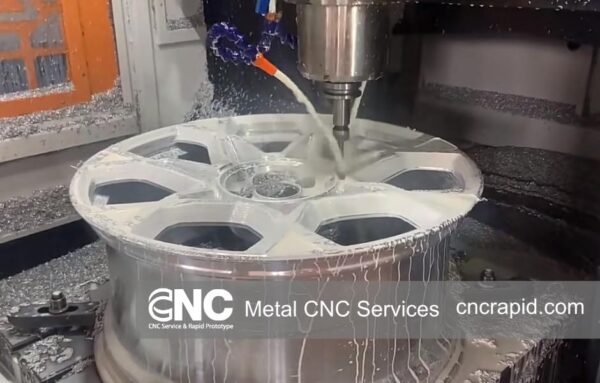

CNC motorcycle wheels lead the way in motorcycle design and engineering, using the unmatched precision of Computer Numerical Control machining. This advanced manufacturing method uses computer programs to control machine tools, making sure the results are highly accurate and consistent. It changes raw materials like metals into finished products that meet specific requirements, have detailed designs, and high-quality finishes. Using CNC machining to make motorcycle wheels shows a commitment to the best quality, giving riders not only better performance but also a chance to make their bikes look unique.

|

|

|

What is CNC Machining?

CNC machining is a key part of modern manufacturing, driven by digital instructions from a computer-aided design (CAD) file. Unlike manual control, which needs operators to start and guide the machine tools’ commands, CNC uses computers to do the cutting and shaping of materials. This automatic process allows for very precise, repeatable results and complex details that manual methods can’t achieve. It’s especially good for making parts with complex shapes, like motorcycle wheels, which need high accuracy and consistency.

Why Choose CNC for Motorcycle Wheels?

Choosing CNC for motorcycle wheels is a smart choice for several important reasons:

- Precision and Quality: CNC machining provides unmatched precision, which is crucial for the balance, performance, and safety of motorcycle wheels. Even a small mistake can cause performance issues or safety risks. CNC makes sure every wheel meets strict standards for a perfect ride.

- Customization: A big benefit of CNC machining is its ability to create custom designs. Many motorcycle fans want their bikes to stand out, and CNC-machined wheels can have unique patterns, shapes, and sizes made just for them.

- Material Flexibility: CNC machines can work with many materials, from aluminum to carbon fiber. This lets manufacturers try different materials to find the right mix of weight, durability, and performance.

- Efficiency and Speed: Even with complex work, CNC machining can make motorcycle wheels fairly quickly. This is good for both manufacturers and buyers, cutting down on waiting times and allowing for faster updates to products.

- Durability: Wheels made with CNC machining tend to last longer. The careful control over how material is removed and shaped makes sure the wheel’s structure stays strong, leading to a longer life and better performance in different riding conditions.

CNC motorcycle wheels mix technology and creativity, improving motorcycle performance and design. Choosing CNC machining for their production shows a move towards more precise engineering, where every detail is important. For riders, this means wheels that perform well and look unique, making both the look and feel of riding a motorcycle better. As technology gets better, CNC’s role in making motorcycle wheels will grow even more, leading to more innovation and customization in motorcycle design.

Why Choose CNC Rapid?

At CNC Rapid, we stand at the cutting edge of precision engineering, offering advanced CNC machining services tailored for motorcycle wheels and beyond. Our expertise and advanced technology enable us to deliver custom solutions that meet the highest standards of quality and performance. Whether you’re seeking to enhance your motorcycle with bespoke wheels or explore other precision-engineered parts, CNC Rapid is your trusted partner for all your CNC machining needs. Let us help bring your vision to life with unparalleled precision and craftsmanship.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!