As manufacturers strive to meet the increasing demands for precision and efficiency, CNC machining has emerged as a cornerstone technology. That’s why CNC Rapid aims to showcase the vital role of CNC machining in the production of consumer electronics, highlighting its impact on product development, precision manufacturing, and the overall market landscape.

Revolutionizing Prototyping and Production

CNC machining has transformed the way prototypes are developed in the electronics industry. Unlike traditional methods, which can be time-consuming and less precise, CNC allows for rapid prototyping with high accuracy. This speed in prototyping is crucial for electronics companies that need to iterate designs quickly to respond to consumer trends and technological advancements.

Moreover, CNC machines can handle various materials, such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more, allowing for versatility in prototype development. This capability ensures that whether a company is working on a new smartphone case or a complex motherboard, CNC machining can provide high-quality prototypes that closely resemble the final product.

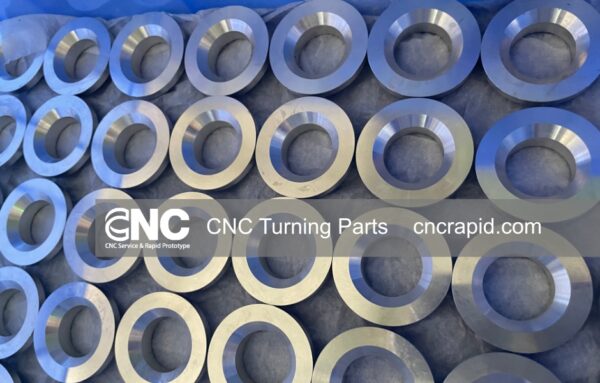

Enhancing Precision and Reliability

At the heart of consumer electronics is a need for precision. Products like smartphones, tablets, and wearables demand components that fit and function perfectly within tight tolerances. CNC machining meets these requirements by delivering exceptionally precise components. The precision of CNC machines ensures that every part, no matter how many are produced, maintains the same high standards of accuracy, crucial for the functionality and reliability of electronic devices.

Scalability and Customization

CNC machining not only supports the design and production of standard parts but also offers excellent scalability and customization options. This flexibility is particularly beneficial for producing limited edition models or custom-designed components. As consumer demand for personalized electronic devices grows, CNC technology provides a feasible solution for incorporating individual preferences into mass production.

Supporting Miniaturization

As consumer electronics continue to shrink in size, manufacturers face the challenge of producing smaller, more compact components. CNC machining rises to this challenge by enabling the production of micro-scale parts that are essential for the miniaturization trend. With advanced CNC equipment, manufacturers can produce parts that push the boundaries of what’s possible in terms of size and detail, enabling the development of smaller, yet more powerful electronic devices.

Your Partner in CNC Machining – CNC Rapid

At CNC Rapid, we understand the critical role of precision CNC machining in various industries, especially in consumer electronics production. With years of experience and advanced CNC technology, we are equipped to handle the diverse needs of the electronics industry as well as other sectors requiring high-precision machining. Whether you need components for small gadgets or large industrial machines, our skilled team is ready to deliver high-quality, custom CNC machining solutions tailored to your specific requirements.

By choosing CNC Rapid as your CNC machining partner, you’re not just getting precision parts; you’re also gaining a collaborator who is committed to driving your project’s success. We pride ourselves on our ability to adapt to the unique challenges of each industry, ensuring that your components meet the highest standards of quality and precision.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!