The precision and adaptability provided by CNC machining make it an invaluable process in the production of security camera housings. Not only do these enclosures protect sensitive photographic equipment from environmental hazards, but they also ensure that the camera operates effectively under a variety of conditions.

At CNC Rapid, we understand the critical nature of security electronics and are dedicated to producing housings that meet the highest standards of quality and functionality. Our commitment to precision engineering helps ensure that our clients’ security systems are robust, reliable, and ready to protect.

The Importance of Camera Housing in Security Systems

Camera housings for security systems are more than just protective shells. They play a critical role in:

- Protecting the lens and internal components from dust, moisture, and mechanical impacts.

- Ensuring consistent performance in diverse environmental conditions, including extreme temperatures and corrosive atmospheres.

- Aiding in the discreet or overt placement of security cameras, which can be essential for both deterring criminal activity and capturing unobtrusive footage.

How CNC Machining Elevates Camera Housing Production

CNC machining brings several significant advantages to the manufacturing of camera housings:

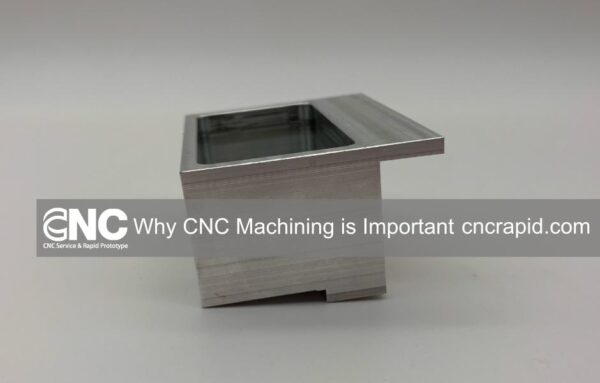

Precision Engineering

CNC machines can produce housings with extremely tight tolerances, crucial for ensuring that the camera remains stable and secure within its casing. This precision is vital for maintaining the alignment of optical components, which, in turn, impacts the quality of the surveillance footage.

Material Versatility

CNC machining works with a variety of materials, each chosen based on the specific needs of the application:

- Aluminum is frequently used for its light weight, strength, and natural corrosion resistance, making it ideal for outdoor camera housings.

- Stainless steel offers added durability and rust resistance for cameras in industrial or coastal environments.

- Plastics such as polycarbonate are used where non-conductive or transparent housings are required.

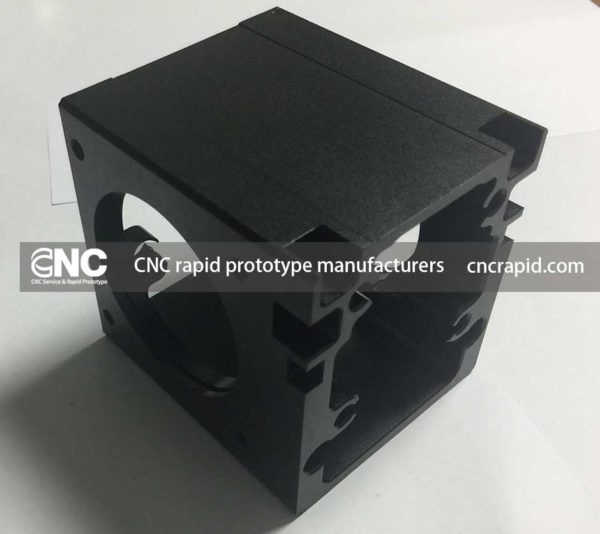

Customization

Every security scenario may demand a different design or feature in a camera housing. CNC machining allows for the customization of housings to incorporate features such as:

- Thermal insulation for extreme temperature conditions.

- Mounting options for different structures and angles.

- Aesthetic considerations that help the housing blend into or stand out from its environment, depending on security needs.

Case Study: Enhancing Urban Security with CNC-Machined Camera Housings

One illustrative example of CNC machining’s impact is seen in a project undertaken for a citywide surveillance system. The city required customized camera housings designed to fit various urban environments discreetly. CNC Rapid utilized high-grade aluminum to machine durable, weather-resistant housings that matched the specific dimensions and specifications required for each location. The project not only improved the city’s surveillance capabilities but also demonstrated the flexibility and efficiency of CNC machining in producing high-quality, reliable security components.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!