The Significance of Mild Steel 1018 in CNC Machining:

Mild Steel 1018 stands out as a material of choice in CNC machining due to its machinability, weldability, and ductility. Its application across various industries, from automotive to construction, testifies to its versatility and reliability. By opting for Mild Steel 1018, manufacturers and engineers are ensuring the production of high-quality, durable components while also embracing sustainable manufacturing practices.

Mild Steel 1018, recognized for its excellent machinability and weldability, has become a staple in various industries, particularly in CNC machining. This article explores the intrinsic properties, applications, and advantages of utilizing Mild Steel 1018 in CNC machining processes.

Key Properties of Mild Steel 1018

- Machinability: Mild Steel 1018 is renowned for its superb machinability, ensuring smooth and efficient machining processes.

- Weldability: Its excellent weldability allows for secure joining without compromising structural integrity.

- Ductility: The material is known for its ductility, allowing it to be formed into various shapes without breaking.

- Surface Hardening: Mild Steel 1018 can be easily case hardened, providing additional wear resistance on the surface while maintaining ductility.

CNC Machining and Mild Steel 1018

The machinability of Mild Steel 1018 makes it a prevalent choice for CNC machining. Its ability to be easily cut and formed allows machinists to create precise, complex components while maintaining a smooth production flow and minimizing material waste.

Applications Across Various Industries

- Automotive Industry: Employed in manufacturing various auto parts due to its machinability and strength.

- Construction Industry: Utilized for creating structural components, leveraging its strength and weldability.

- Manufacturing: Essential for manufacturing fixtures, mounts, and various other components due to its versatility.

Designing with Mild Steel 1018

When designing for CNC machining with Mild Steel 1018, considerations around its mechanical properties, such as tensile strength and hardness, become pivotal. Ensuring designs accommodate its machinability and weldability will result in components that are not only precise but also functionally robust.

Sustainability Considerations

Mild Steel 1018 is not only functionally advantageous but also aligns with sustainable manufacturing due to its recyclability. Its lifecycle from production, usage, to recycling demonstrates a commitment to reducing environmental impact and promoting sustainable practices in manufacturing.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

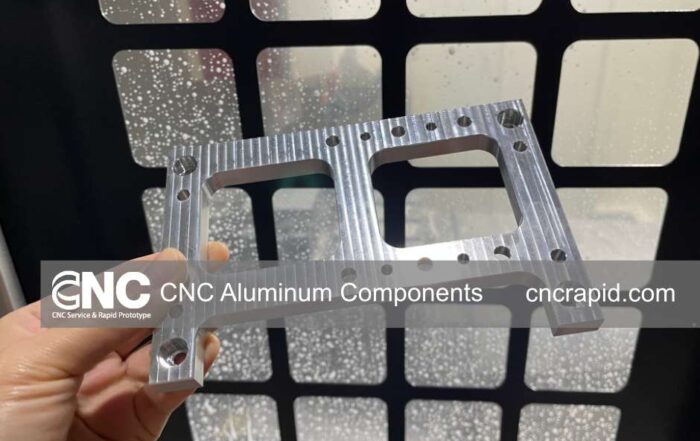

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

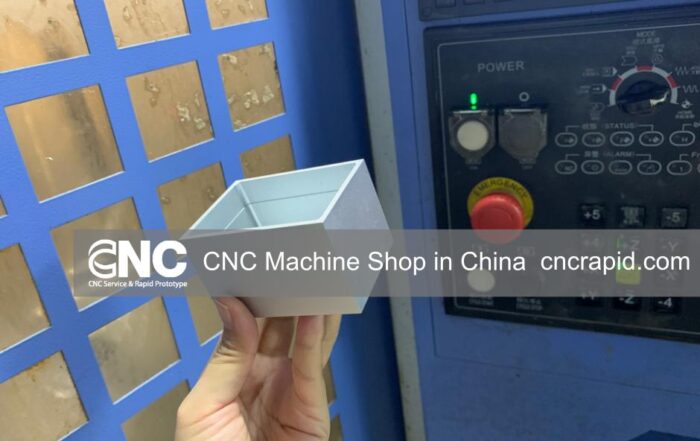

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]