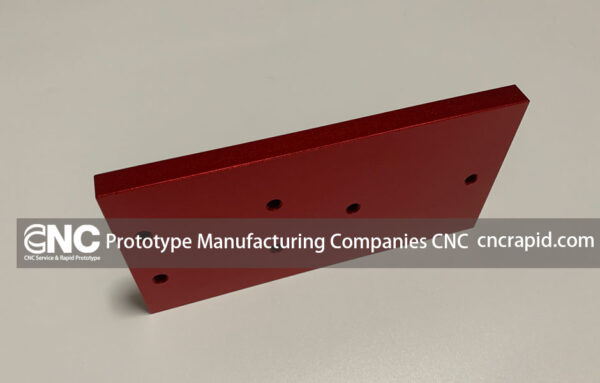

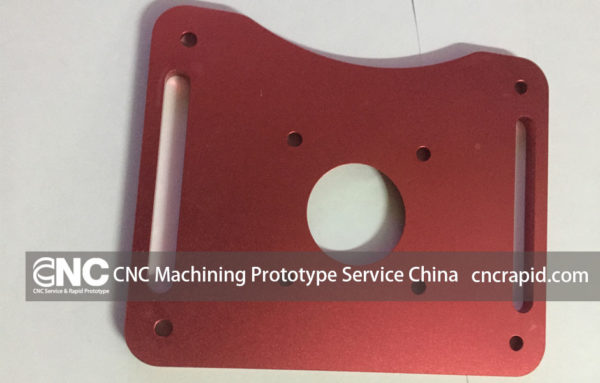

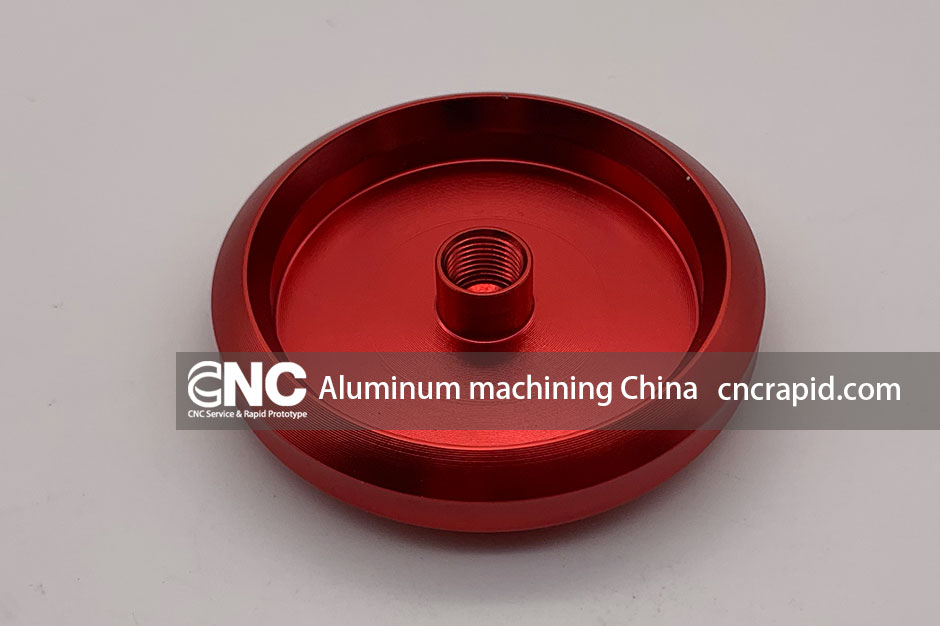

Precision manufacturing and CNC machining are closely linked, with the latter being known for producing parts with high accuracy and consistency. At CNC Rapid, we specialize in using this technology to its fullest, particularly in the machining of aluminum parts. One of the most visually striking and technically advantageous finishes we offer is red anodized aluminium. This article aims to shed light on the benefits and applications of red anodized aluminium CNC machining parts, helping our clients navigate the complexities of our industry.

|

|

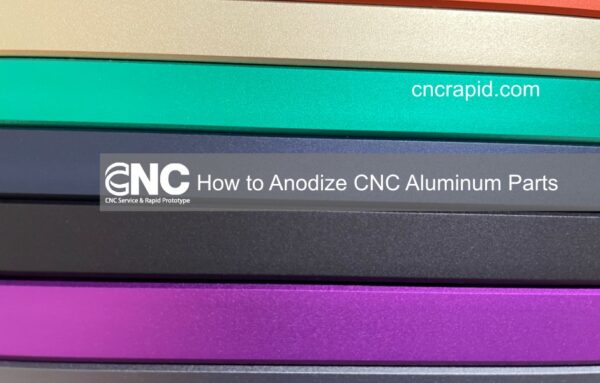

Understanding Anodizing

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Aluminum is especially suited for anodizing, and the result is a layer that is not applied to the surface like paint or plating, but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel. This layer is also highly porous in its initial stages, allowing for the introduction of dyes that can impart vibrant colors to the metal. Red anodized aluminium is particularly popular for its vivid appearance and the added layer of protection it provides.

Advantages of Red Anodized Aluminum Parts

Durability: The anodized layer is exceptionally hard, making red anodized aluminium parts incredibly resistant to scratches, wear, and tear, extending the lifespan of products significantly.

Corrosion Resistance: The anodizing process enhances the natural corrosion resistance of aluminum. Red anodized parts can withstand harsh environmental conditions without corroding, making them ideal for outdoor applications.

Aesthetic Appeal: The striking red color achieved through anodizing is not only visually appealing but also offers a uniform finish that can elevate the look of any product. This makes it a favored choice for industries where both form and function are critical.

Improved Adhesion: The porous nature of the anodized layer improves adhesion for glues and bonding agents, making it easier to combine with other parts in assembly processes.

Electrical Insulation: Anodizing provides excellent electrical insulation, making red anodized aluminum parts suitable for electronic and electrical applications.

Applications

The unique properties of red anodized aluminium parts make them suitable for a wide range of applications. In the consumer goods industry, they are used for components that require durability, corrosion resistance, and aesthetic appeal. The automotive sector utilizes them for decorative trims, performance parts, and in areas requiring heat resistance. Consumer electronics manufacturers employ red anodized aluminum for durable and aesthetically pleasing casings. Additionally, these parts are also found in sporting goods, medical devices, and custom machined parts where appearance and performance are paramount.

Why Choose CNC Rapid?

At CNC Rapid, we pride ourselves on our precision CNC machining capabilities and our expertise in producing high-quality red anodized aluminium parts. Our advanced equipment and skilled technicians ensure that every part meets the highest standards of quality and precision. By choosing CNC Rapid, you are not only getting a product; you are also gaining a partner dedicated to supporting your success through innovation, quality, and service.

Red anodized aluminium CNC machining parts offer a unique combination of beauty, durability, and functionality. Whether you’re developing products for the consumer goods industry, automotive, electronics, or any other sector, CNC Rapid can help you harness the full potential of red anodized aluminum. With our commitment to excellence and innovation, we are ready to help you achieve your manufacturing goals and bring your ideas to life.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!