CNC Machined Aluminum Enclosures, crafted with precision through CNC machining, offer unmatched benefits for electronic devices. Their durability, lightweight properties, thermal conductivity, and corrosion resistance make them an ideal choice for a wide range of applications. CNC Rapid’s commitment to quality and customization ensures that each enclosure meets the highest standards, providing reliable protection and enhancing the functionality of electronic devices.

Benefits of CNC Machined Aluminum Enclosures

Durability

Aluminum is known for its exceptional strength and robustness. Enclosures made from aluminum can withstand harsh environmental conditions, providing reliable protection for sensitive electronic components. This durability ensures that devices remain operational and secure, even in demanding applications.

Lightweight

One of the standout features of aluminum is its lightweight nature. Compared to other metals, aluminum offers significant weight savings without compromising on strength. This is particularly beneficial for portable electronic devices where reducing weight can enhance user experience and portability.

Thermal Conductivity

Electronic devices generate heat, which, if not managed properly, can affect performance and longevity. Aluminum’s excellent thermal conductivity allows for efficient heat dissipation, preventing overheating and maintaining optimal operating temperatures. This is crucial for high-performance electronics that require stable thermal management.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This inherent property ensures that aluminum enclosures maintain their integrity and appearance over time, even when exposed to moisture and other corrosive elements.

CNC Machining for Aluminum Enclosures

Precision and Customization

CNC machining revolutionizes the manufacturing of aluminum enclosures by enabling unparalleled precision and customization. The CNC process involves computer-controlled machines that meticulously carve out the enclosure from a solid block of aluminum. This method allows for the creation of complex geometries and tight tolerances, ensuring that each enclosure meets exact specifications.

Quality and Consistency

CNC machining guarantees consistent quality across all manufactured enclosures. Each piece is produced with the same level of accuracy, reducing the risk of defects and ensuring a perfect fit for electronic components. This consistency is vital for maintaining the reliability and performance of the devices.

Applications in Electronic Devices

Consumer Electronics

CNC Machined Aluminum Enclosures are widely used in consumer electronics such as smartphones, tablets, and laptops. These devices benefit from aluminum’s lightweight and durable properties, enhancing their portability and longevity. Additionally, the sleek appearance of aluminum adds a premium look and feel to consumer gadgets.

Medical Devices

In the medical field, precision and reliability are critical. Aluminum enclosures provide the necessary protection for sensitive medical equipment, ensuring accurate performance and patient safety. The corrosion resistance of aluminum is also advantageous in maintaining hygienic conditions.

Industrial Electronics

Industrial electronics often operate in harsh environments where durability is essential. Aluminum enclosures offer robust protection against physical damage and environmental factors, making them ideal for industrial applications. Their ability to dissipate heat efficiently also ensures stable operation in demanding conditions.

Customization and Design Flexibility

Tailored Solutions

CNC machining allows for the customization of aluminum enclosures based on specific design requirements. Whether it’s creating unique shapes, adding intricate details, or incorporating mounting features, CNC technology provides the flexibility to meet diverse needs. This customization capability is particularly valuable for bespoke electronic devices and specialized applications.

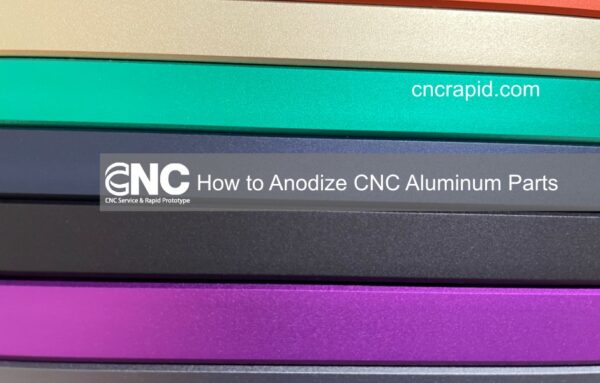

Variety of Finishes

CNC Machined Aluminum Enclosures can be finished with a range of coatings and treatments to enhance their appearance and performance. Options include anodizing for increased corrosion resistance, powder coating for a durable and attractive finish, and custom color options to match branding or aesthetic preferences.

Contact CNC Rapid Today!

For top-quality, custom CNC machined aluminum enclosures for your electronic devices, contact CNC Rapid today. Our team of experts is ready to assist you with tailored solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s manufacturing capabilities.

|

|

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!