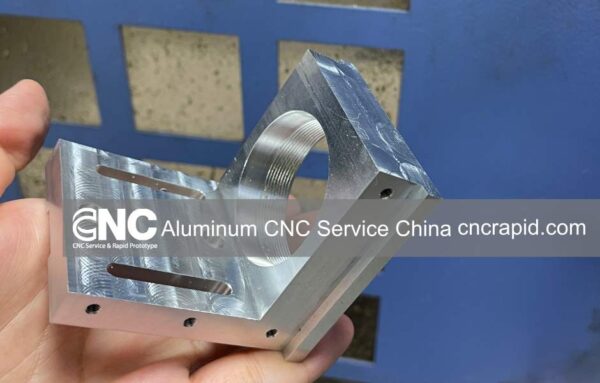

CNC Parts Machining. Welcome to the world of precision and speed, where we transform raw materials into high-quality CNC machined parts. At DFM Rapid, also known as CNC Rapid, we harness the power of subtractive manufacturing, using cutting-edge tools to carve out your desired parts from a block of raw material. Our promise? Speed, quality, and precision.

Our Capabilities

With a fleet of 20 CNC machines, we’re equipped to handle both your prototype and production demands. Our experienced engineers, armed with advanced software and equipment, ensure that every part we produce meets your exact specifications.

We offer a variety of finishes for different materials: anodized and powder coating for aluminum CNC parts, plating for steel CNC parts, and sandblasting for plastic CNC parts. Our maximum part size is 2000 x 600 x 600 mm (78.7 x 23.6 x 23.6 in), and we maintain a standard tolerance from +/-0.01mm to +/-0.15mm.

CNC Turning

Our CNC lathes offer high-speed, quality turning of both plastics and metals, creating complex external geometries and internal bores. This service is available for prototypes through to low-volume production.

CNC Milling

CNC milling, on the other hand, is perfect for applying a machined surface finish on plastic or metal, or for creating intricate 3D shapes. We utilize both domestic and imported 3, 4, and 5-axis CNC machining centers to deliver the best results.

Materials We Work With

We work with a wide range of plastic and metal materials, including but not limited to:

- Plastics: ABS, Polycarbonate, Nylon, Delrin, HDPE, Polypropylene, Acrylic

- Metals: Aluminum, Stainless Steel, Mild Steel, Tool Steel

Why Choose DFM Rapid’s CNC Machining Services?

Our CNC machining services offer numerous benefits:

- Flexibility: Our computer-controlled CNC machines can easily adapt to complex machining operations.

- Cost-effectiveness: Our efficient process reduces material wastage and labor costs.

- Efficiency: Our machines can produce multiple identical components, ensuring consistency in every part.

- 24/7 Operation: Our machines are designed for continuous operation, ensuring we meet your deadlines.

Ready to Start Your Project?

If you need metal or plastic parts machined for prototypes or production, don’t hesitate to get a quote online. You can also reach us at [email protected]. Please include the following information in your request:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for considering DFM Rapid for your CNC machining needs. We look forward to bringing your designs to life!