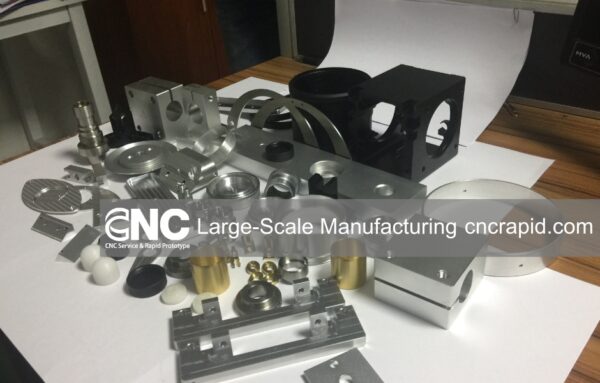

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a proven track record and advanced capabilities, we ensure that every component we produce enhances the functionality and reliability of your electronic devices.

The Need in Custom CNC Machined Parts for Electronic Devices

Electronic devices often require custom components that fit specific design and functional requirements. Custom CNC parts are crucial for:

- Enhanced Performance: Custom parts ensure optimal functionality and performance of electronic devices.

- Design Flexibility: Tailor-made components can be designed to fit unique specifications, enabling innovative product designs.

- Durability: Precision machining guarantees parts that are robust and reliable, essential for the longevity of electronic devices.

Types of Custom CNC Machined Parts for Electronic Devices

Brackets

Custom brackets play a vital role in the assembly and structural integrity of electronic devices. They provide necessary support, securing various components in place, and ensuring stable operation.

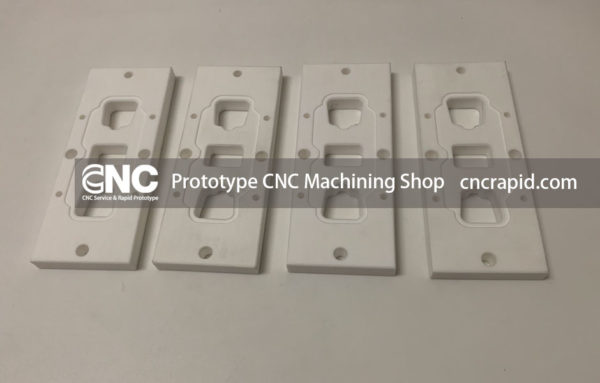

Housings and Enclosures

Precise housings and enclosures protect sensitive electronic components from environmental factors such as dust, moisture, and physical damage. CNC machined enclosures ensure a perfect fit, enhancing the overall device reliability.

Heat Sinks

Effective heat management is critical in electronic devices. Custom CNC machined heat sinks dissipate heat efficiently, maintaining optimal operating temperatures and preventing overheating.

Connectors and Mounts

Custom connectors and mounts are essential for establishing secure and reliable connections between different components. Precision machining ensures these parts meet exact specifications, facilitating seamless integration.

Benefits of Custom CNC Machined Parts for Electronic Devices

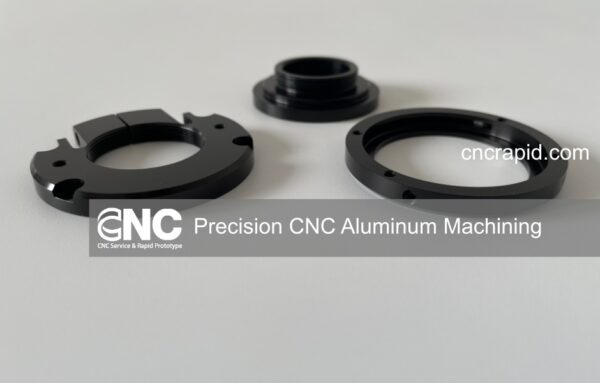

Precision

CNC machining offers unparalleled precision, producing parts with tight tolerances and intricate details. This level of accuracy is essential for the complex requirements of electronic devices.

Customization

CNC machining provides the flexibility to create parts tailored to specific design and functional needs. Whether it’s unique shapes, sizes, or features, CNC Rapid can accommodate diverse requirements.

Material Selection

CNC machining supports a wide range of materials, including various metals and plastics. This versatility allows for the selection of the best material for each specific application, ensuring optimal performance and durability.

Rapid Prototyping

The ability to quickly produce prototypes is a significant advantage of CNC machining. This speed allows for rapid testing and iteration, enabling faster development cycles and time-to-market.

CNC Rapid’s Capabilities and Expertise

CNC Rapid is equipped with advanced CNC machines and advanced technology, ensuring the highest quality standards for custom parts. Our team of experts brings extensive experience in the electronics industry, consistently delivering parts that meet stringent requirements.

Contact CNC Rapid Today!

For top-quality, custom CNC machined parts for your electronic devices, contact CNC Rapid today. Our team of experts is ready to assist you with tailored solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s manufacturing capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!