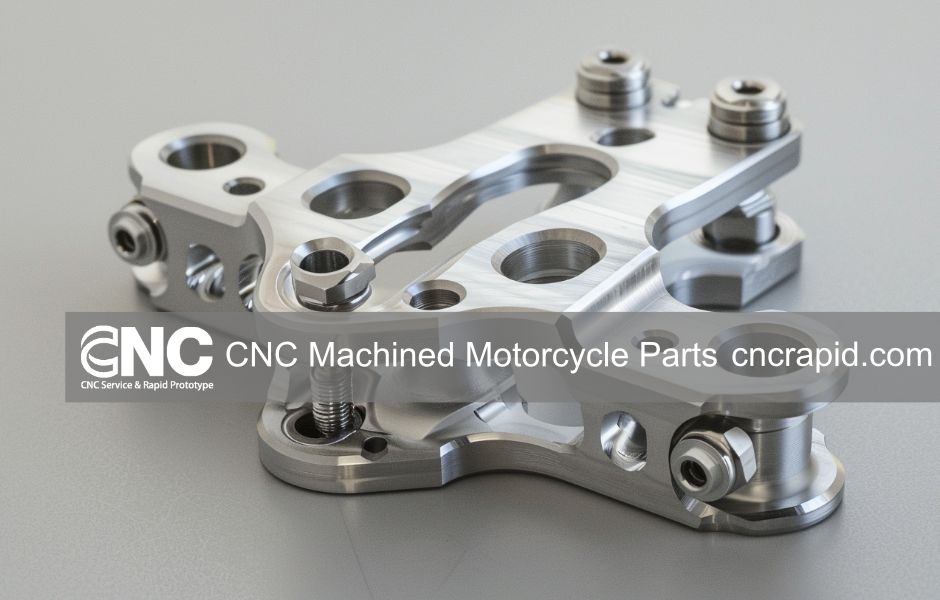

Motorcycle enthusiasts are always looking for ways to enhance their bikes, aiming for a perfect blend of performance, durability, and aesthetics. One of the most effective ways to achieve this is by opting for CNC machined motorcycle parts. These components, crafted with precision and high-quality materials, offer numerous advantages that can significantly improve your riding experience.

|

|

What Are CNC Machined Motorcycle Parts?

