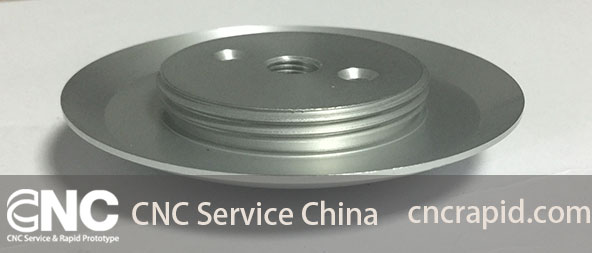

CNC precision turned components are an integral part of many industries, providing highly accurate and intricate parts that meet the demanding requirements of various applications. These components are produced using advanced CNC turning technology, which ensures exceptional precision, quality, and consistency.

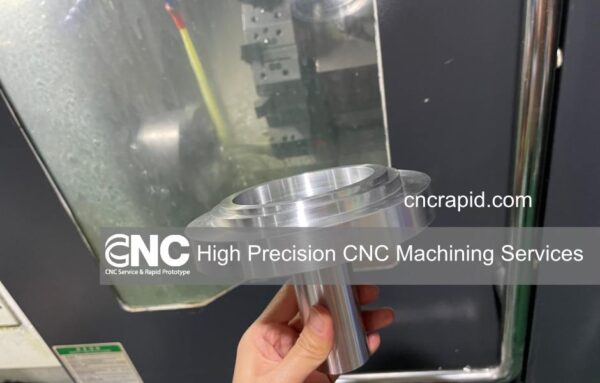

CNC precision turning is a manufacturing process that uses computer-controlled lathes to create parts with extremely tight tolerances and intricate details. The CNC lathe follows programmed instructions to rotate the workpiece while cutting tools remove material to create the desired shape. This process enables the production of complex parts with high precision and accuracy, making it ideal for a wide range of applications.

Advantages of CNC Precision Turned Components

- High precision and accuracy: CNC precision turned components boast exceptional precision and accuracy, ensuring that the parts meet the demanding requirements of various industries.

- Consistency: CNC precision turning ensures consistent production of identical parts, making it suitable for large-scale manufacturing runs where uniformity is crucial.

- Rapid production: CNC machines can operate continuously and quickly, resulting in reduced production times and faster turnaround for customers.

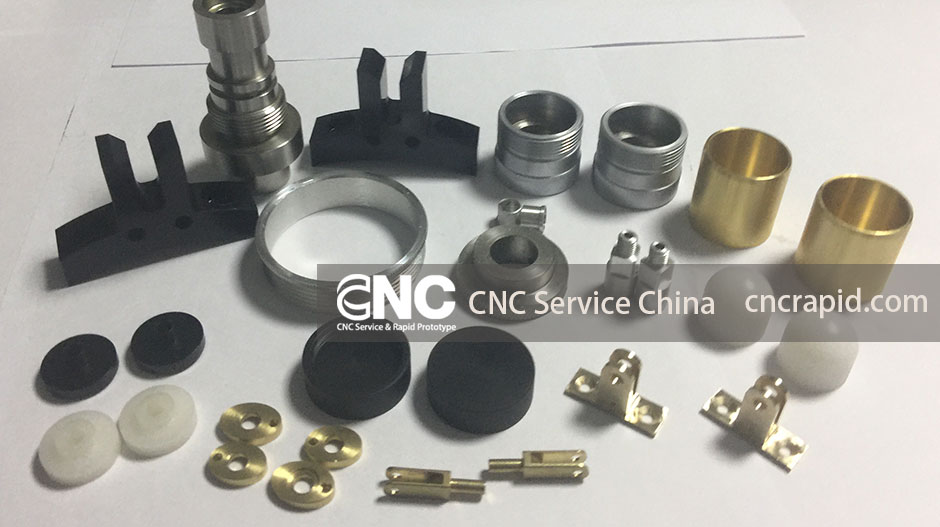

- Material versatility: CNC precision turned components can be produced from a wide range of materials, such as aluminum, stainless steel, brass, copper, and plastics, catering to the specific needs of various industries and applications.

Precision turned components factory in China. We specialized in CNC machining services, CNC turning and CNC milling services. Precision CNC machined parts made from turned or milled plastic and metal components.

We offer the wide range of CNC machining parts and we are open to manufacturing custom CNC machining parts as per your unique requirements. CNC machining services feature personalized customer service for made-to-order parts and components. We offer turning, milling, drilling, tapping, boring, and grinding for a variety of materials.

Precision turned components factory

With the ability to employ our advanced CNC machining services to a broad variety of applications, such as engine and hydraulic components, shafts, sockets, and castings, we have happily served multiple industries, including energy, food processing, and machinery.

|

|

CNC machining is a practical option for everything from prototype manufacturing to production runs. We are a one-stop shop for custom machining and manufacturing.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Get in Touch

If you need Metal & Plastic parts machined for rapid prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!