grade materials like Aluminum 6061, 7075, and Stainless Steel. The result of our process is not just a functional part, but a piece of industrial art.

Look at the surface finish on our machined parts. Even before polishing or anodizing, our As-Machined Finish is smooth, clean, and free of chatter marks. This reduces the cost and time required for post-processing.

One-Stop Shop: Machining + Finishing

We understand that you don’t want a raw part; you want a finished product. CNC Rapid offers comprehensive surface finishing services to complete your vision.

From the vibrant Red Anodizing on a custom throttle body to the matte Blue Finish on a billet wheel, we manage the entire process. This ensures that the coating thickness is calculated into our machining tolerances, so your parts fit perfectly every time.

Ready to Upgrade Your Manufacturing?

Don’t let limited manufacturing capabilities hold back your design. Whether you need a single complex prototype or a low-volume production run, CNC Rapid has the technology and the team to deliver.

Contact us today. Send us your STEP/IGES files, and let’s discuss how we can bring your complex designs to life.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!