How to Anodize CNC Aluminum Parts? Anodizing, an electrochemical process, not only bestows aluminum components with a robust exterior but significantly enhances their durability by amplifying their resistance to corrosion and wear. In the realm of CNC aluminum parts manufacturing, this process is pivotal as it provides superior adhesion for paint primers and glues than bare metal. This article delves into the various stages of anodizing, offering practical tips and advice.

1. Understanding Anodizing

Anodizing transforms the metal surface into a high-performance aluminum oxide finish through an electrochemical process. This not only bolsters the component’s resistance to corrosion and wear but also enhances its versatility by providing better adhesion for paint primers and glues.

2. Detailed Steps of Anodizing

- Beadblasting: Initially, aluminum parts need to be beadblasted to remove all machining marks. Specifically, glass beads with a grit of #120 are utilized during beadblasting to ensure a uniform and smooth finish on the parts.

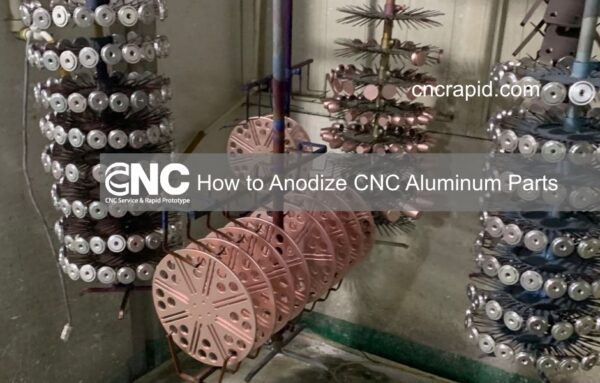

- Part Fixation: Securing the parts with jigs and racks throughout the process is crucial, as improperly racked parts might fall into the tank.

- Cleaning: Subsequently, the parts are cleaned to remove machining oils by submerging the aluminum into an alkali or acid-based detergent tank, followed by rinsing to prepare for the next step.

- Etching: The parts are then etched to prepare for the anodizing progress, removing a slight thickness from the part. Another rinse prepares it for the next step.

- Desmutting: The next phase involves desmutting to eliminate inclusions like zinc.

- Anodizing: The principal step of anodizing involves immersing the aluminum into a tank of sulfuric acid electrolyte while an electric current is passed through the medium. A cathode is mounted inside the anodizing tank, while the aluminum extrusions act as an anode.

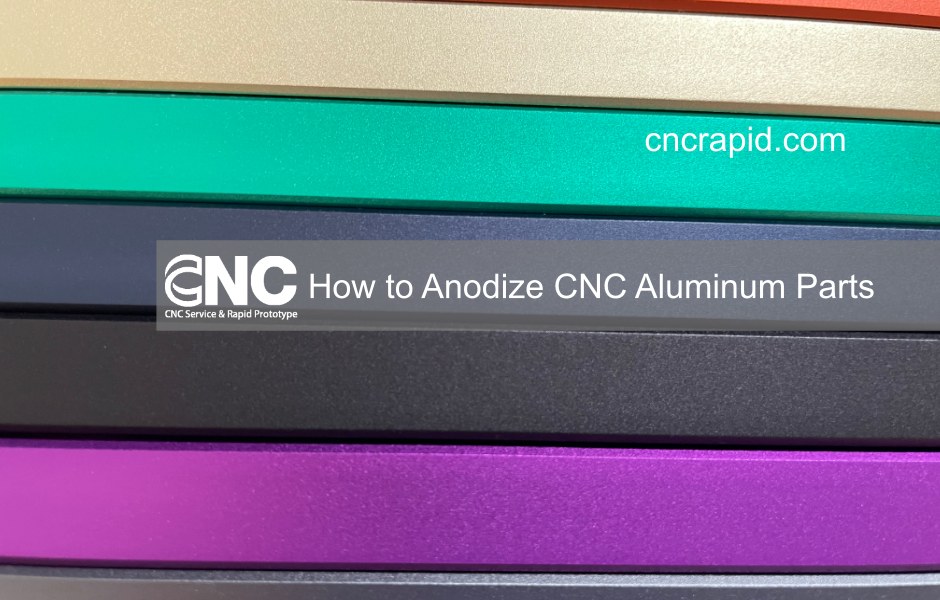

- Coloring: Post-anodizing, the surface is of a porous structure, and dissolved metal salts or organic dyes can be introduced into the open pores to create various shades.

- Sealing: The final step involves sealing the porous surface using a nickel acetate solution, providing a uniformly sealed surface.

Anodizing not only enhances the physical properties and durability of CNC aluminum parts but also amplifies its aesthetics and functionality by providing a sturdy external coating. By understanding and mastering each stage of anodizing, engineers and product designers can formulate manufacturing strategies with precision, ensuring the final product adheres to the highest standards of quality and performance.