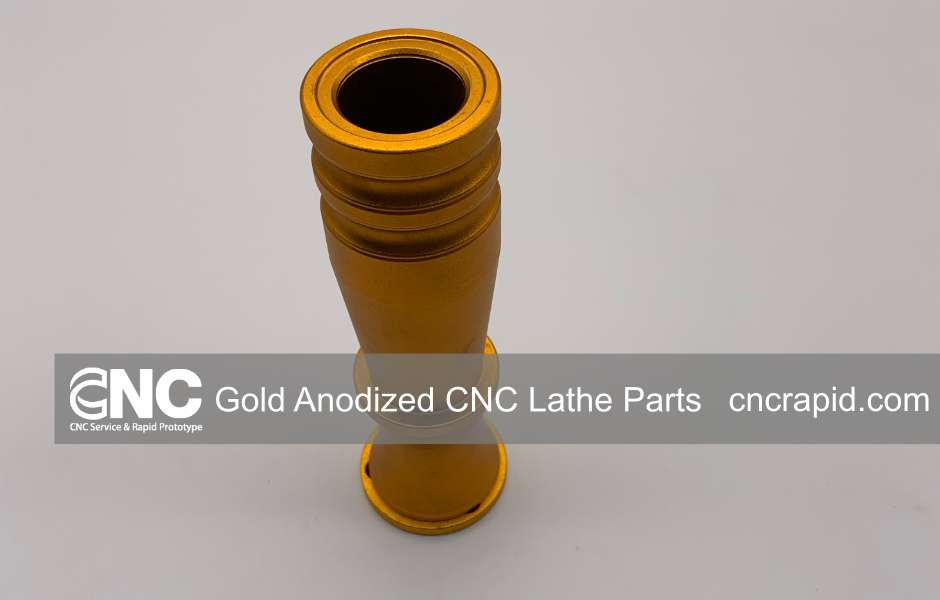

At CNC Rapid, we specialize in producing high-precision CNC lathe parts tailored to meet your exact specifications. Today, we’re showcasing a custom aluminum part finished with a stunning gold anodized coating — a perfect combination of performance, durability, and visual appeal.

What Is Gold Anodizing?

Gold anodizing is a surface treatment process where aluminum parts are electrically oxidized to create a protective oxide layer, which is then dyed gold. This process not only enhances the corrosion resistance of the part but also gives it a luxurious and professional appearance. It’s a popular choice for components in electronics, aerospace, robotics, and high-end consumer products.

CNC Turning Meets Decorative Finish

The parts featured here are precision-turned from aluminum using our CNC lathes. Every detail, from the threading to the surface finish, is controlled to tight tolerances. After machining, the part undergoes a gold anodizing process, resulting in a vibrant, wear-resistant finish.

Why Choose Gold Anodized CNC Lathe Parts?

- Enhanced durability: Anodizing increases surface hardness and corrosion resistance.

- Improved aesthetics: The gold color adds a premium look ideal for visible components.

- Electrical insulation: Anodized aluminum provides non-conductive properties, useful in electronics.

- Lightweight performance: Aluminum is strong yet lightweight, perfect for precision assemblies.

Benefits of CNC Lathe Machining

CNC lathes offer a range of advantages that make them an essential part of modern manufacturing:

- High precision and repeatability: Ideal for complex geometries and tight tolerances.

- Efficient production: Capable of producing high volumes of parts with consistent quality.

- Reduced lead time: Automation speeds up the process from design to final product.

- Versatility: Suitable for various materials including aluminum, brass, steel, and plastics.

- Cost-effective: Minimizes material waste and reduces the need for secondary processing.

Applications of Gold Anodized Aluminum Parts

These parts are often used in:

- Consumer electronics housings

- Precision instruments

- Custom robotics assemblies

- Decorative hardware

Whether you need a one-off prototype or large-scale production, CNC Rapid can help bring your designs to life with high-quality materials and surface finishes that stand out.

CNC Rapid – Your Trusted CNC Machining Partner in China

Want to learn more about our CNC turning services or anodizing options? Contact us today for a quick quote or technical consultation.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!