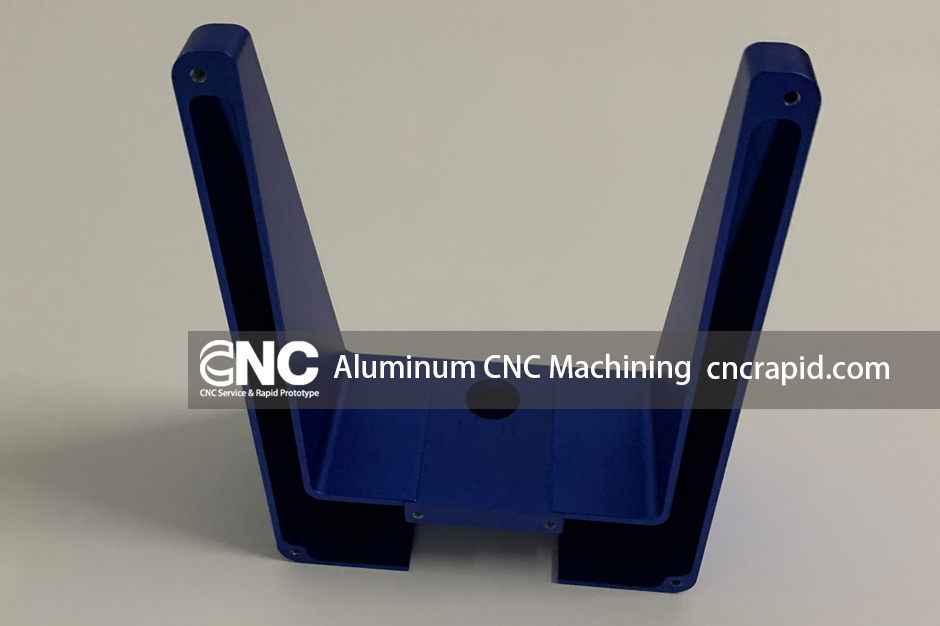

Aluminum is a versatile material that is widely used in many different industries, including aerospace, automotive, electronics, and medical devices. It’s lightweight, durable, and has excellent thermal and electrical conductivity, making it an ideal choice for a wide range of applications.

To produce high-precision aluminum parts and components, CNC machining has become a popular method in recent years. CNC machining uses computer software and automated machinery to precisely cut, shape, and form metal parts according to exact specifications.

Advantages of Aluminum CNC machining

- High Precision: CNC machines can achieve very tight tolerances, making them ideal for producing parts with intricate designs and precise specifications.

- Consistent Quality: CNC machining is a highly automated process that ensures consistent quality across all parts, reducing the risk of errors or defects.

- Cost-Effective: While CNC machining requires an initial investment in equipment and programming, it can be a cost-effective manufacturing method for producing aluminum parts in large quantities.

- Versatility: CNC machines can produce a wide range of shapes and sizes, making them suitable for a variety of applications.

The CNC machining process for aluminum

- Design: The first step in the CNC machining process is to create a 3D model of the aluminum part using computer-aided design (CAD) software.

- Programming: Once the design is complete, the CAD file is imported into the CNC machine’s software. The software generates toolpaths based on the part’s design, which determine the cutting paths that the machine will follow.

- Tool Selection: After programming, the appropriate cutting tools are selected based on the part’s design, material, and desired finish.

- Cutting: With the tools in place, the CNC machine begins cutting the aluminum block or sheet. The cutting process may involve drilling, milling, or turning, depending on the part’s design.

- Finishing: Once the cutting is complete, the aluminum part may require finishing operations, such as deburring or sanding, to achieve the desired surface finish.

Throughout the CNC machining process, the machine’s computer-controlled motors and spindles move the cutting tools along the specified toolpaths with high precision and accuracy. This automation ensures that the finished aluminum parts meet the design specifications and tolerances precisely.

Aluminum CNC machining is a highly effective and efficient method for producing high-quality parts with exceptional precision and consistency. Despite some limitations and challenges, the benefits of CNC machining for aluminum make it a popular choice for various industries and applications.

When choosing a reliable aluminum CNC machining service provider, it’s important to consider their certifications, capabilities, quality control measures, experience, and communication. By selecting a reputable service provider, you can ensure that your parts are produced to the highest standards of quality and accuracy.

Thank you for reading our blog on the top benefits of using aluminum CNC machining for your project. At DFM Rapid, we are proud to offer high-quality aluminum CNC machining services to meet your project needs. Our team of experienced professionals is dedicated to providing precision, consistency, and cost-effectiveness in every project we undertake. With advanced equipment and rigorous quality control measures, we ensure that our aluminum parts meet the highest standards of quality and performance. Contact us today to learn more about how we can help bring your project to life with our aluminum CNC machining services.

Contact us

If you need Metal & Plastic CNC Machining Parts for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!