At CNC Rapid, we good at delivering high-quality custom CNC parts, even in large quantities. Today, we provide an in-depth look at our bulk CNC machining process, highlighting how we maintain precision and consistency across hundreds of parts.

The Custom CNC Parts Production in Bulk CNC Machining

Initial Design and Consultation

Every successful project begins with a thorough design and consultation phase. Our team works closely with the client to understand their specific requirements and create a detailed blueprint for the parts. Utilizing advanced CAD software, we ensure that every aspect of the design meets the client’s needs and specifications.

Material Selection and Preparation

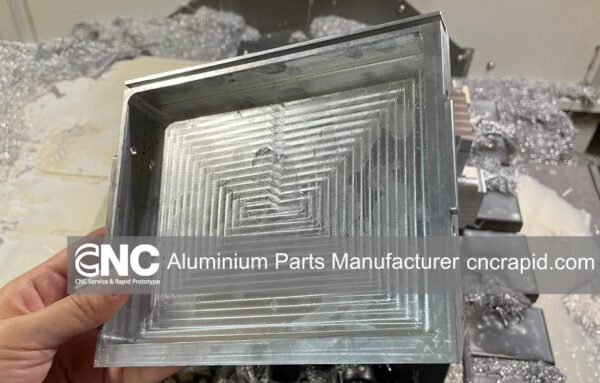

Selecting the right material is crucial for the performance and durability of the parts. For this project, we chose high-quality aluminum, known for its excellent machinability, lightweight properties, and strength. The raw materials are carefully prepared and inspected before being loaded into our CNC machines.

High-Volume CNC Machining

Setup for Bulk Production

Setting up for high-volume production requires meticulous planning and precision. Our technicians ensure that the CNC machines are configured correctly, and the materials are securely clamped and ready for machining. The setup process is critical to maintaining consistency and precision across all parts.

Advanced CNC Machines

At CNC Rapid, we use advanced CNC machines equipped with high-speed spindles and precision tools. These machines are capable of executing complex designs with tight tolerances, ensuring that each part produced is identical to the last. The automation and advanced controls of our CNC machines make them ideal for large-scale production.

Consistency in Machining

Maintaining consistency across hundreds of parts is a significant challenge that CNC Rapid meets with ease. Our CNC machines are programmed to follow the exact same path for each part, ensuring uniformity. Regular checks and adjustments are made to keep the process running smoothly and to address any minor deviations promptly.

Quality Control and Inspection

Quality Control Measures

Quality is important in our production process. Each part undergoes rigorous inspection to ensure it meets the specified dimensions and tolerances. Our quality control measures include both automated and manual inspections, utilizing advanced measurement tools such as coordinate measuring machines (CMM) to verify accuracy.

Ensuring Dimensional Accuracy

Dimensional accuracy is critical in high-volume production. Our inspection process involves measuring key dimensions and features of the parts to ensure they conform to the design specifications. Any part that does not meet our strict quality standards is reworked or discarded to maintain the overall integrity of the batch.

cnc components manufacturers

Efficiency in Bulk Production

Quick Turnaround Times

Efficiency is a hallmark of CNC Rapid’s bulk production capabilities. Our streamlined processes and advanced technology enable us to produce large quantities of parts quickly without sacrificing quality. This efficiency translates to shorter lead times and faster delivery for our clients.

Reliable Delivery Schedules

Meeting delivery schedules is essential for our clients’ project timelines. CNC Rapid is committed to providing reliable delivery, ensuring that parts arrive on time and in perfect condition. Our logistical expertise and careful planning allow us to handle large orders with precision and dependability.

Applications of Bulk CNC Parts

Industry Applications

High-volume custom CNC parts are essential in various industries, including automotive, aerospace, electronics, and medical devices. These parts play a crucial role in the functionality and performance of the final products, making precision and consistency vital.

Specific Benefits

In the automotive industry, for instance, custom CNC parts are used in engine components, brackets, and housings. These parts must meet exacting standards to ensure safety and performance. Similarly, in the electronics industry, precision parts are crucial for the reliable operation of devices. The benefits of using CNC Rapid’s services include enhanced product quality, reduced production costs, and increased efficiency.

CNC Rapid’s Expertise and Capabilities

Advanced Technology and Skilled Team

CNC Rapid is equipped with cutting-edge CNC machines and a team of highly skilled professionals dedicated to delivering excellence. Our advanced technology allows us to handle complex designs and large quantities with ease. Our team’s expertise ensures that every project is executed flawlessly from start to finish.

Bulk CNC machining at CNC Rapid exemplifies our dedication to precision, consistency, and efficiency. By leveraging advanced technology and skilled craftsmanship, we produce high-quality parts that meet the exacting standards of our clients. Whether you need a small batch or a large volume of custom CNC parts, CNC Rapid is your trusted partner for reliable and high-quality manufacturing.

Contact CNC Rapid Today!

For top-quality, custom CNC machined parts in bulk, contact CNC Rapid today. Our team of experts is ready to assist you with tailored solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s manufacturing capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!