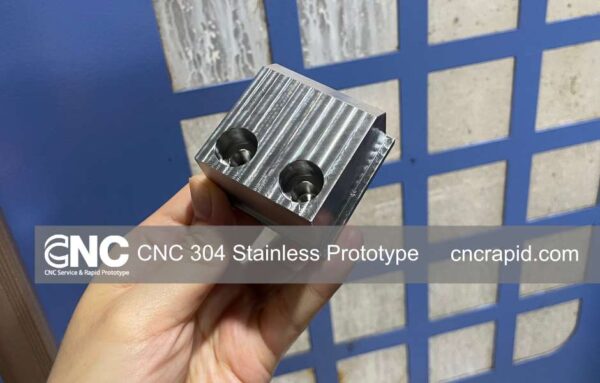

At CNC Rapid, we recently completed several batches of custom-machined steel components. Among them, a few parts are called “rivet heads”, a name that often causes confusion. Many people think of rivet heads as the small domed ends of rivets, but in manufacturing, the term can mean something very different.

In our industry, a steel riveting head refers to a tooling head used for riveting, flaring, or press-forming metal parts. These components are essential in automated equipment, assembly lines, and precision forming machines.

What Exactly Is a Steel Riveting Head?

A rivet head is a type of industrial forming tool installed on riveting machines, hydraulic presses, or custom assembly equipment. It applies controlled force to shape, flare, or fix metal components together.

Unlike a standard rivet, this kind of “rivet head” is not a fastener—it is a tool.

The rivet heads we machined have the following features:

- High-strength steel structure

- CNC turning + milling in one setup

- A flanged base with equally spaced bolt holes

- A top section with multiple precise slots or teeth

- A cylindrical inner cavity for guiding or holding workpieces

These details allow the tool to maintain alignment, resist deformation, and deliver uniform force during the forming process.

How These Rivet Heads Are Used

Based on the geometry, this type of riveting head is commonly used for:

- Flaring or expanding tubular metal parts: The segmented top structure helps guide and form the part evenly.

- Press-riveting sleeves or bushings: The inner cavity ensures concentricity during the forming operation.

- Assembly machinery tooling: The flanged base allows rigid mounting on automated stations.

- Custom forming processes in automotive, aerospace, or machinery industries: These heads are often part of a larger forming system.

CNC Machining Challenges

Producing these rivet heads requires several precision steps:

- Turning: Outer diameters, inner bores, and flanges must be machined to tight tolerances.

- Multi-axis milling: The evenly spaced top slots require consistent spacing and depth to ensure uniform forming force.

- Deburring: Because these tools interact directly with metal materials, removing sharp edges is essential for durability.

- Material selection: Most customers choose hardened steel or stainless steel for strength and wear resistance.

Why Customers Choose CNC Rapid

- Fast turnaround time

- Experienced team for complex tool geometries

- Stable dimensional accuracy across multiple batches

- Support for both prototype tools and production tooling

We provide full CNC machining support for custom riveting tools, forming dies, bushing tooling, and precision assembly components.

If you need rivet heads or other specialized forming tools, feel free to contact us for a quote.

Contact CNC Rapid Today

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!