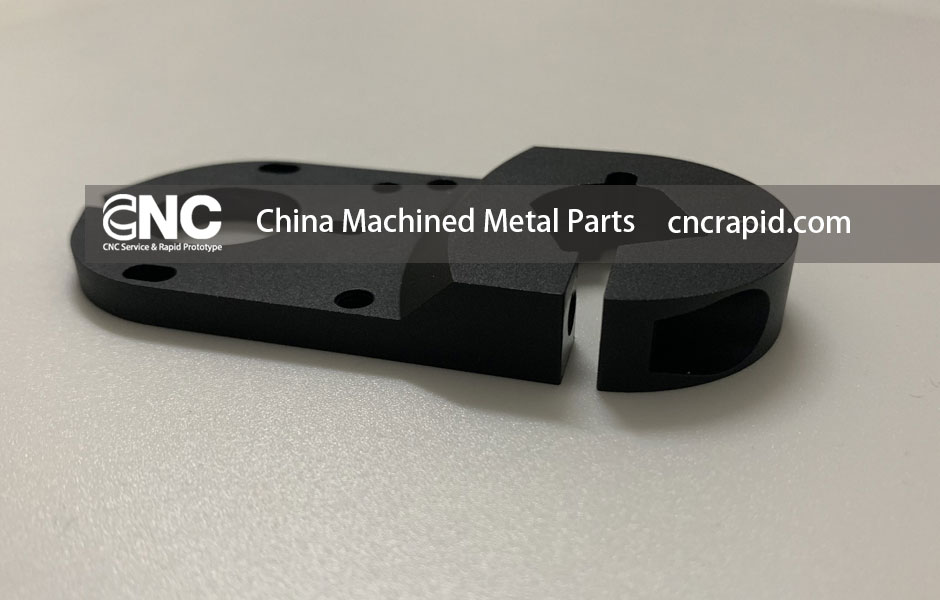

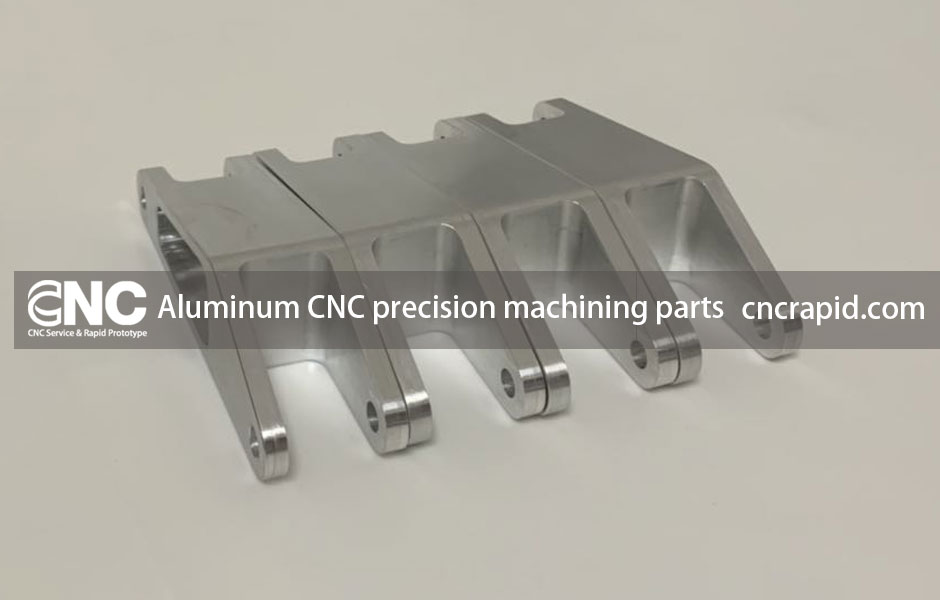

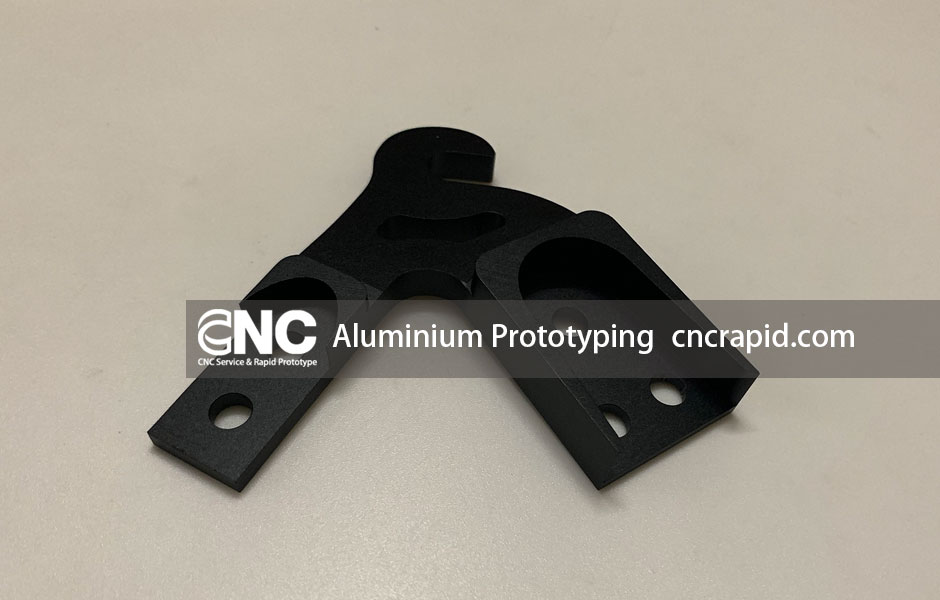

CNC machining is a manufacturing process that uses computerized controls to operate machinery and produce precise parts. In the context of motorcycle parts, CNC machining involves creating components from various materials, such as aluminum, titanium, and steel, with high accuracy. This process ensures that each part meets exact specifications, resulting in superior quality and performance.

|

|

Benefits of CNC Machined Motorcycle Parts

- Unmatched Precision CNC machining allows for incredible precision, often within a few micrometers. This level of accuracy ensures that each motorcycle part fits perfectly, reducing wear and tear and enhancing the bike’s overall performance.

- Enhanced Performance CNC machined parts are designed to optimize the motorcycle’s performance. Components like brake calipers, engine parts, and suspension components can be fine-tuned to improve handling, speed, and responsiveness.

