At CNC Rapid, precision and advanced technology are at the core of our operations. Today, we provide an inside look at our 3-axis CNC machining in action, highlighting the meticulous steps involved from setup to execution.

The 3-Axis CNC Machining in Action

Setup Phase

The journey of creating a precision part begins with the setup phase. Our skilled technicians start by securely clamping the raw material onto the 3-axis CNC machining center. This setup is crucial to ensure the material remains stable during the machining process, allowing for accurate and precise cutting. The material is carefully positioned and fixed using clamping systems, guaranteeing it is ready for the next phase.

Machining Phase

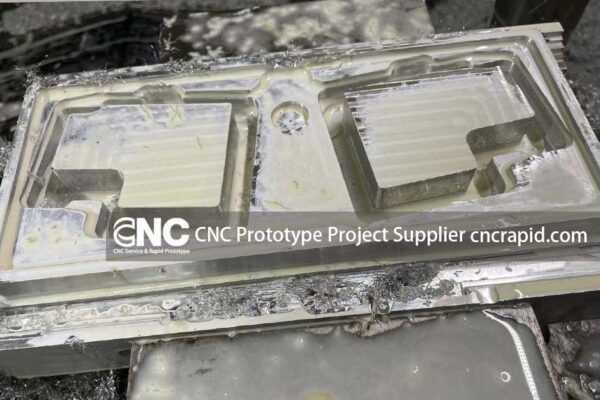

Once the setup is complete, the machine’s doors are closed, and the 3-axis CNC machining process begins. The CNC machine, programmed with precise instructions, starts milling the material. The three axes (X, Y, and Z) move in perfect harmony, guided by computer numerical control, to carve out the desired shape and features from the raw material. The high-speed spindle and cutting tools work meticulously to achieve the tight tolerances and intricate details required for each part.

Detailed Look at CNC Machining Center

Our 3-axis CNC machining center is equipped with advanced features that enable high precision and versatility. This machine is capable of handling a wide range of materials, including metals and plastics, making it ideal for producing various parts and components for different industries. The CNC machining center at CNC Rapid boasts:

- High-Speed Spindles: Ensuring efficient and accurate cutting.

- Precision Tools: Allowing for intricate details and tight tolerances.

- Automated Controls: Enhancing consistency and reducing the risk of errors.

Benefits of 3-Axis CNC Machining

Precision and Accuracy

3-axis CNC machining is renowned for its precision and accuracy. The ability to control the movement of the cutting tool along three axes ensures that every part is machined to exact specifications. This precision is crucial for applications where even the slightest deviation can impact performance.

Efficiency

The efficiency of 3-axis CNC machining is another significant benefit. The automated nature of the process allows for rapid production of parts, reducing lead times and increasing overall productivity. This efficiency is particularly advantageous for large-scale manufacturing projects.

Versatility

3-axis CNC machining offers exceptional versatility. It can produce complex geometries and detailed parts that would be challenging or impossible to achieve with traditional machining methods. This versatility makes it suitable for a wide range of applications, from aerospace to electronics.

CNC Machining Application

At CNC Rapid, our 3-axis CNC machining capabilities are utilized to produce a variety of parts and components. For instance, we manufacture custom brackets, housings, and other intricate parts for electronic devices. These components require precise dimensions and high-quality finishes to ensure they function correctly and meet our clients’ standards. The photos taken today capture the machining process in action, providing a glimpse into the precision and efficiency of our operations.

CNC Rapid’s Expertise and Technology

CNC Rapid is equipped with cutting-edge technology and a team of highly skilled professionals dedicated to delivering excellence. Our advanced CNC machines, combined with our commitment to quality, enable us to meet the stringent requirements of our clients. We continuously invest in the latest technology and training to ensure we remain at the forefront of the CNC machining industry.

Contact CNC Rapid Today!

For top-quality, custom CNC machined parts, contact CNC Rapid today. Our team of experts is ready to assist you with tailored solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s manufacturing capabilities.

|

|

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!