At CNC Rapid, we specialize in precision CNC machining and professional surface finishing services for custom aluminum parts. One of the most popular finishing methods is anodizing, a process that improves the durability, corrosion resistance, and appearance of aluminum components.

What is Anodizing?

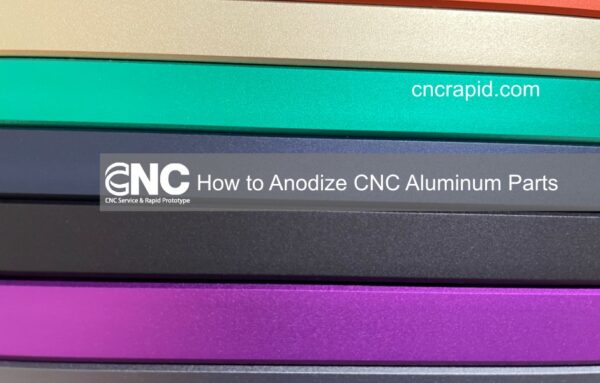

Anodizing is an electrochemical process that converts the surface of aluminum into a tough, protective, and corrosion-resistant oxide layer. It also allows for coloring the surface in a wide range of finishes, including black, clear (natural), gold, red, and more.

Benefits of anodizing:

-

Improved corrosion resistance

-

Increased surface hardness

-

Enhanced aesthetics and color options

-

Better wear resistance

-

Electrical insulation

Black Anodized CNC Aluminum Part

This custom CNC machined aluminum part has been anodized in matte black, giving it a clean, professional look. Black anodizing is often used in consumer electronics, robotics, and enclosures where a sleek, non-reflective finish is desired. The surface is smooth, uniform, and resistant to wear and corrosion.

Natural (Clear) Anodized CNC Aluminum Part

The second part features a natural anodized finish, which maintains the metallic silver appearance of the aluminum while adding a fine, matte texture. This is an ideal choice for parts used in industrial applications, precision equipment, or environments where a clean, neutral aesthetic is preferred.

Recommended Aluminum Alloys for Anodizing

Not all aluminum grades are equally suited for anodizing. Here are some commonly used alloys and their characteristics:

| Alloy | Description | Anodizing Performance |

|---|---|---|

| 6061-T6 | High strength, good machinability, widely used | Excellent – uniform finish and strong anodized layer |

| 7075-T6 | Very strong, used in aerospace | Fair – may show uneven color, better with hard anodizing |

| 5052 | Corrosion-resistant, good for marine parts | Good – less decorative but functional |

| 2024 | High strength, poor corrosion resistance | Not ideal for decorative anodizing, best for hard anodizing |

At CNC Rapid, we primarily work with 6061-T6 aluminum, which offers a great balance between machinability, strength, and anodizing performance.

CNC Machining Process Before Anodizing

Before any aluminum part can be anodized, it must go through a precise CNC machining process. Here’s a quick overview of our standard workflow:

-

Material Selection & Cutting

Choose the appropriate aluminum alloy and cut raw stock to size. -

CAM Programming

Generate CNC toolpaths based on 2D drawings or 3D models. -

Rough Machining

Remove bulk material to form the basic shape of the part. -

Finishing Passes

Achieve final dimensions, smooth surfaces, and tight tolerances. -

Deburring & Cleaning

Remove sharp edges and contaminants to prepare the part for anodizing. -

Anodizing

Parts are sent for anodizing to enhance durability and appearance.

Work With CNC Rapid

Whether you need black anodized parts for sleek product designs or natural anodized parts for clean, functional components, CNC Rapid is here to help.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!