- Superior Durability The materials used in CNC machining are typically more durable than those in mass-produced parts. This means that CNC machined motorcycle parts can withstand higher stress and are less likely to fail under extreme conditions.

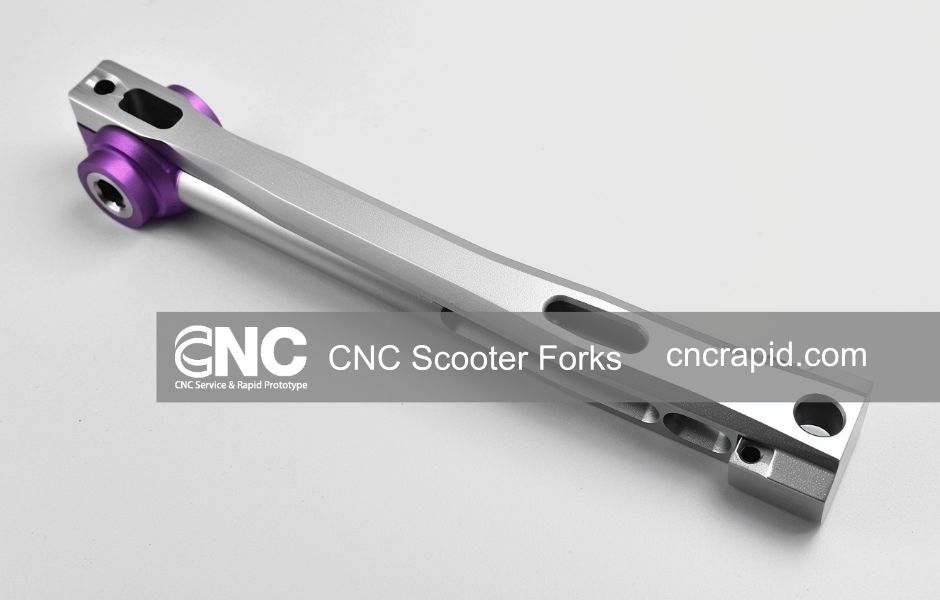

- Customization One of the biggest advantages of CNC machining is the ability to customize parts. Riders can have components designed to their exact specifications, allowing for personalized modifications that enhance both performance and aesthetics.

- Consistent Quality Since CNC machining is an automated process, it eliminates human error, ensuring consistent quality across all parts. This reliability is crucial for maintaining the safety and performance of the motorcycle.

|

|

Popular CNC Machined Motorcycle Parts

Several motorcycle components can be CNC machined to improve performance and durability. Some of the most popular CNC machined motorcycle parts include:

- Brake Calipers High-performance brake calipers can be CNC machined to provide better stopping power and heat dissipation, enhancing safety and control.

- Engine Parts CNC machined engine components, such as pistons and cylinder heads, can be optimized for better combustion efficiency and power output.

- Suspension Components Precision-machined suspension parts, like fork tubes and shock absorbers, offer improved handling and ride comfort.

- Foot Pegs and Handlebars Custom CNC machined foot pegs and handlebars provide a better grip and control, tailored to the rider’s preferences.

|

|

CNC Rapid: Your Partner in Motorcycle Prototyping

At CNC Rapid, we specialize in producing high-quality CNC machined motorcycle parts, and we also offer the capability to create motorcycle prototypes. Whether you have a new design or an innovative concept, we can bring your vision to life with precision and speed. Our state-of-the-art machinery and experienced team ensure that your prototypes meet the highest standards, allowing you to test and refine your ideas before moving to full-scale production.

|

|

Why CNC Machined Motorcycle Parts Are the Future

The future of motorcycle parts lies in precision, customization, and durability, all of which are hallmarks of CNC machining. As technology advances, CNC machining becomes more accessible, allowing more riders to benefit from its advantages. Here are a few reasons why CNC machined motorcycle parts are set to dominate the market:

- Technological Advancements With continuous improvements in CNC technology, the precision and capabilities of machining are constantly evolving, leading to even better and more innovative motorcycle parts.

- Growing Demand for Customization Modern riders increasingly seek unique, personalized components that enhance both performance and aesthetics. CNC machining caters to this demand, providing bespoke parts that mass production cannot match.

- Sustainability CNC machining is a more sustainable manufacturing method, as it reduces material waste and energy consumption compared to traditional processes. This makes it an eco-friendly choice for the environmentally conscious rider.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!