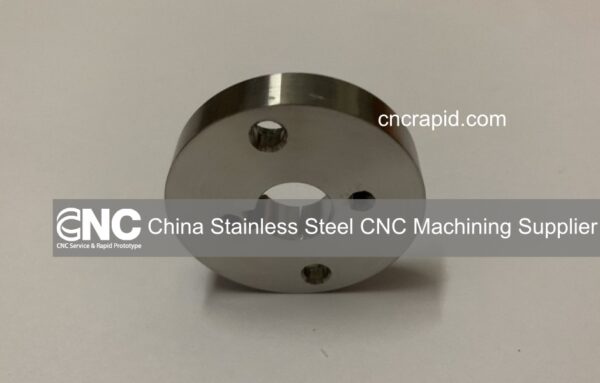

At CNC Rapid, we pride ourselves on delivering high-quality custom CNC machining solutions for a variety of materials, and stainless steel is one of our specialties. Stainless steel components are critical in industries where durability, corrosion resistance, and precision are essential. This article highlights our expertise in advanced CNC machining of custom stainless steel components, emphasizing the precision and versatility we bring to every project.

Why Stainless Steel?

Strength and Durability

Stainless steel is known for its excellent mechanical properties, making it a preferred material for components that must withstand harsh environments, high stress, or heavy use. It is highly resistant to corrosion, wear, and temperature extremes, making it suitable for industries such as electronics, automotive, medical devices, and food processing.

Corrosion Resistance

The corrosion resistance of stainless steel makes it ideal for components exposed to moisture, chemicals, or corrosive elements. This property ensures that parts maintain their integrity and performance over time, reducing the need for frequent replacements and maintenance.

Versatility in Applications

Stainless steel is used across a wide range of industries, from precision medical components to large industrial machinery. At CNC Rapid, we understand the unique demands of each application and offer customized solutions to meet specific requirements.

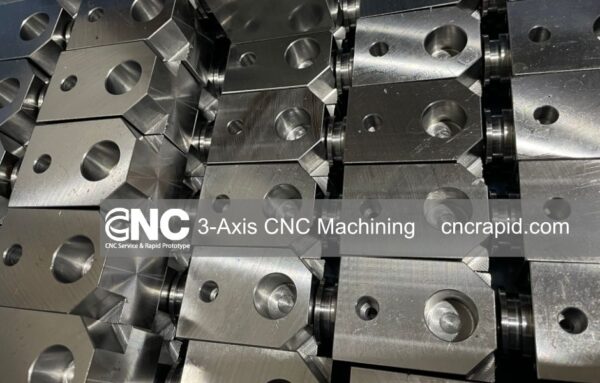

Precision CNC Machining for Stainless Steel

Advanced CNC Technology

Our advanced CNC machines are designed to handle the complexities of stainless steel machining. Stainless steel requires careful attention due to its hardness and work-hardening properties, which can lead to tool wear and thermal issues. However, at CNC Rapid, we have optimized our processes to ensure that every cut is precise, every surface is smooth, and every part meets the highest quality standards.

We utilize high-speed spindles and advanced cutting tools designed specifically for stainless steel, ensuring accurate results even for the most intricate designs. Our 5-axis CNC machining capabilities enable us to machine complex geometries and tight tolerances with ease, making us a reliable partner for industries that require high-precision stainless steel components.

Custom Machining Solutions

Whether it’s a prototype or a full production run, CNC Rapid offers custom solutions tailored to our clients’ needs. Our team of engineers and machinists works closely with clients to understand their specifications and deliver parts that meet their exact requirements. We can handle projects of any scale, from small, precision components to larger, more complex parts.

We work with a variety of stainless steel grades, including:

- 304 Stainless Steel: Commonly used for its excellent corrosion resistance and machinability.

- 316 Stainless Steel: Known for its superior corrosion resistance in marine and chemical environments.

- 17-4 PH Stainless Steel: A high-strength, precipitation-hardening stainless steel that’s ideal for electronics and medical applications.

Industries We Serve

Electronics

The electronics industry requires high-precision components that ensure optimal performance and reliability in devices. Stainless steel is often used in electronic enclosures, connectors, and heat sinks due to its durability and ability to resist corrosion. CNC Rapid’s expertise in machining stainless steel components for electronics ensures that we deliver parts that meet the exacting standards of this industry, whether it’s for consumer electronics or industrial electronic applications.

Medical Devices

In the medical field, stainless steel is widely used for surgical instruments, implants, and other medical equipment due to its biocompatibility and resistance to sterilization processes. Our precision CNC machining capabilities allow us to produce intricate medical components that meet the rigorous standards of the healthcare industry.

Automotive

Stainless steel is frequently used in the automotive industry for components that require strength, durability, and resistance to heat and corrosion. CNC Rapid has extensive experience in machining stainless steel parts for engines, exhaust systems, and structural components.

Food Processing Equipment

Stainless steel is ideal for food processing equipment due to its non-corrosive properties and ease of cleaning. At CNC Rapid, we provide custom stainless steel parts for food-grade equipment, ensuring that the components are durable, hygienic, and meet regulatory standards.

Surface Finishing and Post-Machining Services

Polishing and Surface Treatments

To enhance the functionality and aesthetics of stainless steel components, CNC Rapid offers a range of surface finishing options. From polishing to ensure a smooth, reflective surface, to bead blasting for a matte finish, we provide finishes that suit the application’s specific needs.

For components exposed to particularly harsh conditions, we also offer passivation services. Passivation enhances the corrosion resistance of stainless steel by removing surface contaminants and creating a uniform protective layer.

Quality Assurance

Every stainless steel part we machine undergoes stringent quality checks to ensure it meets the client’s specifications. We use advanced inspection tools, such as coordinate measuring machines (CMM), to verify dimensions, tolerances, and surface finishes. Our commitment to quality guarantees that every part we deliver is ready for its intended application.

Why Choose CNC Rapid

CNC Rapid’s advanced CNC machining capabilities and expertise in stainless steel make us a trusted partner for industries that demand precision, durability, and reliability. Whether you need custom stainless steel components for electronics, medical devices, automotive, or food processing equipment, CNC Rapid has the experience, technology, and commitment to deliver high-quality results.

Contact CNC Rapid Today!

For top-quality custom stainless steel components, contact CNC Rapid today. Our team is ready to assist you with tailored machining solutions that meet your exact specifications. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s stainless steel machining capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!