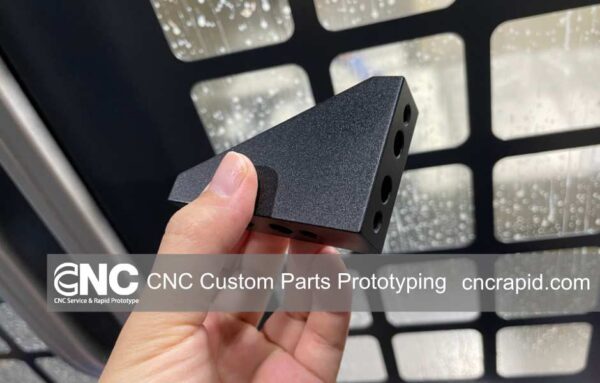

Every product starts as an idea, and the faster that idea becomes a physical part you can hold, test, and refine, the sooner it reaches the market. At CNC Rapid, CNC custom parts prototyping bridges the gap between your 3D model and a flawless first-article sample—often in under a week—without sacrificing the accuracy engineers depend on.

Why Speed Matters More Than Ever

Short development cycles are no longer a luxury reserved for tech giants; they’re necessary for any company competing in 2025. Electronics enclosures, medical fixtures, EV battery trays—each of these projects lives or dies by how quickly prototypes can be evaluated, iterated, and sent back to the shop floor. CNC machining remains the most reliable way to compress that timeline because the process:

- Works directly from your CAD data—no tooling delays

- Cuts almost any engineering material, from 7075-T6 aluminum to PEEK

- Holds tight tolerances on the first run, keeping design intent intact

For teams juggling deadlines and shrinking budgets, speed plus precision equals a genuine competitive edge.

From File Upload to Finished Part: The CNC Rapid Approach

- Instant DFM Check: As soon as your STEP file lands in our queue, an automated Design-for-Manufacturability audit flags undercuts, thin walls, and deep pockets before programming begins. Surprises never reach the machine.

- Live Quote & Material Selection: Pricing, lead time, and material options—food-grade stainless, hard-anodized aluminum, matte-black acetal—appear in one dashboard. Lock them in with a single click.

- Toolpath Optimization: Our programmers blend 3- and 5-axis moves to minimize cycle time while protecting surface finish, often shaving hours off multi-fixture jobs.

- CNC Machining & In-Process QC: Late-model CNC centers run probing cycles that capture real-time inspection data, correcting deviations before they become defects.

- Post-Processing & Finishing: Deburr, tumble, bead-blast, anodize, powder-coat—finishes happen under one roof to avoid extra shipping days. Dimensional reports and finish certificates ship with every order.

- Delivery in as Little as Three Days: International customers typically receive prototypes within five to seven calendar days, door to door; domestic deliveries inside China often arrive even sooner.

Balancing Cost and Precision

Rapid machining can be both fast and affordable when a few best practices guide the design:

- Keep walls above 1 mm to reduce chatter and tool deflection.

- Use standard drill sizes wherever possible; custom reamers add cost.

- Limit ultra-fine surface requirements (Ra < 0.4 µm) to functional areas only.

Applying these rules early can trim 20–30 % off prototype budgets without compromising function.

Popular Materials for CNC Custom Parts Prototyping

A wide material menu is one of the biggest advantages of CNC Rapid’s CNC custom parts prototyping service.

- Aluminum 6061 – The everyday workhorse for housings, brackets, and fixtures thanks to its strength-to-weight ratio and anodizing friendliness.

- Aluminum 7075 – Higher tensile strength makes it the top pick for aerospace frames and performance-critical drone components.

- Stainless Steel 304 – Corrosion-resistant, food-safe, and ideal for medical jigs or consumer appliances.

- Stainless Steel 316 – Adds molybdenum for even better corrosion and chemical resistance; common in marine hardware and lab equipment.

- Brass C360 – Excellent machinability and a polished aesthetic—often chosen for fluid-control fittings and decorative knobs.

- Copper C110 – High electrical and thermal conductivity; perfect for bus bars, heat sinks, and EMI shields.

- Titanium Grade 5 (Ti-6Al-4V) – A premium alloy where weight and exceptional strength both matter—implants, motorsport parts, and satellite brackets.

- POM (Acetal/Delrin) – Low-friction engineering plastic used in gears, bearings, and snap-fit assemblies.

- ABS – Affordable, impact-resistant plastic that bridges prototype and end-use parts in consumer electronics.

- PEEK – High-temperature, chemical-resistant polymer for aerospace inserts and medical devices sterilized in autoclaves.

Beyond the Prototype: Path to Low-Volume Production

A robust CNC workflow scales smoothly from one piece to a hundred without retooling. Once geometry and tolerances are locked, repeat runs avoid the re-quote delay common with other suppliers. Many clients leverage this bridge-production window while injection-mold tooling is built or die-cast suppliers ramp up.

Sustainability Through Precision

Material waste is a hidden cost in every prototype budget. Tight toolpaths, shorter setups, and accurate first passes mean less scrap metal heading to recycling. With rising aluminum and stainless prices, the savings are felt in both wallet and carbon footprint.

Contact CNC Rapid Today

Whether you’re refining a medical implant or launching the next smart-home gadget, CNC Rapid’s CNC custom parts prototyping keeps momentum on your side. Turning a fresh CAD concept into a functional sample in days—not weeks—means earlier testing, faster learning, and products that beat competitors to market.

Ready to accelerate your next project? Upload your files to CNC Rapid today and see how quickly ideas become reality.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!