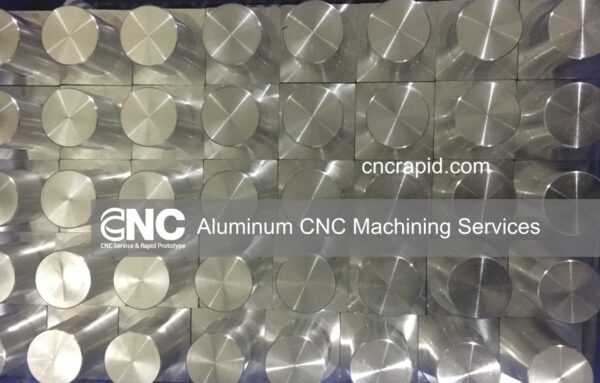

At CNC Rapid, we specialize in delivering CNC Turn-Mill Parts that combine the best of turning and milling processes to create high-quality custom components for a variety of industries. Our advanced turn-mill machines allow us to machine complex parts with precision, efficiency, and consistency, all from a single setup.

What is CNC Turn-Mill Machining?

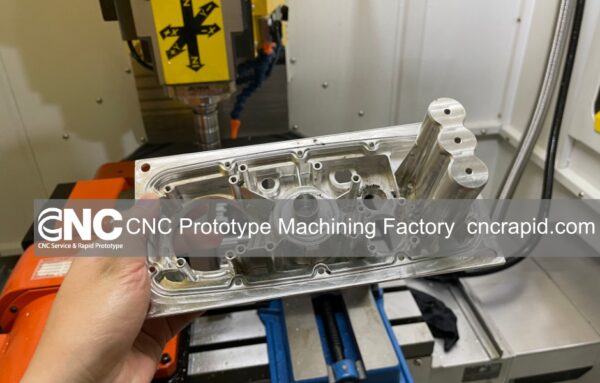

CNC Turn-Mill Machining is an advanced manufacturing process that integrates both turning and milling operations in one machine. This hybrid machining technology allows for the simultaneous execution of both processes, significantly reducing production time and improving the precision of complex geometries. In traditional machining, parts would need to be transferred between different machines, but with turn-mill technology, everything is done in one go, increasing efficiency and maintaining accuracy throughout the production.

Advantages of CNC Turn-Mill Parts

1. Precision and Accuracy

The integration of turning and milling in a single setup ensures that parts are machined with high precision and accuracy. Multi-axis CNC turn-mill machines are capable of achieving tight tolerances, which is crucial for industries that require exacting standards, such as aerospace, automotive, and electronics.

2. Efficiency and Cost-Effectiveness

CNC turn-mill machining allows for the production of complex parts in fewer steps, reducing the time it takes to machine each part. This efficiency translates to cost savings for our clients, as the need for multiple setups and machine transfers is eliminated. The streamlined process also reduces the risk of errors, ensuring that each part is manufactured to the highest standards of quality.

3. Versatility in Material and Design

Our turn-mill machines are capable of handling a wide range of materials, from metals like aluminum, steel, and titanium to various plastics. Whether you need custom parts for medical devices, electronics, or industrial machinery, CNC Rapid has the expertise to machine components that meet your design specifications and material requirements.

4. Reduced Lead Times

Because turn-mill machining reduces the number of setups required, production lead times are significantly shortened. This is particularly beneficial for projects that require fast turnaround times without sacrificing quality. CNC Rapid’s ability to produce custom parts efficiently means that we can meet tight deadlines while maintaining the precision you expect.

Applications of CNC Turn-Mill Parts

CNC turn-mill parts are used across a wide variety of industries, where precision, durability, and complexity are critical. Some common applications include:

- Automotive: High-precision engine components, shafts, and connectors.

- Aerospace: Complex geometries for flight control systems and structural components.

- Medical Devices: Precision parts for surgical tools and diagnostic equipment.

- Electronics: Custom enclosures, brackets, and connectors for high-performance devices.

- Industrial Machinery: Heavy-duty components requiring strength and durability.

Why Choose CNC Rapid for CNC Turn-Mill Parts?

At CNC Rapid, we bring years of experience in custom machining to the table, and our advanced turn-mill machines are capable of producing high-quality parts with precision and efficiency. Our skilled team of engineers and machinists work closely with clients to ensure that every part meets their exact specifications, whether it’s a small batch of prototypes or large-scale production.

1. Advanced Turn-Mill Technology

Our advanced turn-mill machines are equipped with multi-axis capabilities, allowing us to handle even the most complex part designs with ease. This technology enables us to offer more efficient machining solutions, especially for parts that require intricate detailing and tight tolerances.

2. Custom Machining Solutions

Every project we take on is unique, and we are committed to delivering custom solutions that align with the specific needs of our clients. From material selection to surface finishes, we work closely with you to ensure that every aspect of your project is handled with precision and care.

3. Commitment to Quality

Quality is at the heart of everything we do at CNC Rapid. Every part we machine undergoes rigorous inspection to ensure that it meets the highest industry standards for precision and durability. Our commitment to quality extends beyond the machining process — we ensure that every part is delivered on time and ready to perform in its intended application.

Let CNC Rapid be your trusted partner

CNC Rapid is your trusted partner for high-precision CNC Turn-Mill Parts. With our advanced machining capabilities, experienced team, and commitment to quality, we deliver custom solutions that meet the unique requirements of your industry. Whether you need prototypes or full-scale production runs, we are ready to help you bring your project to life with precision and efficiency.

Contact CNC Rapid Today!

If you’re looking for a reliable partner for CNC Turn-Mill Parts, contact CNC Rapid today. Our team of experts is ready to assist you with tailored machining solutions that meet your exact needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s machining services.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!