Choosing the right CNC prototype machining factory is a decision that can significantly impact the quality and success of your project. With the increasing demand for precision and speed, choosing the right CNC prototype machining factory is crucial for the success of your project. Here are some key factors to consider when making your choice:

Experience and Expertise

- Look for a factory with a proven track record in CNC machining. Their years in the industry can be a testament to their expertise and reliability.

- Check if they have experience with the specific material and design you require. Different materials may require different machining techniques.

Advanced Technology and Equipment

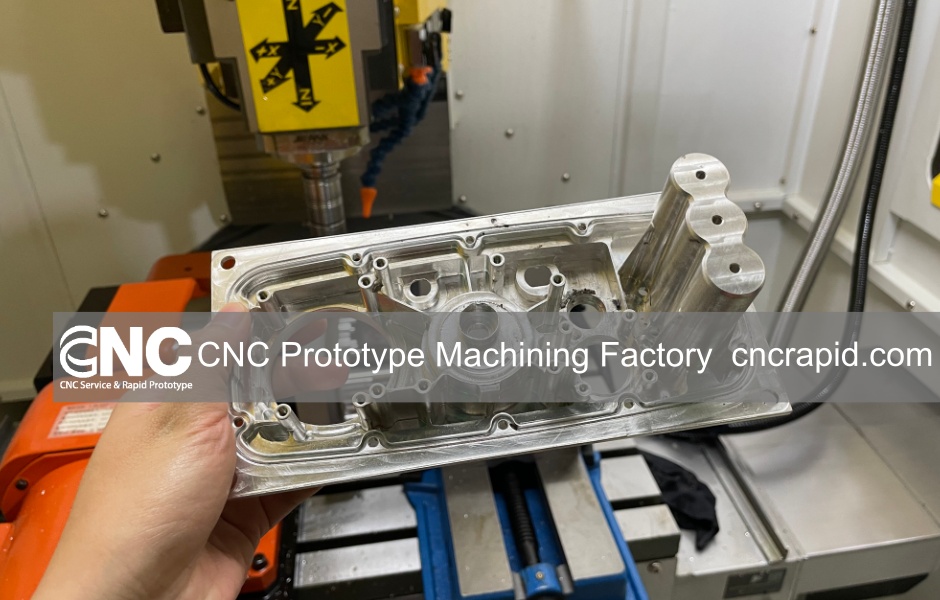

- Ensure the factory uses the latest CNC machines and software. This ensures precision, efficiency, and consistency in the prototypes.

- Ask about their maintenance schedule. Regular maintenance of machines is vital for optimal performance.

Quality Control

- A reputable factory will have stringent quality control measures in place. This ensures that every prototype meets the required standards.

- Check if they have certifications from recognized industry bodies, which can be an indicator of their commitment to quality.

Turnaround Time

- Time is often of the essence in prototyping. Ask about their lead times and ensure they can meet your deadlines.

- A factory with in-house design and engineering teams can often speed up the prototyping process.

Customer Service and Communication

- Effective communication is key to ensuring your requirements are met. Choose a factory that is responsive and open to feedback.

- Look for reviews or testimonials from previous clients to gauge their customer service quality.

Cost-Effectiveness

- While cost shouldn’t be the only factor, it’s essential to ensure you’re getting value for your money.

- Ask for a detailed quote and ensure there are no hidden charges. Compare quotes from different factories to get a sense of the market rate.

Confidentiality

- If your prototype is for a new and innovative product, ensure the factory has measures in place to protect your intellectual property.

- A non-disclosure agreement (NDA) can be a good way to safeguard your design and idea.

Location

- While many businesses opt for overseas factories due to cost savings, consider the benefits of choosing a local factory, such as easier communication, faster shipping, and the possibility of in-person visit

Why Choose CNC Rapid

CNC Rapid is more than just a CNC machining service provider. Established as a leader in the industry, CNC Rapid prides itself on being at the forefront of precision, efficiency, and speed. With a commitment to unparalleled service, CNC Rapid offers a range of services from rapid prototyping to high-volume production. The company’s dedication to excellence is evident in its track record, with numerous satisfied clients and successful projects under its belt. When you choose CNC Rapid, you’re not just opting for a service; you’re investing in a partnership that prioritizes your project’s success.

