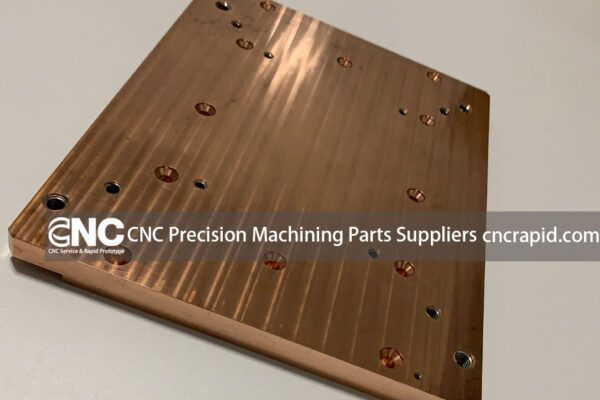

Copper CNC Machining Services are an essential resource for industries that require precision, accuracy, and consistency in the manufacturing of copper parts. Copper, a soft, ductile metal with high thermal and electrical conductivity, is a popular choice for a wide range of applications, including electrical components, mechanical parts, and plumbing fixtures. However, CNC machining copper presents some unique challenges and considerations, including the need for specialized cutting tools and regular tool maintenance.

One of the key benefits of CNC Machining Services is their ability to produce precise and repeatable parts. CNC machining is a computer-controlled manufacturing process that uses cutting tools to shape and finish materials with high levels of precision and repeatability. This allows manufacturers to produce complex shapes and features, such as holes, slots, and contours, with a high degree of accuracy and consistency. In addition, CNC machining allows manufacturers to easily make changes and adjustments to the design of a part, reducing the need for expensive and time-consuming prototyping and testing.

Another advantage of CNC Machining Services is their ability to produce high-quality parts with a smooth and consistent finish. CNC machining uses cutting tools that are carefully designed and maintained to produce a clean and uniform surface finish on the material. This can be particularly important for applications that require electrical conductivity, as a smooth and consistent surface is essential for good conductivity. In addition, a high-quality finish can improve the appearance and durability of the part, making it more aesthetically pleasing and longer-lasting.

Copper CNC Machining Services are widely used in a variety of industries, including electronics, aerospace, medical, and automotive. In the electronics industry, copper is a key material for the manufacture of printed circuit boards, connectors, and other electrical components. In the aerospace industry, copper is used in the production of aircraft engine parts, fuel lines, and electrical wiring. In the medical industry, copper is commonly used for the production of surgical instruments, prosthetics, and medical devices. And in the automotive industry, copper is used for the manufacture of brake lines, radiators, and other mechanical components.

Copper CNC Machining Services provide an efficient and reliable way to produce high-quality copper parts for a wide range of applications. With their ability to produce precise and repeatable parts, Copper CNC Machining Services are an essential resource for industries that rely on the unique properties of copper.

At DFM Rapid, we are a leading provider of Copper CNC Machining Services, with over 10 years of experience in the industry. Our team of skilled and experienced machinists uses our CNC machines and cutting-edge technology to produce high-quality copper parts for our clients. We offer a full range of Copper CNC Machining Services, including milling, turning, and drilling, and we are committed to providing our clients with the best value and service in the industry.

If you are in need of Copper CNC Machining Services, please contact us at [email protected]. We would be happy to provide you with a free quote and discuss how our services can meet your needs. We look forward to working with you and helping you produce the high-quality copper parts you need for your business or project.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!