CNC machine shops are a critical part of the manufacturing industry. These shops, equipped with cutting-edge technology, play a critical role in the production of intricate components essential for various industries. Whether you are a seasoned engineer, a manufacturer, or someone just dipping your toes into the world of CNC machining, this ultimate guide will unlock the secrets of precision manufacturing through CNC machine shops.

What is a CNC Machine Shop?:

CNC, or Computer Numerical Control, is a process used in the manufacturing sector that involves the use of computers to control machine tools. A CNC machine shop is a facility where these computer-controlled machines are used to produce precision parts and components.

Why CNC Machining?:

- Precision: CNC machines can produce highly accurate parts, down to the micrometer.

- Scalability: Ideal for both small and large production runs.

- Complexity: Ability to produce complex shapes that would be almost impossible to achieve manually.

- Consistency: Ensures that each part is identical to the specifications.

- Cost-Effective: Reduces labor costs and minimizes waste.

Applications of CNC Machining:

From robotics to healthcare, CNC machining is indispensable. Here are some industries where CNC machining shines:

- Robotics: For producing robotic components and assemblies.

- Automotive: In manufacturing car parts.

- Medical: For creating surgical instruments and implants.

- Construction: In the fabrication of heavy equipment.

- Consumer Electronics: For producing parts like casings and circuit boards.

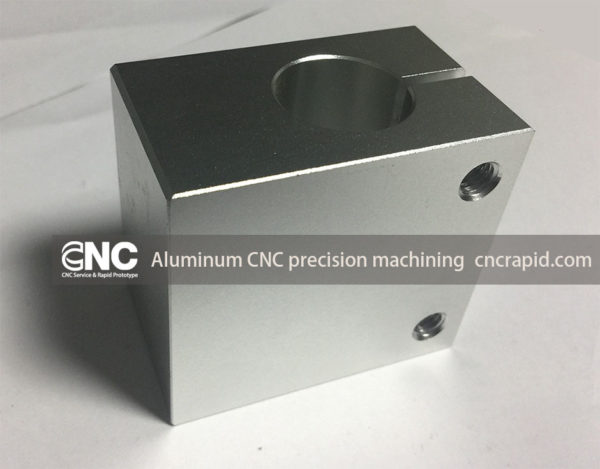

Aluminum CNC Precision Machining:

Aluminum is a popular material in CNC machining due to its lightweight and excellent machinability. CNC machine shops use high-precision tools to create complex aluminum parts with tight tolerances. These parts are used in industries such as aerospace, automotive, and robotics for their strength and corrosion resistance.

When sourcing CNC machined parts, it’s crucial to choose a reliable supplier. Look for suppliers with a wide range of materials and capabilities, as well as a commitment to quality and customer service. Suppliers like CNC Rapid offer a diverse range of CNC machined parts tailored to meet the specific needs of various industries.

CNC Machined Components Manufacturers:

Manufacturers specializing in CNC machined components often have expertise in producing high-precision parts for specialized applications. When selecting a manufacturer, consider factors such as technological capabilities, quality control processes, and industry certifications.

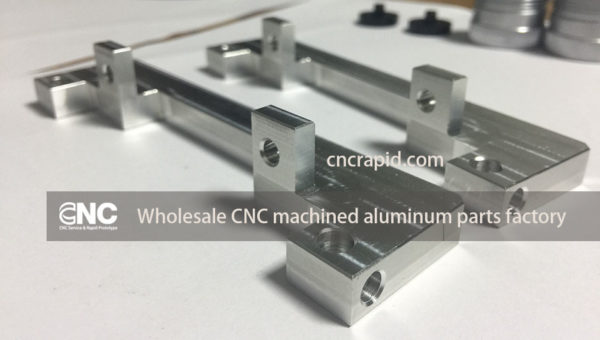

CNC Machined Aluminum Parts Factory:

A CNC machined aluminum parts factory specializes in the production of aluminum components. These factories often have advanced CNC machines capable of high-speed machining, which is essential for working with aluminum. When choosing a factory, consider the scale of production, lead times, and the range of aluminum alloys they can work with.

Before moving to full-scale production, it’s often necessary to create prototypes. CNC machine shops offer prototype machining services to produce small quantities of parts for testing and validation. These services are essential for product development, allowing designers and engineers to identify and correct issues before committing to large production runs.

Choosing the Right CNC Machine Shop:

- Experience and Expertise: Look for a shop with a proven track record.

- Technology: Ensure they have the latest CNC machines and software.

- Quality Control: Check if they adhere to quality standards like ISO.

- Customer Service: Gauge their responsiveness and willingness to meet your needs.

- Pricing: Compare quotes but remember that the cheapest option is not always the best.

The Future of CNC Machining:

With advancements in technology, CNC machining is evolving. The integration of AI, IoT, and automation is set to revolutionize how CNC machine shops operate.

Why CNC Rapid?

CNC machine shops are the backbone of modern manufacturing. With their ability to produce high-precision components at scale, they are indispensable in today’s fast-paced world. Whether you are looking to partner with a CNC machine shop or just fascinated by the technology, understanding the intricacies of CNC machining is essential. This guide has provided you with the knowledge to unlock the world of precision manufacturing through CNC machine shops.

Are you looking for a CNC machine shop that guarantees precision, efficiency, and quality? At CNC Rapid, we combine cutting-edge technology with expertise to deliver unparalleled CNC machining services. Contact us today to bring your manufacturing vision to life.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!