From prototype to production, rapid CNC production machined parts offer numerous advantages that can significantly enhance manufacturing processes. The speed, precision, cost-effectiveness, and scalability of CNC technology make it an invaluable tool for modern industries. By leveraging rapid CNC production, businesses can streamline their operations, reduce lead times, and deliver high-quality products to market faster than ever before.

What is Rapid CNC Production?

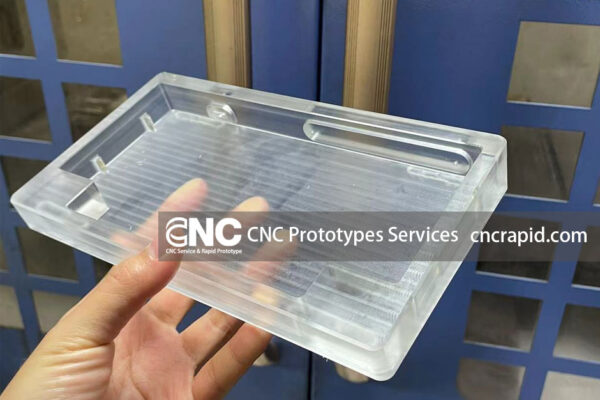

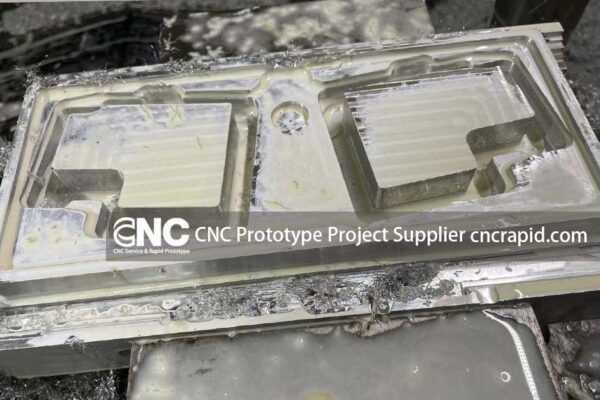

Rapid CNC production involves using advanced computer numerical control machines to quickly and accurately produce parts. These machines are programmed to execute precise cutting, drilling, and milling operations, transforming raw materials into finely machined components. The “rapid” aspect refers to the speed and efficiency with which these machines can produce parts, making it an ideal solution for both prototyping and mass production.

Advantages of Rapid CNC Production Machined Parts

1. Speed and Efficiency

One of the primary advantages of rapid CNC production is its ability to significantly reduce production times. Traditional manufacturing methods can be time-consuming, especially when transitioning from prototype to production. CNC machines can swiftly produce multiple iterations of a prototype, allowing for quick adjustments and refinements. Once the design is finalized, the same machines can seamlessly transition to full-scale production, ensuring a rapid turnaround time.

2. Precision and Consistency

CNC machines are renowned for their precision and consistency. They are capable of producing parts with incredibly tight tolerances, ensuring that each component meets exact specifications. This level of accuracy is essential for industries where even the smallest deviations can lead to significant issues. Whether producing a single prototype or thousands of production parts, CNC machines deliver consistent quality every time.

3. Cost-Effectiveness

Rapid CNC production can also be more cost-effective compared to traditional manufacturing methods. The ability to quickly produce and test prototypes reduces the risk of costly errors during the production phase. Additionally, CNC machines require less manual intervention, reducing labor costs and minimizing the potential for human error. The efficiency of these machines also means that material waste is minimized, further reducing production costs.

4. Flexibility in Material and Design

CNC machines are incredibly versatile, capable of working with a wide range of materials, including metals, plastics, and composites. This flexibility allows manufacturers to choose the best material for their specific application without compromising on quality or performance. Furthermore, CNC machines can easily adapt to complex designs and intricate geometries, making them ideal for producing custom and highly specialized parts.

5. Scalability

One of the key benefits of rapid CNC production is its scalability. Whether you need a single prototype or thousands of production parts, CNC machines can handle varying production volumes with ease. This scalability is particularly advantageous for businesses experiencing fluctuating demand or those looking to quickly scale up production without significant lead times.

Applications of Rapid CNC Production Machined Parts

The advantages of rapid CNC production extend across various industries, including:

• Automotive: Engine components, transmission parts, and custom automotive parts.

• Electronics: Housings, enclosures, and intricate electronic components.

• Medical: Surgical instruments, implants, and medical device components.

• Consumer Products: Prototypes and production parts for household and personal use items.

Why Choose CNC Rapid?

At CNC Rapid, we specialize in providing top-notch CNC machining services tailored to your specific needs. Whether you’re in the initial stages of prototyping or ready for full-scale production, our advanced CNC machines and experienced team are here to help you achieve your manufacturing goals efficiently and effectively. Contact us today to learn more about our rapid CNC production solutions.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!