The quest for sleek designs, precision engineering, and rapid innovation in personal electronic devices is unending. Smartphones, tablets, wearables, and a myriad of other gadgets have become indispensable in our daily lives. Central to the creation of these sophisticated devices is a manufacturing process known for its precision and versatility: CNC (Computer Numerical Control) machining.

|

|

Through its precision, material versatility, speed, and support for innovation, CNC machining not only realizes the vision of designers but also meets the ever-evolving expectations of consumers. As we look to the future, the role of CNC machining in the electronics industry is set to grow, heralding a new era of device manufacturing that is more efficient, sustainable, and bound by no limits of creativity.

|

|

The Essence of CNC Machining in Electronics

CNC machining is a subtractive manufacturing process where computer software dictates the movement of factory tools and machinery. This technology allows for the creation of parts with a degree of precision and efficiency that manual processes cannot match. But what makes CNC machining so indispensable to the production of personal electronic devices?

Precision and Complexity

The compact and intricate nature of personal electronic devices demands exceptional precision. CNC machining meets this requirement by accurately producing components with tight tolerances. The complexity of parts, including the minute ports on a smartphone or the delicate clasps on a smartwatch, can be meticulously crafted to exact specifications. This precision ensures that every device functions seamlessly and meets the high aesthetic standards consumers have come to expect.

Material Versatility

Personal electronic devices utilize a wide range of materials, from metals like aluminum and stainless steel for frames and casings, to plastics and composites for various components. CNC machining’s ability to work with such a diverse array of materials makes it a cornerstone in the manufacturing process. It enables designers to choose the optimal material for each component based on its properties, such as weight, durability, and conductivity, further pushing the boundaries of device design and functionality.

Speed to Market

In the fast-paced electronics industry, the ability to quickly move from concept to production is crucial. CNC machining accelerates the prototyping phase, allowing for rapid iteration and refinement of designs. This speed and flexibility facilitate a shorter development cycle, enabling manufacturers to launch new devices more quickly and stay competitive in the market.

Customization and Innovation

CNC machining not only supports mass production but also offers unparalleled opportunities for customization. This is particularly relevant for high-end or niche personal electronic devices, where consumers seek differentiation. Additionally, the versatility of CNC machining fosters innovation, allowing manufacturers to experiment with novel designs and features that can set their products apart.

Sustainability

As environmental concerns become more pressing, CNC machining offers a sustainable manufacturing option. Its precision reduces material waste, and the durability of machined parts extends the lifespan of devices, contributing to less electronic waste. Furthermore, the efficiency of CNC machines can lead to lower energy consumption compared to other manufacturing processes.

About CNC Rapid

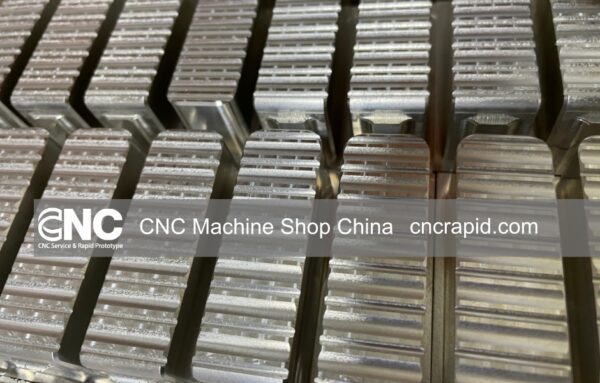

CNC Rapid leverages advanced CNC machining processes known for precision and versatility to meet the exacting demands of the electronics industry.

Our expertise in handling a wide range of materials and our commitment to quality and precision places us as a pivotal partner in producing the personal electronic devices our clients rely on every day. Through our services, we ensure that every component we produce meets the highest standards of quality, functionality, and aesthetic appeal, driving innovation and excellence in the world of personal electronics.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!