As industries evolve in 2026, the demand for high-precision, reliable, and efficient manufacturing processes has never been greater. At CNC Rapid, we are proud to be a leading provider of Aluminum CNC Milling Services, helping businesses across the globe achieve their production goals with unmatched quality and precision.

Why Choose Aluminum CNC Milling in 2026?

Aluminum remains one of the most versatile and widely used materials in manufacturing due to its lightweight properties, excellent strength-to-weight ratio, and corrosion resistance. CNC milling enhances these benefits by enabling:

- High Precision: Achieve tight tolerances and intricate designs with ease.

- Efficient Production: Streamline the manufacturing process for faster turnaround times.

- Material Versatility: Support for various aluminum grades, including 6061, 7075, and more.

- Cost-Effectiveness: Minimized material waste and optimized production costs.

In 2026, businesses are turning to CNC Rapid for their Aluminum CNC Milling Service needs, leveraging our advanced technology and expertise to stay ahead in competitive markets.

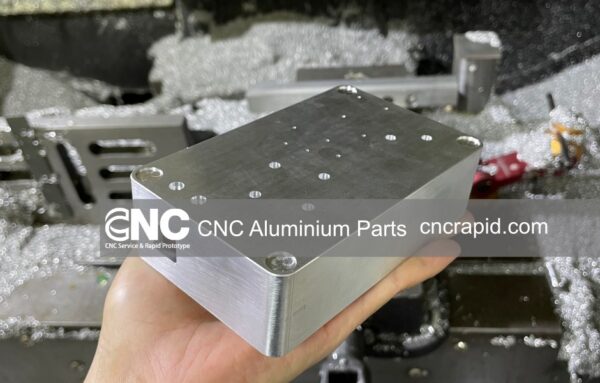

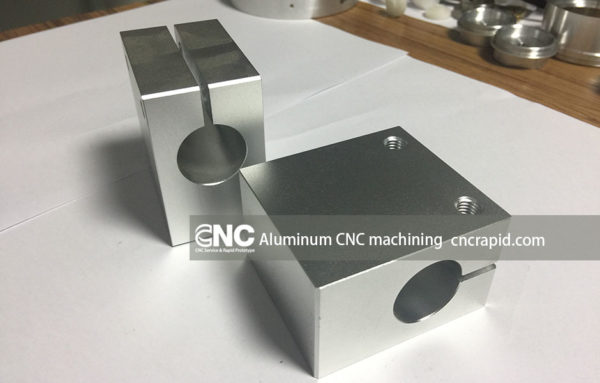

Aluminum CNC milling is a process that uses a computer-controlled machine to cut aluminum parts. The machine uses a cutting tool to remove material from the aluminum block, leaving behind the desired shape.

Aluminum CNC milling is a precise process that can produce high-quality parts. The process can also be used to create complex parts that would be difficult to make using traditional machining methods.

Aluminum CNC milling service in China. Precision machined aluminum parts are becoming a choice for many industries. Aluminum is one of the popular materials due to its excellent mechanical properties. These include affordability, softness, durability, and corrosion resistance.

CNC machining is a practical option for everything from prototype manufacturing to production runs. We are a one-stop shop for custom machining and manufacturing.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Aluminum CNC Machining Services

We manufacture various aluminum parts through the following processes:

- Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts.

- CNC Milling and Turning: We have equipment with 3 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc.

- Production Wire EDM: We produce high precision machine parts using 3 axis wire EDM.

Aluminum CNC machining services in China

The Role of Aluminum CNC Milling Across Industries

As industries embrace innovation in 2025, Aluminum CNC Milling Services are crucial in supporting advancements across sectors:

- Renewable Energy: Custom parts for solar panels and wind turbines.

- Medical Devices: Precision-engineered components for critical applications.

- Robotics: Durable parts for automation and robotics systems.

Get in Touch

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!