1. Understanding the Importance of Precision

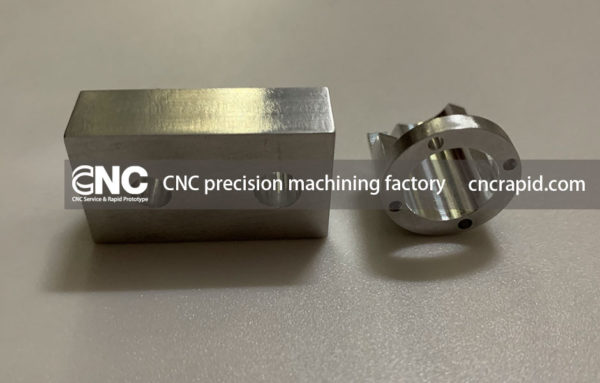

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to carve out desired shapes from solid blocks of material. The precision of this process is paramount, as even the smallest tolerances can make a significant difference in the final product. When choosing a CNC factory, ensure they prioritize accuracy and have a track record of delivering high-precision parts.

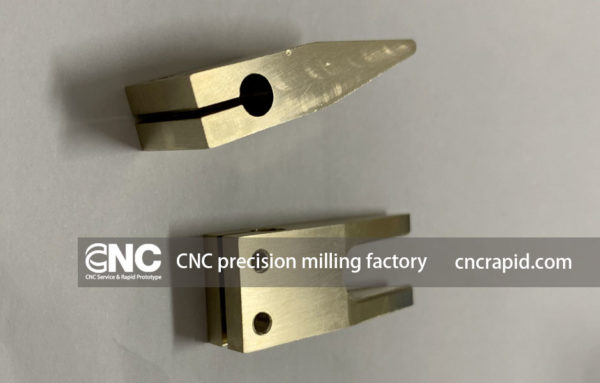

2. Versatility in Material Handling

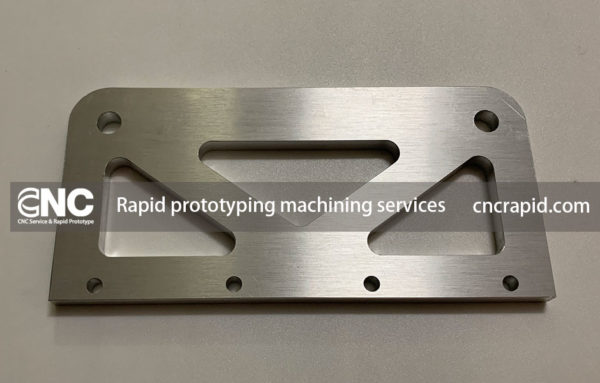

Different projects require different materials. Aluminum, for instance, is known for its lightweight nature and excellent machinability. A top-notch CNC factory should have a deep understanding of various materials and the right machining techniques to unlock their full potential. CNC Rapid, for example, has expertise in aluminum CNC machining, ensuring optimal results for clients.

3. From Prototype to Production

The journey from a prototype to a final product can be intricate. It’s crucial to choose a CNC factory that can seamlessly handle both rapid prototyping and high-volume production. CNC Rapid stands out in this regard, offering a wide range of services from prototype to production.

4. Reputation and Reliability

In a sea of CNC service providers, especially in manufacturing hubs like China, reputation matters. CNC Rapid has established itself as a leading provider of CNC machining services in China, known for its high quality, fast turnaround times, and exceptional customer service.

5. Get a Quote and Start Your Journey

Before finalizing your decision, it’s always a good idea to get a quote and understand the cost implications. CNC Rapid offers a straightforward quote process, ensuring transparency and clarity for clients.

Choosing the right CNC prototype machining factory is a decision that can significantly impact the quality and success of your projects. By prioritizing precision, versatility, production capabilities, and reputation, you can make an informed choice. CNC Rapid, with its commitment to excellence and a proven track record, is poised to be your trusted partner in this journey.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!