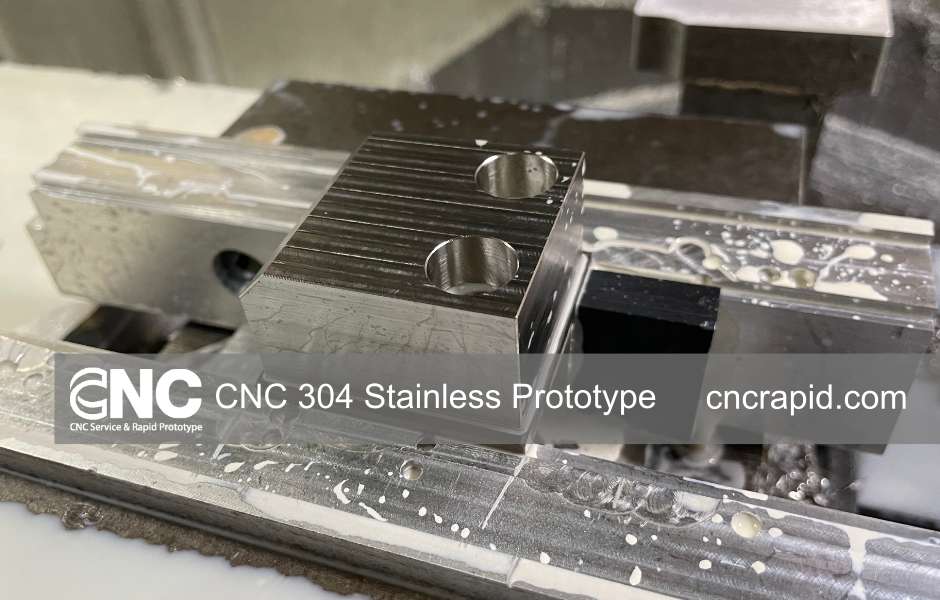

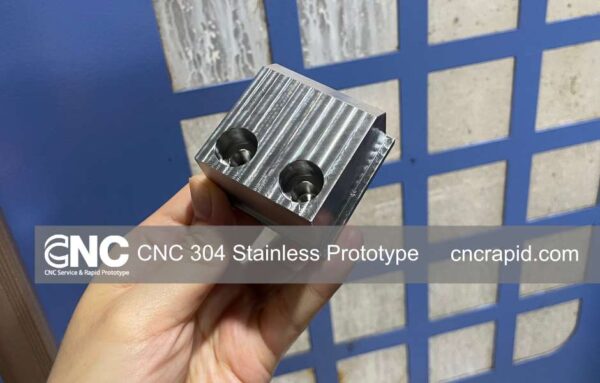

When a prototype must stay strong, fight corrosion, and look professional straight off the machine, 304 stainless steel is an easy winner. Below is a quick, data-free look at what makes this alloy special, the kinds of parts that benefit from it, and why engineers worldwide trust CNC Rapid to mill 304 every day.

What Makes 304 Stainless Stand Out?

-

Corrosion resistance that lasts

Thanks to its naturally self-healing chrome-rich surface, 304 shrugs off rain, sweat, mild chemicals, and everyday wear without any extra coatings. -

Reliable strength and toughness

It resists bending, vibration, and repeated assembly far better than most common aluminum grades, yet it still machines cleanly once feeds and speeds are dialed in. -

Clean, professional finish

A light finishing pass leaves a bright satin surface that often needs no paint or polish—ideal for client demos and production-like testing. -

Food-safe and medical-safe

Certified variants of 304 are widely used around food, beverages, and medical devices, so prototypes can move straight into regulated environments. -

Weldable and formable

If your design evolves into a welded or formed assembly later, you can keep the same alloy from prototype through production.

Why 304 Stainless Works Well for CNC Machining

-

Predictable chip formation keeps tool wear steady once the right cutters are chosen.

-

Stable cutting temperatures reduce the chance of distortion during long milling cycles.

-

Compatible with common finishing steps such as bead-blast, brushing, passivation, or laser marking, all without introducing new materials.

-

No special storage needs—bars and plates stay rust-free in normal shop conditions, simplifying inventory.

Parts That Shine in 304 Stainless

-

Outdoor brackets and mounts for drones, solar arrays, and camera rigs.

-

Consumer-facing components like watch cases, phone gimbals, and kitchen hardware where cosmetic appeal matters.

-

Medical fixtures—instrument holders, dental frames, test-rig parts that require repeated sterilization.

-

Food-processing tooling—mixing paddles, guide rails, and sensor housings exposed to moisture.

-

High-vibration assemblies—engine mounts, robotics joints, and lab equipment where stiffness and fatigue life are critical.

If a part must survive the real world—not just fit together on a desk—304 stainless is usually the safest bet.

CNC Rapid’s Edge with 304 Stainless

-

Fast, honest DFM feedback

Upload a STEP file and get manufacturability notes the same day—before you commit budget. -

Modern multi-axis mills

Our Haas and DMG machines cut complex stainless forms in one setup, reducing lead time and keeping tolerances tight. -

In-house surface finishing

Brushing, bead-blast, passivation, and laser marking happen under one roof, so you don’t lose days to secondary suppliers. -

Quality you can prove

Each shipment includes a clear inspection report and material certificate. No surprises, no excuses. -

Global express shipping

Parts leave Dongguan on express couriers and land on desks in North America, Europe, and Australia in just a few days. -

No minimum order

Whether you need a single proof-of-concept bracket or a small pilot batch, we scale to match your project—not the other way around.

Ready to mill your next 304 stainless prototype?

Upload your design, choose 304 stainless, and tell us when you need it. We’ll send a fixed quote, practical suggestions, and a shipping date you can trust—so you can focus on testing, not chasing suppliers.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!