In the fast-paced world of product development, rapid prototyping is a game-changer. It allows designers and engineers to quickly create physical models of their designs, test them, and make necessary adjustments. One of the critical components that make rapid prototyping so effective is CNC machining. In this article, we’ll explore why the precision of CNC machining is indispensable in the realm of rapid prototyping.

The Essence of Rapid Prototyping

Rapid prototyping is the process of swiftly creating a physical model of a part or product using three-dimensional computer-aided design (CAD) data. The primary goal is to iterate designs quickly and efficiently, allowing for testing, validation, and refinement before moving into full-scale production.

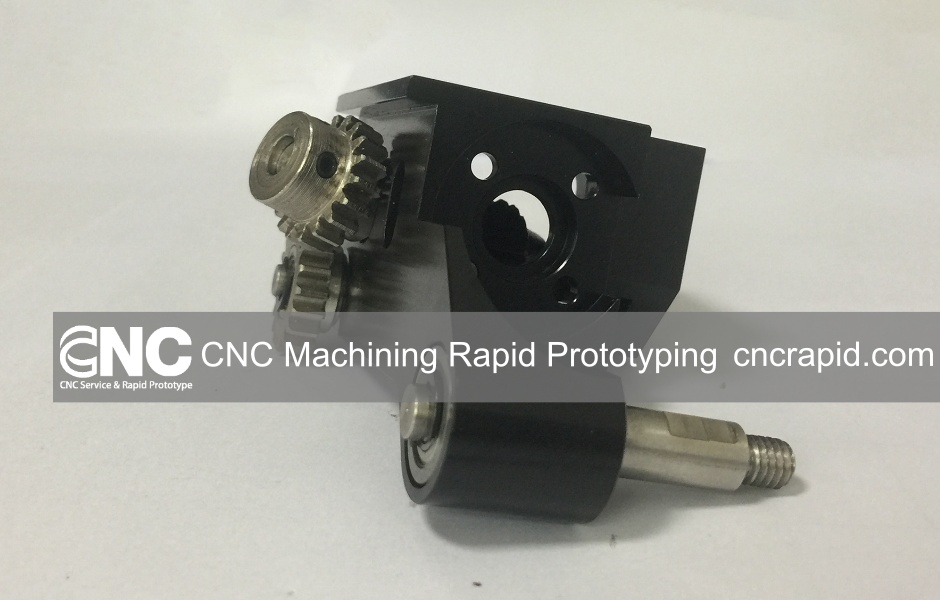

The Role of CNC Machining in Rapid Prototyping

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is removed from a workpiece using cutting tools controlled by a computer. Here’s why it’s crucial for rapid prototyping:

1. Precision and Accuracy

CNC machining offers unparalleled precision. With the ability to produce parts with tight tolerances, it ensures that prototypes accurately represent the final product. This accuracy is essential for detecting design flaws early in the development process.

2. Material Versatility

CNC machining can work with a wide range of materials, including metals, plastics, and composites. This versatility allows for the creation of prototypes that not only look like the final product but also behave similarly in terms of strength, weight, and material properties.

3. Speed and Efficiency

Time is of the essence in product development. CNC machining’s automated nature allows for rapid production of parts with complex geometries that would be time-consuming and difficult to achieve through manual processes.

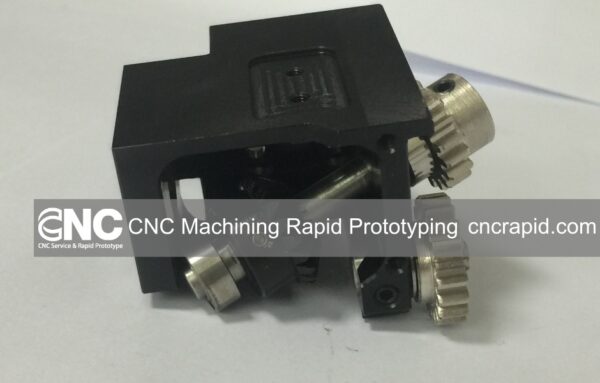

4. Customization and Complexity

CNC machining can easily produce custom and complex shapes. This capability is particularly valuable in prototyping, where designs often undergo multiple iterations and require a high level of customization.

5. Cost-Effectiveness

While 3D printing is often associated with rapid prototyping, CNC machining can be more cost-effective for certain applications, especially when working with metal materials or producing larger quantities of prototypes.

CNC Rapid: Leading the Way in Precision Machining

At CNC Rapid, we understand the importance of precision in rapid prototyping. Our advanced CNC machining services are designed to meet the demanding needs of industries ranging from aerospace to medical devices. With our expertise and commitment to quality, we are your partner in bringing your designs to life with accuracy and efficiency.

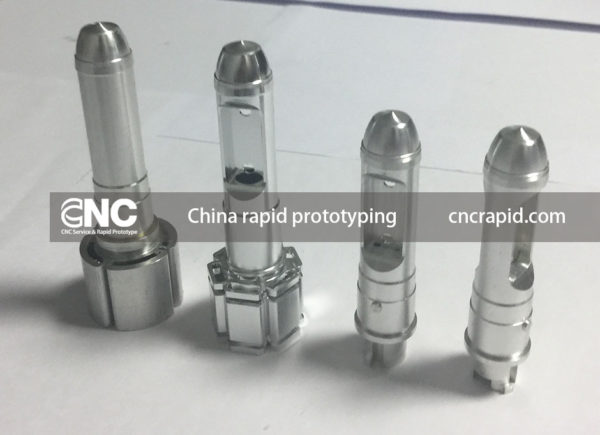

China Rapid Prototype CNC

As a leader in the CNC industry, CNC Rapid has established itself as a go-to destination for rapid prototype CNC services in China. Our cutting-edge facilities and skilled workforce enable us to create prototypes with exceptional precision and speed. Our clients benefit from our ability to work with a diverse range of materials and complex geometries, ensuring that their prototypes are both functional and representative of the final product.

China CNC Machining Service

CNC Rapid is proud to offer comprehensive CNC machining services in China. Our services encompass milling, turning, and grinding, among others. With a commitment to quality and customer satisfaction, we cater to various industries, including automotive, robotics, medical, and consumer electronics. Our advanced equipment and adherence to international standards make us a preferred partner for businesses seeking high-quality CNC machining services.

CNC Milling Aluminum Parts Factory

Aluminum is a material of choice for many industries due to its lightweight and versatile properties. At CNC Rapid, we specialize in CNC milling of aluminum parts. Our factory is equipped with advanced milling machines that can handle both large-scale production and custom, one-off pieces. Whether you need aluminum components for robotics applications or consumer products, our expertise ensures that you receive parts that meet your specifications and exceed your expectations.

CNC Machining Turning Milling Custom Aluminum Parts

In addition to milling, CNC Rapid offers a combination of machining, turning, and milling services for custom aluminum parts. This integrated approach allows us to produce highly complex parts with intricate features. Our engineers work closely with clients to understand their requirements and provide solutions that are both cost-effective and high in quality. From prototyping to final production, our integrated services ensure that your custom aluminum parts are manufactured to the highest standards.

Precision Turned Components Factory

Precision is paramount in manufacturing, and CNC Rapid’s factory is dedicated to producing precision turned components that meet the most stringent tolerances. Our turning capabilities include both CNC and conventional methods, allowing us to produce a wide range of components for various applications. With a focus on quality control and continuous improvement, our precision turned components factory is at the forefront of delivering products that are both high in quality and competitively priced.

Contact CNC Rapid

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!