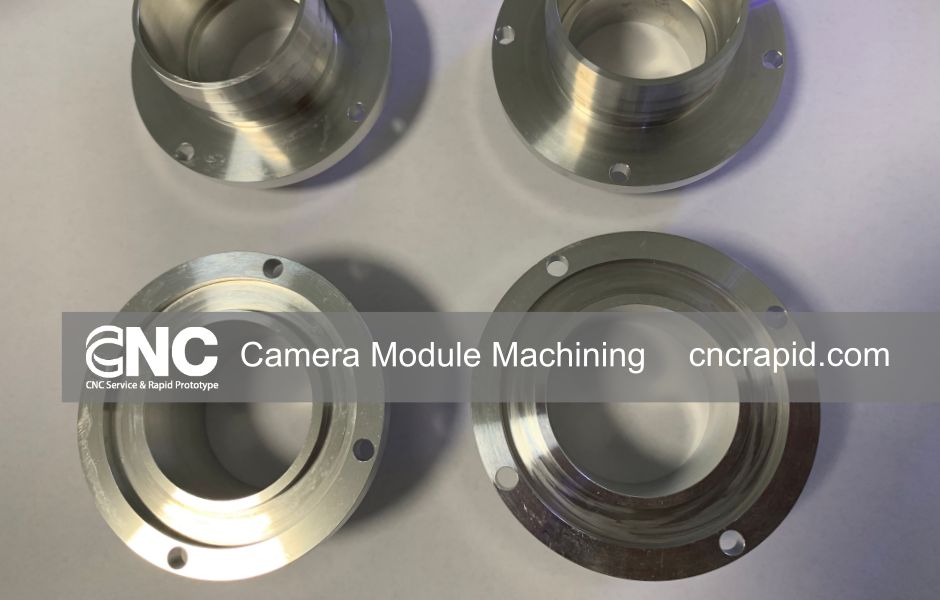

At CNC Rapid, we specialize in utilizing CNC machining to elevate the quality and performance of camera modules through precision engineering and prototyping services.

With our expert services, clients can enhance the quality of their products and accelerate the development of new technologies. If you are looking to improve the precision and quality of your camera modules, contact CNC Rapid today to discover how our services can benefit your next project.

The Importance of Precision in Camera Modules

Camera modules are integral to numerous electronic devices, requiring exceptionally high precision to ensure image clarity and functionality. Precision CNC machining helps achieve these stringent specifications with unmatched accuracy, making it an ideal choice for camera module fabrication.

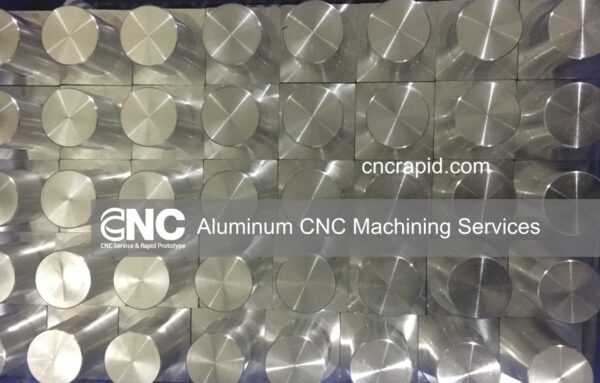

Material Selection for Optical Excellence

Our material expertise allows us to select the best substrates for optical applications, including aluminum, brass, and engineered plastics, which are known for their durability and minimal interference with camera functionality. Each material is chosen to enhance the optical properties required for high-quality imaging.

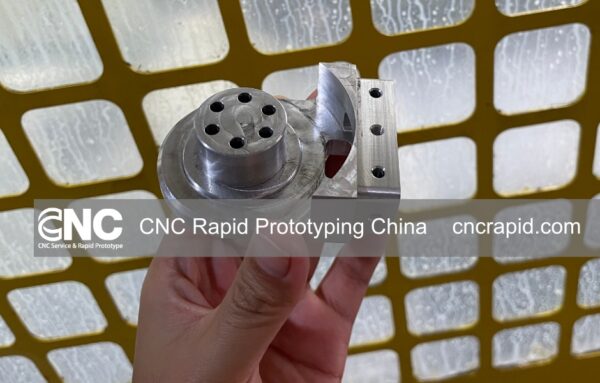

CNC Rapid’s Prototyping Services

At CNC Rapid, we believe that innovation is key to advancement in the electronics industry. Our prototyping services are designed to support this belief by providing our clients with the ability to rapidly develop and test camera modules before mass production.

Rapid Prototyping for Faster Time to Market

Our advanced CNC machinery and skilled technicians enable us to turn designs into prototypes quickly, significantly reducing the development time for new products. This rapid prototyping not only allows for faster iterations but also helps identify potential issues early in the development process, ensuring that the final products are both innovative and of high quality.

Case Studies of Success in Camera Module Production

We have partnered with several leading electronics companies to enhance their product lines with superior camera modules. These collaborations often involve complex specifications and tight tolerances that our CNC machining processes can meet consistently. By providing detailed case studies, we illustrate our capability to handle projects that require high precision and customization.

Why Choose CNC Rapid for Camera Module Machining?

- Precision and Reliability: Our CNC machining processes ensure that every component meets strict specifications with high repeatability.

- Material Expertise: We select materials that optimize the performance and durability of camera modules.

- Customization and Flexibility: We offer customized solutions that meet the unique needs of our clients, adapting to changes and requirements with flexibility.

- Support for Innovation: Our rapid prototyping services allow for quick testing and refinement, supporting the innovative efforts of our clients in the electronics industry.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!